MegaWatt Monday

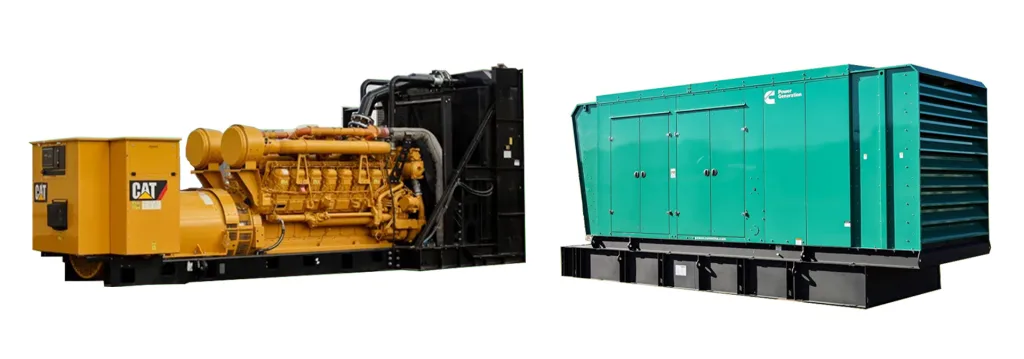

Generator Source offers a comprehensive selection of 1000kW to 4000kW generators for sale, serving businesses that require high-capacity power solutions. Our inventory covers both new and used units across this multi-megawatt range, with options in diesel and natural gas configurations. Whether you need reliable standby backup or continuous prime power, we have large-scale generator systems ready to meet your requirements, all load-tested and inspected for performance you can trust.

Just In

Showing 1 of 1 results

- More Details

Three-Phase

Fuel: Diesel

Loc: Jacksonville

Built: 2006

Volts: 277/480v

Hours: 383

Unit #: 093010

Just Sold / Case Studies

Showing 4 of 4 results

-

Sold Details / Case Study

Three-Phase

Fuel: Diesel

Loc: Brighton

Built: 2009

Volts: 13800

Hours: 691

Unit #: 091894

-

Sold Details / Case Study

Three-Phase

Fuel: Diesel

Loc: Brighton

Built: 2009

Volts: 277/480

Hours: 401

Unit #: 088977

-

1000kW Cummins

Three-Phase

Fuel: Diesel

Loc: Brighton

Built: 2024

Volts: 277/480

Hours: 0

Unit #: 071439

-

1000kW Kohler

Three-Phase

Fuel: Diesel

Loc: Brighton

Built: 2006

Volts: 277/480

Hours: 459

Unit #: 092808

Extensive Inventory of 1000kW-4000kW Generators

Our multi-megawatt generator inventory includes a wide range of output sizes from 1 MW up to 4 MW, with both new and quality-used units available to fit various budgets and project scopes. We carry an assortment of heavy-duty diesel generators (known for their high power density and reliability) as well as natural gas generators (preferred for cleaner emissions and continuous fuel supply) in this capacity range. These large-scale generators are offered in standby models for critical backup power, as well as prime-rated units for continuous duty. Every generator undergoes thorough inspection, refurbishment, and load bank testing to ensure it will perform reliably when your facility needs it most.

Generators in the 1000–4000 kW range are engineered to provide dependable power for extremely demanding applications. Many units come mounted in robust weather-proof or sound-attenuated enclosures, often with integrated high-capacity fuel tanks for extended runtime. Others are skid-mounted or containerized for easier transport and deployment. For facilities requiring multi-megawatt output, multiple generators from our inventory can be configured in parallel with load-sharing controls, allowing you to build redundant, scalable power plants that automatically balance load and provide N+1 reliability. Whether you need a single 2MW diesel standby for a data center or a set of 1.5MW generators working in unison for a utility project, we have solutions ready to ship and install.

Search for Megawatt generators

Shop by Capacity Range

Need help finding a generator?

Not sure where to start with a large power system? Our team is here to help. High-capacity generator projects involve many factors – from sizing and site preparation to compliance – so it’s wise to consult with our experts (and your electrical engineers) early in the process. We can assist in selecting the optimal unit or paralleling setup and ensure all technical requirements are met before purchase and installation.

