Essential Generator Buyers Guide

Buying an Industrial or Commercial Generator

Choosing and installing an industrial or commercial generator is a significant investment that demands careful planning. Beyond understanding your power needs, navigating environmental factors, relevant regulations, and diverse local ordinances is crucial for a successful, compliant, and reliable installation. This comprehensive guide from Generator Source is designed to equip businesses with the knowledge needed to make informed decisions, ensuring seamless power continuity and regulatory adherence.

Understanding Your Power Needs

The foundation of a successful generator purchase is an accurate assessment of your power requirements. This step carries important considerations for optimal performance. At Generator Source, we specialize in high-quality, reconditioned used diesel generators, and our expertise is built on years of meticulously inspecting, testing, and servicing these powerful machines. Let us help you eliminate the guesswork.

Elevation & Altitude

General Guideline: As a rule of thumb, diesel and liquid propane generators typically experience a 2-3% power derating for every 1,000 feet above sea level. Natural gas generators, which are more sensitive to air density, can see a derating of approximately 4% for every 1,000 feet.

Load Assessment

Before selecting a generator, a detailed load assessment is paramount. This involves calculating the total power (kW) and apparent power (kVA) your critical systems and equipment will draw during an outage. Factors like peak demand, inrush current (for motors), and harmonic distortion (for sensitive electronics) must be considered.

Sizing for Conditions

High altitude significantly impacts generator performance. At higher elevations, the air density is lower, meaning less oxygen is available for combustion and less dense air for cooling. This results in a reduction of the generator’s rated power output, known as “derating”.

Impact on Sizing

This means you’ll need to purchase a larger generator than a similar facility at sea level to achieve the same usable power output. Generator Source’s experts account for these derating factors to ensure your generator is correctly sized for your specific elevation.

Types of Generators for Industrial & Commercial

Standby Power Generators

Designed for emergency backup during utility outages. They operate for limited hours per year. Most commercial and industrial applications fall into this category.

Prime Power Generators

Built for continuous operation as a primary power source, often in remote locations or where grid power is unavailable/unreliable. They are designed for heavier use cycles.

Continuous Power Generators

Similar to prime power, but designed for 100% load continuously. Understanding the expected runtime and load profile is key to selecting the appropriate generator rating.

Fueling Your Generator: Important Considerations

Diesel Generators

Pros: High power density, excellent reliability, and quick startup. Diesel remains a popular choice for critical standby applications.

Cons: Requires on-site fuel storage (tanks), which is subject to stringent regulations. Emissions from diesel generators are also a major regulatory consideration, especially for larger units.

Context: Diesel fuel delivery services are widely available.

Natural Gas Generators

Pros: Offers a continuous fuel supply (if connected to a utility line), eliminates the need for large on-site fuel storage tanks, and generally produces cleaner emissions, making permitting potentially simpler.

Cons: Reliance on the natural gas utility infrastructure (vulnerable to gas line disruptions), and requires sufficient gas pressure and volume for larger units. More significant derating at altitude.

Context: Natural gas infrastructure is often well-developed in urban and many suburban areas, making it a viable option for many businesses.

Propane Generators

Pros: Clean-burning, easily stored in tanks (though less energy-dense than diesel).

Cons: Requires significant on-site tank storage for industrial applications due to lower energy density, and can be less economical for very large or extended run times.

Context: More common for smaller commercial or residential backup, but can be an option for industrial sites with limited run time requirements or remote locations without natural gas access.

Fuel Storage Regulations

Relevant authorities regulate petroleum storage tanks, including aboveground storage tanks (ASTs) and underground storage tanks (USTs), often enforcing codes like NFPA. Local fire departments and environmental agencies will also have specific requirements for fuel tank placement, secondary containment, and spill prevention.

Navigating Regulations & Permitting

Permitting for industrial generators is a multi-layered process involving state, regional, and local authorities. Compliance is non-negotiable.

Environmental Protection Agencies

Air Quality Permits: Most industrial generators require an Air Pollutant Emission Notice (APEN) or a full air permit from relevant environmental divisions. This is particularly true for diesel engines and natural gas engines.

Operating Permits: Very large industrial sources or those with significant emissions may fall under operating permit requirements, which are more complex.

Hazardous Waste: Environmental agencies also regulate hazardous waste generation, relevant for disposal of used oil, filters, and other materials from generator maintenance.

Local Authorities Having Jurisdiction

Building Permits: Your city or county building department will require permits for the generator’s installation (electrical, mechanical, structural). For example, a Generator Installation Permit may be explicitly required for all stationary generators.

Zoning & Setbacks: Local zoning laws dictate where a generator can be placed on your property (e.g., minimum distances from property lines, buildings, or public ways).

Fire Department Approval: Local fire departments have specific guidelines for generator location, fire ratings for indoor generator rooms (e.g., 2-hour fire rating), and fuel storage.

