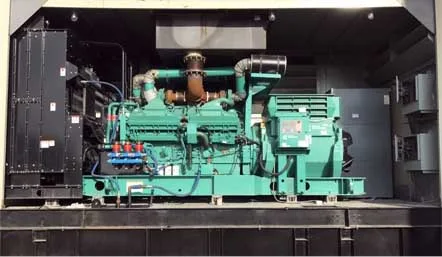

In the world of generators, a silencer performs the same function for combustion engines as a muffler does for engines in automotive and construction applications. Both reduce noise and exhaust emissions produced during combustion.

Types of Generator Silencers

Reactive Silencers

- Internal construction consists of up to three chambers connected by a tube.

- Exhaust noise bounces between the chambers, reducing output noise.

- Best for low to mid-frequency noise reduction.

Absorptive Silencers

- Internal construction consists of fiberglass or E-glass insulation.

- Dampens exhaust noise as it flows through the insulation.

- Ideal for reducing high-frequency sound waves.

Combination Silencers

- Combines reactive and absorptive silencer designs.

- Absorption material is fitted into the reactive silencer’s chamber design.

- Effective for reducing noise across all frequency ranges.

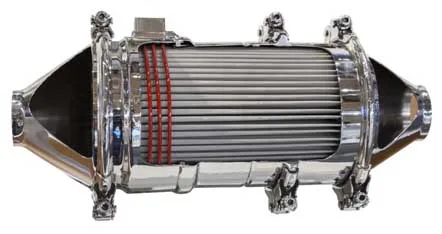

Cylindrical Silencers

Cylindrical silencers are among the first shapes developed and can be constructed using any of the three basic designs. They are suitable for indoor and outdoor applications, can be mounted horizontally or vertically, and are considered one of the most economical options.

Low Profile Silencers

Low-profile silencers come in various shapes, such as rectangular, oval, and round. The shape depends on the space available, making them ideal for generators in sound-attenuated enclosures. These silencers must meet National Fire Protection Association (NFPA) guidelines.

Spark-Arrested Silencers

- Modified reactor design captures carbon sparks in a collection box.

- Used in combustible environments.

- Collection boxes must be cleaned regularly as part of maintenance.

Heat Recovery Silencers

- Utilize exhaust gases (up to 1400°F) to supply heat to external systems.

- Commonly used for heating water or other heat-requiring applications.

Emission Control Silencers

Combustion gases include harmful substances regulated by the Environmental Protection Agency (EPA). Emission control silencers address these concerns:

Catalytic Converters

- Constructed with a honeycomb grid design.

- Positioned after the exhaust manifold for optimal temperature and efficiency.

- Combined with silencers in some designs to meet Tier IV regulations.

Particulate Matter Filters

- Made of ceramic material to reduce soot content.

- Lean burn engines may use additives to further reduce emissions.

Note: Advanced emission systems are not required for emergency or backup generators.

Sound Ratings for Generator Silencers

Sound intensity from an exhaust system is measured in Decibels (dB). The Electrical Generating Systems Association (EGSA) developed a consistent rating guide for silencers.

Common Silencer Grades

- Industrial Grade: Reduces exhaust noise by 15–20 dBA.

- Residential Grade: Reduces exhaust noise by 20–25 dBA.

- Critical Grade: Reduces exhaust noise by 25–32 dBA.

- Super Critical Grade: Reduces exhaust noise by 30–38 dBA.

- Hospital Grade: Reduces exhaust noise by 35–42 dBA.

- Hospital Plus Grade: Reduces exhaust noise by 35–50 dBA.

- Extreme Grade: Reduces exhaust noise by 40–55 dBA.

- Super Extreme Grade: Reduces exhaust noise by 45–60 dBA.

Not all silencers or styles are available in every grade. Style production cost and physical capabilities dictate availability.

Additional Resources

The EGSA provides a useful PDF guide on Rating Generator Silencers for further information.