MegaWatt Case Studies and Articles

Case Study – Engineering a 1000kW Custom-Contained Power Module

Custom Commercial Generators When a standard generator installation isn’t an option, Generator…

Parallel Operation of Generator Sets

Utility & Backup Power Nuclear Power Plant Control Room As the world becomes more reliant on ele…

Recent Advances in Diesel Engines & Diesel Generator Sets

Introduction to Diesel Engine Development The diesel engine was developed over a century ago and was…

Caterpillar 2250 kW Diesel Generators: 4.5 Megawatt Power Plant Package

This power plant package features two Caterpillar 2250 kW diesel generators equipped with Cat 3608 e…

Site Planning for an Industrial Generator Installation

Construction Site Planning Purpose This article explores different options available for various typ…

How to Select the Correct Automatic Transfer Switch

Deciding Factors Industrial Electrical Motors Powering Pumps There are a number of different factors…

Industries that rely on 1000kW-4000kW generators

Healthcare & Medical Facilities

Major hospitals, surgical centers, and healthcare campuses rely on large standby generators in the 1–3MW range to power life-saving equipment, critical lighting, HVAC, and backup systems during outages. It’s common for hospital networks to install multiple 1500kW or 2000kW diesel generators in parallel (with automatic transfer switches) to meet strict NFPA 110 emergency power standards and ensure uninterrupted care.

Utilities & Municipal Infrastructure

Electric utilities, grid operators, and municipal facilities use high-capacity generators for both planned and emergency support. Peaking power plants may consist of multiple 2MW–3MW units synchronized to the grid to supply extra capacity during demand spikes. Utility substations and water treatment plants often keep a 1000+kW standby generator on site to maintain critical services if the grid power is lost. These systems must meet stringent reliability and emissions standards while being capable of instantaneous load acceptance to keep public infrastructure running.

Large-Scale Manufacturing & Industrial

Big manufacturing plants, steel mills, automotive factories, and semiconductor fabs often have significant emergency power needs. A sudden outage can halt production lines and cause millions in losses. Facilities like these install industrial standby generators (1500kW, 2000kW, or larger) to cover essential loads – from assembly line machinery and robotics to industrial HVAC and safety systems. Some factories also use large generators for peak shaving or as prime movers in off-grid operations. These generators are integrated with facility power management, kicking in automatically to keep critical processes running and maintain product quality during power disturbances.

Data Center & IT Infrastructure

Data centers, cloud computing facilities, and telecom hubs demand ultra-reliable backup power. These sites often deploy banks of 1MW–2MW generators (typically diesel) in N+1 or N+N configurations to protect servers, cooling systems, and network operations. A single large data center can require 10+ MW of standby power, achieved by running several high-kW gensets in unison. These generators are ready to start within seconds of a utility failure, safeguarding data integrity and uptime commitments.

Oil & Gas Operations

Remote oil and gas operations, such as drilling rigs, natural gas processing facilities, and pipeline pump stations, rely on large generators for primary and backup power. In oilfields, diesel gensets of 1–1.5MW are commonly used to power drilling equipment and camp facilities. At gas sites, natural gas-fired generators (often in the 1000–2000kW range) can leverage the available fuel for efficient prime power. Reliability is critical in these harsh environments; multiple units may run in parallel to ensure there’s always power to prevent downtime, protect equipment, and avoid flaring or safety incidents.

Mining & Heavy Indsutry

Mining sites and heavy industrial operations in remote locations frequently depend on high-capacity generator systems as their primary power source. For example, an open-pit mine or mineral processing plant might operate a “island” power station of multiple 1.25MW diesel generators to run draglines, crushers, conveyors, and camp facilities. Reliability and fuel availability are key – on-site fuel storage and redundant generator capacity are used to ensure 24/7 operation in areas with no grid connection. Even in grid-connected heavy industries, multi-megawatt standby generators are deployed to protect sensitive continuous processes (like chemical production or smelting) against outages that could otherwise cause equipment damage or safety hazards.