NFPA Standards

NFPA 110 (Standard for Emergency and Standby Power Systems): This crucial standard is widely adopted and enforced. It outlines requirements for generator sizing, installation, maintenance, testing (including monthly load exercising and tri-annual load bank testing), fuel storage, and documentation for critical applications (Level 1 and Level 2 systems).

NFPA 70 (National Electrical Code – NEC): Governs the electrical wiring and connections for generator systems, ensuring safety and proper integration with your facility’s electrical system.

Installation & Site Considerations

Diverse topography and climate present unique challenges and requirements for generator installation.

Climate & Weather Resilience

Cold Starts: Generators need to be equipped with block heaters and battery chargers to ensure reliable starting in cold winter temperatures.

Extreme Heat: Proper ventilation and cooling system design are essential to prevent overheating during hot summers, especially in enclosed spaces.

Snow & Wind: Enclosures must be robust to withstand heavy snowfall and high winds, protecting the unit from elements and ensuring optimal operation.

Noise Ordinances

Industrial generators, especially larger ones, can be noisy. Municipalities have specific noise ordinances that must be met.

Mitigation: High-quality, sound-attenuated enclosures are almost always necessary. Strategic placement, acoustic barriers, and specialized mufflers may also be required.

Examples: Regulations may specify limits like 55 dBA (day) and 50 dBA (night) for residential areas, or 65 dBA (day) / 60 dBA (night) for commercial property lines.

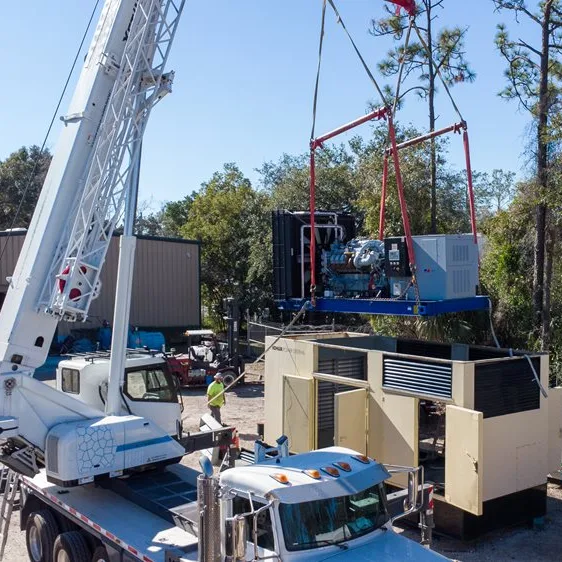

Site Preparation

Foundation: A robust, level concrete pad is essential to support the significant weight of industrial generators and minimize vibration.

Ventilation & Exhaust: Proper air intake for cooling and efficient routing of hot exhaust gases away from the building are critical for performance and safety. This often involves large ducting or specialized stacks.

Accessibility: Ensure sufficient clear space around the generator for routine maintenance, repairs, and fuel delivery. Local regulations may mandate specific clearance distances.

Choosing the Right Generator: New vs. Used

Benefits of New Industrial Generators

- Latest Technology: Includes advanced control systems and superior fuel efficiency.

- Full Manufacturer Warranty: Provides peace of mind and long-term support.

- Emissions Compliance: New diesel units typically meet current emissions standards, which is crucial for permitting.

Benefits of Used Industrial Generators

- Significant Cost Savings: A more budget-friendly option without sacrificing reliability.

- Faster Availability: Often quicker to acquire and install than new, custom-ordered units.

- Sustainability: A greener choice by extending the lifespan of existing equipment.

- Why Buy Used from Generator Source: We specialize in high-quality used generators. Our rigorous inspection and refurbishment process ensures every unit meets strict performance standards. We thoroughly test, service, and, if necessary, repair units to deliver dependable power.

Need help finding a generator?

Not sure where to start with your power system? Our team is here to help. Generator projects involve many factors – from sizing and site preparation to compliance – so it’s wise to consult with our experts (and your electrical engineers) early in the process. We can assist in selecting the optimal unit or paralleling setup and ensure all technical requirements are met before purchase and installation.

Our Values

Our mission is to provide reliable power solutions that empower businesses across industries, ensuring seamless operations with unmatched expertise and quality.

Since our founding over four decades ago, Generator Source has grown to become the country’s largest buyer and seller of commercial generators, with branches and service teams ready to deliver power solutions nationwide.

People First

We prioritize relationships, building trust and respect in every customer and team interaction.

Quality of work

We hold ourselves to the highest standards, delivering reliable power solutions backed by rigorous testing.

Dedication

We go the extra mile to support our customers and stand behind every generator we service and sell.

Expertise

With 50 years of industry experience, our team brings unmatched knowledge to every project.

Still have questions or looking for more information?

Generator Source specializes in low-hour, used, new, and surplus generator sets. We have a wide variety of generator sizes and models to fit any project. We are not a broker, we own what we sell.

Call us today (877-866-6895) or click Contact Us to be connected with one of our experienced sales reps.

We have 350+ generators in stock and ready to ship!