Understanding High-Capacity Power Needs (1000kW–4000kW)

Power outages can lead to significant financial losses, data corruption, and damaged reputations. Our range of 1000-4000kW generators provides robust, reliable backup power, ensuring your business operations, critical systems, and revenue streams remain uninterrupted.

What types of facilities typically utilize 1000kW–4000kW generators?

Generators in this range are ideal for large-scale commercial, industrial, and institutional applications that require substantial backup or prime power. This includes major data centers, large hospitals and healthcare campuses, expansive manufacturing or processing plants, college/university campuses, airports and transit hubs, utility companies, and critical government or military installations. Essentially, any operation where a power outage would cause significant financial loss, safety issues, or service disruption may need a multi-megawatt generator solution.

Should I use one large generator or multiple smaller generators in parallel?

It depends on your reliability and scalability needs. A single large generator (e.g. one 2000kW unit) offers a simpler installation and smaller footprint, but it represents a single point of failure. Using multiple generators in parallel (for example, two 1500kW units to supply ~3000kW) can provide built-in redundancy – if one genset fails or is down for maintenance, the others can still carry part of the load. Paralleling smaller units also allows more flexibility; you can start/stop units based on load demand, improving fuel efficiency for varying loads. Many data centers and hospitals prefer an array of generators (with automatic load-sharing controls) to achieve an N+1 configuration, rather than one huge machine. However, a single larger genset might be more cost-effective and maintenance-friendly in some cases. Generator Source can help design the optimal solution, whether that’s one big unit or a coordinated multi-unit system with the switchgear to match your facility’s requirements.

What is the difference between standby and prime power ratings for large generators?

Generator sets are rated based on their intended use and allowable run time:

- Standby Power: Rated for emergency backup use during utility outages. Standby generators can supply full nameplate kW output (and often a 10% overload for a short duration) but are not meant to run continuously. They typically have a limited annual hour usage (e.g. for testing and actual outages) and a higher output rating than the same unit’s prime rating. Standby is ideal for backup-only scenarios, such as a 2MW unit that only runs when the grid fails.

- Prime Power: Rated for primary power use for an unlimited number of hours at variable load. Prime-rated generators are designed to be a regular source of power (for example, at a remote mine or off-grid facility). The prime rating is usually slightly lower than the standby rating for the same generator model, to ensure durability. Prime units can also typically handle a 10% overload for 1 hour in 12 (per ISO standards).

- Continuous Power: Similar to prime in that it’s unlimited hours, but at a constant load. Continuous rating is generally used for applications like base-load generation where the generator runs at a steady output (no significant load fluctuations). Continuous-rated output is often slightly less than the prime rating and does not allow overload capacity.

If your generator will only run during emergencies, choose a standby rating (higher output in a pinch). If it will run as a main power source for long periods, go with a prime rating (or continuous if the load is steady). Always consult the manufacturer ratings and your usage scenario – selecting the proper rating ensures the generator’s engine longevity and compliance with warranty conditions.

How do I determine the right size and configuration for a multi-megawatt generator system?

Accurate sizing is crucial to ensure your generator system can handle your facility’s load without over-sizing (which wastes fuel) or under-sizing (which risks overload). Our team conducts a detailed load analysis as part of the sizing process, which includes:

- Identifying Critical Loads: We itemize all equipment and systems that must have power during an outage (e.g. servers, emergency lighting, UPS systems, chillers, elevators, fire suppression, etc.). This establishes the baseline kW/kVA requirement.

- Calculating Starting Surge Currents: Large motors and HVAC compressors can draw 2-3 times their running current on startup. We account for these inrush currents to ensure the generator can handle the highest surge (measured in kVA) when everything kicks on.

- Assessing Running Load: We total the continuous running amperage of all anticipated loads. This includes factoring in load diversity (not all equipment may run at 100% at once) and any power factor considerations for the facility.

- Considering Future Expansion: It’s wise to include headroom for growth. If you plan to add more machinery or if load may increase, we recommend sizing slightly above current needs or designing a system where additional generators can be added later (modular paralleling).

For very large installations, we may also evaluate if using multiple generators dividing the load is better than one unit, as discussed above. Our goal is to provide a generator or generator system that can supply your highest expected load comfortably, without frequent overload alarms or wet-stacking from underloading a too-large unit. We encourage engaging with our Generator Source specialists early in the design phase – we can perform on-site power assessments and work with your engineers to determine the optimal size and number of generators for your operations.

What are the benefits of investing in a 1000kW–4000kW generator for my business?

A large-scale generator system is a significant investment, but it directly protects your business in critical ways:

- Uninterrupted Operations: Maintain full productivity and avoid downtime during grid failures. Your employees can keep working and essential processes continue running, even in a blackout.

- Revenue and Asset Protection: Prevent the massive financial losses that can result from halted production lines, closed data centers, spoiled inventories, or lost transactions. For example, a data center outage can cost thousands per minute – a generator ensures revenue isn’t lost.

- Safety and Compliance: Ensure life-safety systems (lighting, alarms, fire pumps) and critical environment controls (ventilation, cooling) remain active during emergencies, keeping occupants safe. In many industries (healthcare, telecom), backup power isn’t just smart – it’s required by code or SLAs.

- Data and Equipment Security: Avoid corruption of critical data and prevent damage to sensitive equipment from sudden power loss. Generators, along with UPS systems, keep servers, networks, and industrial controls powered smoothly until normal power is restored.

- Reputation and Reliability: Demonstrate to clients, customers, and partners that your business is prepared and resilient. Fulfilling commitments on time and maintaining services through a crisis can give you a competitive edge.

- Potential Insurance Benefits: Some insurers offer better rates or incentives for businesses with robust disaster mitigation in place. Having an emergency power system could reduce insurance claims and premiums related to power outage damages.

Is diesel or natural gas a better fuel choice for generators of this size?

Both diesel and natural gas (NG) generator sets are common in the 1MW+ class, and each has advantages:

- Diesel Generators: Diesel is the traditional choice for large standby generators. Diesel engines provide high power output and excellent step-load performance (handling large load additions quickly). Fuel can be stored on-site in large tanks for emergencies, which adds to reliability – critical for life-safety and mission-critical backup. Modern diesels are highly efficient under heavy loads and are built to run long hours if needed. The downside is diesel fuel requires maintenance (stabilizers, regular testing) and emissions are higher (Tier 2 to Tier 4 Final standards apply for new units). For many high-priority applications (data centers, hospitals), diesel’s reliability and immediate response make it the preferred option.

- Natural Gas Generators: Natural gas-fueled generators in the 1000–2000kW range have become more popular for both backup and prime power, especially where a utility gas pipeline is available. NG generators produce fewer exhaust particulates and generally have longer run times in an outage because they aren’t limited by on-site fuel tank capacity. They are ideal for facilities in urban areas with strict emissions rules or where refueling diesel is impractical. NG units can also be cost-effective for prime power due to lower fuel cost per kWh in many regions. However, they depend on the gas supply (which can be cut in disasters), and their transient response can be slightly slower than diesel (often mitigated by using oversizing or adding an on-site propane backup supply in dual-fuel setups).

Many organizations choose diesel for standby applications requiring the fastest response and highest reliability, while natural gas is favored for long-duration runs or environmental compliance. We offer high-quality generators in both fuel types and even bi-fuel/dual-fuel models that can give a mix of diesel reliability and gas fuel economy. Our experts can help evaluate your site – including fuel availability, environmental regulations, and runtime needs – to recommend the best fuel option for your 1MW+ generator.

What features should I look for in a high-capacity generator system?

Modern large generators come with advanced features and auxiliary systems that are important to consider:

- Paralleling & Load Sharing Gear: If you plan to use multiple generators together, look for integrated paralleling controllers or compatibility with external switchgear. Paralleling generators requires sophisticated controls to sync frequency, balance loads, and automatically shed or add units as needed. Many of our multi-megawatt systems include load-sharing control panels or can be provided with custom switchgear for seamless parallel operation.

- Automatic Transfer Switch (ATS): An ATS is essential for standby installations – it detects outages and transfers load to the generator(s) automatically. For large systems, there may be multiple ATS units or a closed-transition switchgear setup to manage various load circuits. Ensure the ATS is rated for your voltage and amperage, and consider bypass isolation ATS for critical facilities to allow maintenance without power disruption.

- Advanced Digital Controller: High-end generators feature digital control modules that monitor generator output (voltage, frequency), engine parameters (oil pressure, coolant temp), and perform safety shutdowns on faults. These controllers often include event logging and can communicate with building management systems. They make operation and troubleshooting much easier.

- Remote Monitoring & Management: For 24/7 facilities or unmanned sites, remote monitoring capability is a big plus. Using either an Ethernet/IP connection or cellular modem, your generator can send alerts and provide status to your computer or smartphone. Generator Source offers solutions that let facility managers monitor multiple generator sets across various locations from a single dashboard – ensuring you’re informed immediately if there’s an issue or an outage triggers your equipment.

- Sound Attenuation: Large generators can be noisy (80+ dBA). If your location is near populated areas or sound-sensitive environments (like hospitals or offices), look for units with sound-attenuated enclosures or containers. These include special acoustic insulation, critical-grade mufflers, and airflow baffles to reduce noise levels, often to meet local noise ordinances.

- Emission Control Systems: Meeting emissions regulations is crucial, especially for prime power or non-emergency use. Newer diesel generators may come with after-treatment systems like Diesel Particulate Filters (DPF) or Selective Catalytic Reduction (SCR) to achieve Tier 4 Final emissions compliance. Natural gas units might include three-way catalytic converters for clean exhaust. Ensure any generator you consider is compliant with the EPA and local air quality rules for its intended service (Emergency Standby has different rules than prime).

- Load Bank Testing Provisions: Periodic testing at full load is important for standby generator health. Many large generators have built-in load bank connections or can be supplied with load bank units. This feature allows you to regularly verify that the gen set can handle its rated load and burn off any fuel deposits (especially critical for diesel sets that otherwise run lightly loaded).

- Cold Weather & Reliability Accessories: If your generator will operate in cold or harsh climates, look for features like jacket water heaters, battery warmers, and thermostatically controlled enclosure heaters (cold weather kits). These ensure the engine starts reliably in sub-freezing conditions. Additionally, features like dual starter motors and redundant fuel transfer pumps can add reliability for mission-critical systems.

Our sales team can walk you through these and other features – such as fuel level monitoring, fire suppression in enclosures, or custom PLC-based controls – to make sure the generator you choose is fully equipped for your operational needs.

How long do generators in this class last, and what about maintenance and warranty?

With proper maintenance, a high-quality 1MW+ commercial generator is a long-term asset, often providing 15–30 years of service or tens of thousands of operating hours. Many of the Caterpillar, Cummins, or MTU units we refurbish from the 1990s and 2000s are still going strong today in second-life installations. Key factors that influence lifespan include:

- Manufacturer Quality: Top-tier brands (e.g. Caterpillar, Cummins, MTU, Kohler) build generators specifically designed for heavy-duty, sustained use. These models feature robust engines, high-grade alternators, and controls built to withstand rigorous duty cycles.

- Maintenance Schedule: Adhering to the manufacturer’s recommended maintenance is paramount. This means regular oil and filter changes, coolant flushes, fuel system servicing, battery inspections, and exercising the generator under load periodically. Generator Source offers preventative maintenance plans to keep your unit in peak condition. Well-maintained engines avoid wet-stacking, fuel contamination, and undue wear.

- Usage Pattern: Standby generators (light hours, periodic testing) tend to last many years since they run infrequently. Prime power generators (running daily) will have a shorter calendar lifespan simply due to accumulating hours, though they are built for it. Running at proper load (not consistently maxed out or conversely not underloaded) will maximize engine life. We match customers with the right rating (standby vs prime) to align with how they will use the generator.

- Environment: Indoor installations or units in climate-controlled enclosures may age better than those exposed to harsh weather or corrosive environments (coastal salt air, for example). We can provide enclosures, coatings, or upgraded components (stainless steel hardware, etc.) if your location demands it.

- Upgrades & Rebuilds: Because these generators are a large investment, it’s common to perform engine rebuilds, alternator rewinds, or control system upgrades at mid-life to extend their service. Parts availability from major manufacturers can exceed 20+ years. Generator Source’s technicians are experienced in complete overhauls of large generators – often a cost-effective alternative to new replacement after a decade or two of use.

When you purchase a new generator from us, it will typically include a manufacturer’s warranty (e.g. 1 to 2 years standard, with options to extend). Our used and surplus units also come with warranty coverage from Generator Source, and all units pass our 31-point inspection for quality assurance. In short, these generators are built to last, and with the right care, they will provide reliable power for decades.

What are the key installation requirements for a 1000kW–4000kW generator?

Installing a large industrial generator is a major project that must consider safety, code compliance, and logistical factors:

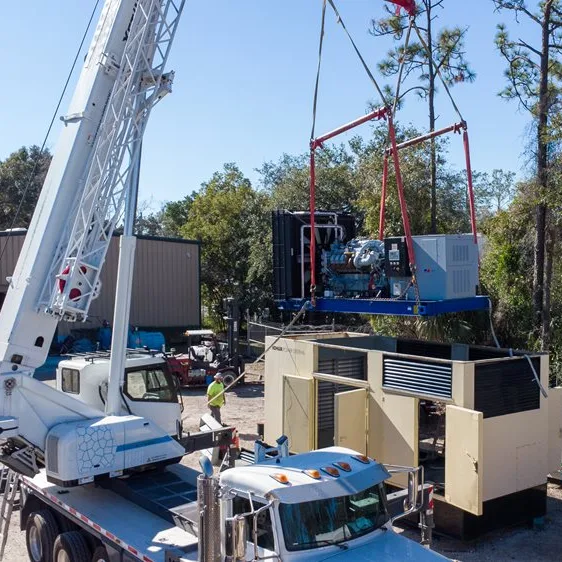

- Site Selection & Preparation: A thorough site survey is the first step. The generator should be placed on a secure, accessible location with proper clearances. Typically, a large concrete pad (engineered for the generator’s weight and vibration dampening) is poured as a foundation. For rooftop installations (sometimes done in dense urban areas for hospitals or telecom), structural analysis is needed. Ensure the site allows for truck/crane access for delivery and future service.

- Permitting & Codes: Work with local authorities to obtain the necessary permits. Large generators fall under building and fire codes, often requiring submission of plans. You’ll need to comply with local noise ordinances, environmental regulations (air quality permits for fuel storage and emissions), and any zoning restrictions. NFPA 110 standards apply if it’s an emergency system. Our team is familiar with these processes and can assist in providing documentation and coordination.

- Fuel Storage & Delivery: Proper fuel system integration is critical. Diesel generators will need an appropriate on-site fuel storage tank (above-ground or below-ground) with spill containment and ventilation, sized for the desired runtime (often 24–72 hours worth of fuel). Fuel piping and pumps must meet fire code (NFPA 30/37) and EPA regulations. Natural gas units need a sufficient gas service line and regulator; coordination with the gas utility is required to ensure adequate pressure and flow. In some cases, backup propane supply or a redundant fuel source might be planned for resiliency.

- Electrical Integration: The generator must tie into your facility’s electrical system via an automatic transfer switch or switchgear. A licensed electrician will install appropriate cabling, conduits, and protection (breakers, relays). For large generators, especially those at medium voltage (e.g. 4160V or 13.8kV outputs), special switchgear and possibly a step-down transformer may be needed to interface with your building’s distribution voltage. Proper coordination and testing of the protective relays and breaker settings is important to ensure safety and prevent backfeeding.

- Cooling & Ventilation: Large gensets produce substantial heat and exhaust. If the unit is indoor or in a powerhouse, you’ll need adequate ventilation (motorized louvers, intake/exhaust fans) to dissipate heat and provide combustion air. The exhaust system must be routed outdoors and often includes hospital-grade silencers to reduce noise. Ensure exhaust outlets meet clearance requirements from building openings and combustible materials, and consider installing exhaust after-treatment (if required by code or to reduce diesel odor).

- Startup & Commissioning: Once installed, the system should be commissioned by qualified technicians. This includes initial fuel fill and leak checks, battery setup, verifying all control wiring, and performing a load bank test. During commissioning, the generator is run under load to confirm it can carry the expected demand and that all automatic functions (startup, transfer, shutdown) work properly. We also train your facilities personnel on routine operation and emergency procedures as part of our installation support.

By addressing these factors – from the concrete pad to the exhaust stack – you ensure a safe installation that will serve reliably. Generator Source can provide turnkey installation support, or work closely with your contractors, to make the process smooth.

Are there specific compliance standards or certifications for big commercial generators?

Yes, deploying a 1000–4000kW generator must be done in accordance with various standards and regulations to ensure safety and compliance:

- NFPA 110 (and NFPA 99 for healthcare): NFPA 110 is the Standard for Emergency and Standby Power Systems, which outlines requirements for installation, testing, and maintenance of emergency generators. Hospitals and critical care facilities, for example, must meet NFPA 110 Level 1 standards (generator start within 10 seconds, etc.). If your generator supports life safety loads, it falls under this standard. NFPA 99 provides criteria for healthcare facilities’ electrical systems, including generator backup for essential circuits.

- UL Listings: The generator and its switchgear/transfer switch should be UL-listed for the intended application (e.g. UL 2200 for stationary engine generator assemblies). UL listing ensures the equipment meets electrical safety standards. Many project specifications require UL2200 certified generators, which all of our new units are, and many of our refurbished units can be field certified if needed.

- EPA Emissions Regulations: Large generator engines are subject to U.S. EPA emission standards based on their horsepower and whether they are emergency or non-emergency use. For diesel engines in this size, Tier 2 or Tier 3 standards often applied for standby units (emergency use), while prime (non-emergency) units manufactured in recent years must meet Tier 4 Final unless exempt. We can guide you on the applicable EPA rules (40 CFR Part 60 Subpart IIII for diesels, Subpart JJJJ for gas engines) and ensure any generator you purchase has the required emissions certification or retrofit kits.

- Local Air Quality Permits: In addition to federal EPA rules, states (and air quality management districts) often require permits for large generator installations, especially if fuel storage or emissions could impact the environment. For instance, California’s Air Districts have stringent permitting for standby generators to control NOx, CO, and particulate matter output. Make sure to obtain any required air permits before installation – running a generator without a permit can result in fines. We provide emissions specs and documentation to help with permit applications.

- OSHA and Safety Standards: Occupational safety regulations apply to the installation and operation of generator systems. This includes proper signage, electrical clearance, exhaust routing, noise exposure for personnel, and safe fuel handling. If the generator is in an enclosure or dedicated room, NFPA 37 (for fuel systems) and NFPA 70 (National Electrical Code) parts are relevant. An important NEC requirement, for example, is that the emergency system wiring is segregated from other wiring. We design installations to be OSHA-compliant, ensuring things like hot surfaces are guarded and maintenance access is safe.

- Building & Electrical Codes: Lastly, all local building codes and the NEC (National Electrical Code) must be followed. This covers everything from the concrete pad construction to the grounding of the generator and transfer switches. Many large generators are installed as “Service Entrance Rated” systems, which has special bonding and breaker requirements. We ensure that our solutions meet or exceed the relevant codes and we can coordinate with your local inspectors to get final approval.

By adhering to NFPA, UL, EPA, and local codes, you not only stay within the law but also ensure your generator system will operate safely when needed. Generator Source has extensive experience in compliant installations across the U.S. and can assist with navigating these standards.

Why should Generator Source be my preferred partner for a 1000kW–4000kW generator project?

Generator Source stands as a leading provider of robust high-capacity power solutions. We have decades of specialized experience with industrial generators, and we strive to add value at every step of your project:

Proven Track Record: With 50+ years of industry experience, Generator Source has successfully supplied and installed generators for hospitals, tech companies, municipalities, and Fortune 500 manufacturers alike. We invite you to review our case studies and client testimonials – our reputation is built on reliability, honesty, and customer satisfaction. When you partner with us, you’re choosing a company that will stand behind its equipment and work, long after the sale.

Expert Consulting & Sizing: Our team brings deep industry knowledge to accurately assess your unique power demands. We’ll help you determine the ideal generator size, configuration, and features, ensuring you get a right-fit solution instead of an oversold package.

Vast Inventory Selection: We maintain one of the largest inventories of commercial generators in North America, with over 200 units ranging from 100 kW up to 4000 kW ready to ship. This includes new models from top brands as well as low-hour used and surplus units – giving you plenty of options and price points. You can often find exactly what you need in-stock for immediate delivery, rather than waiting months for a factory order.

Turnkey Project Management: From the initial site assessment and permitting to delivery, installation, and commissioning, we offer end-to-end project support. Our engineers and field technicians can manage rigging and placement of large equipment, coordinate electrical and fuel contractors, and integrate the generator with your facility seamlessly. We understand the complexities of multi-megawatt systems and will ensure every detail is handled, so you can focus on running your business.

Comprehensive After-Sales Support: Owning a generator is a long-term commitment – and we’re here for the long haul. Generator Source provides preventative maintenance programs, genuine OEM parts, and emergency repair service nationwide. Our service teams are EGSA-certified and factory-trained on Caterpillar, Cummins, Kohler, MTU, and more. Whether it’s routine oil changes or a 10-year overhaul, we have the expertise to keep your generator(s) running in peak condition.

Customized Solutions: We recognize that every facility has unique requirements. Our approach is not one-size-fits-all – we can customize enclosures, fuel systems, control schemes, and even build multi-unit power plants tailored to your specifications. Need a containerized 2000kW unit for a quick-deploy data center? Or a synchronization panel to tie three generators together? We excel at delivering bespoke power solutions on time and on budget.

Our Values

Our mission is to provide reliable power solutions that empower businesses across industries, ensuring seamless operations with unmatched expertise and quality.

Since our founding over four decades ago, Generator Source has grown to become the country’s largest buyer and seller of commercial generators, with branches and service teams ready to deliver power solutions nationwide.

People First

We prioritize relationships, building trust and respect in every customer and team interaction.

Quality of work

We hold ourselves to the highest standards, delivering reliable power solutions backed by rigorous testing.

Dedication

We go the extra mile to support our customers and stand behind every generator we service and sell.

Expertise

With 50 years of industry experience, our team brings unmatched knowledge to every project.

Why Choose Generator Source?

- Over 50 years of generator system experience

- Extensive inventory of new and used generators

- Diesel and natural gas options in stock

- Field service teams in Colorado, Florida, and Texas

- EGSA-certified technicians and nationwide shipping

- Load tested, inspected, and ready-to-run inventory

In-Shop and Field Generator Support

If you purchase a 1000kW to 4000kW generator from Generator Source, our support doesn’t end at the sale. We have expert mobile field service teams available to come directly to your site for diagnostics, repairs, and preventative maintenance. Our technicians can respond quickly to minimize any downtime – whether your generator is installed at a data center, hospital, manufacturing plant, or remote industrial site, we have you covered. With service hubs in the Rocky Mountain region, the Gulf Coast, and Central Texas, we provide regional on-site support to keep your high-kW generator running reliably. And at our in-house facilities, we’re equipped with load banks, advanced diagnostic tools, and engine overhaul capabilities to perform everything from routine oil changes to complete engine rebuilds. When you partner with Generator Source, you gain a long-term service partner dedicated to the health of your power system.

Quality Assurance Guaranteed

Certified 31-Point Inspection

Our inventory features both brand-new models and quality-tested used generators. We stock new, used, and surplus industrial generators, giving you flexible options to meet your power needs cost-effectively. Each pre-owned unit undergoes rigorous refurbishment and a multi-point inspection to ensure it performs to specification. We support multiple fuel types in this range, including diesel-powered sets known for their durability and natural gas generators favored for cleaner emissions.