Controlling our Machines

Any complex piece of machinery requires a user interface to enable the user to monitor its operations, check for efficient functioning, and intervene when required. Machines overheat, slow down, speed up, or generally vary in their performance based on numerous factors such as fatigue, weather conditions, and the wear and tear of components and parts.

In electrical machines, like generators, these varying changes constitute an electrical signal. Additional information about generators and their components can also be found in the article, How Generators Work. These signals can be intelligently processed to control the performance of the machine. A lot of machines in urban environments (such as signal lights and automatic doors) are completely self-managed due to such controllers. They have sensors that can detect changes in physical attributes like heat and speed and generate signals accordingly. Modern generators also have similar sensors to detect changes in all kinds of various parameters. These can be used to control the generator through a control panel.

The Control Panel – What is it?

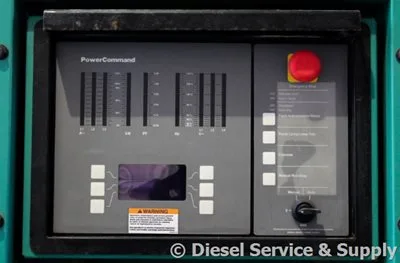

Visually, a control panel is a set of displays that indicate the measurement of various parameters like voltage, current, and frequency through gauges and meters. These meters and gauges are set in a metallic body, usually corrosion-proof, to protect from the effect of rain or snow.

- Small Generators: Control panels may be set up on the body of the generator itself and typically have vibration-proof pads to isolate the control panel from shocks.

- Larger Industrial Generators: Control panels can be completely separate from the generator and are large enough to stand on their own. These units may be shelf-mounted or wall-mounted inside enclosures for applications like data centers.

Control panels are usually fitted with buttons or switches that help operate the generator, such as a switch-off button or turn-on key. The switches and gauges are grouped based on functionality, making the panel friendly and safe for use.

How Does It Work?

The control panel is an increasingly complex piece of electronics, equipped with a microprocessor that manipulates sensor input to help give feedback to the machine for self-management.

Sensor Feedback and Regulation

- Sensors detect changes in parameters such as temperature, speed, and oil pressure.

- The microprocessor in the control panel interprets these inputs and regulates performance.

- In extreme conditions, such as overheating or low oil pressure, the control panel may shut down the generator to prevent damage.

Integration with Automatic Transfer Switch (ATS)

Control panels can combine with an ATS to maintain electrical power continuity:

- Detecting Power Outages: The ATS senses grid failure and signals the control panel to start the generator.

- Starting the Generator: Depending on the generator type, the control panel activates components like glow plugs and the automatic starter.

- Seamless Power Transition: Once the generator reaches optimum speed, the ATS switches to generator power, ensuring uninterrupted operations.

This functionality is invaluable in both residential and industrial settings, especially during emergencies or bad weather.

Custom Control Panels

Control panel units are typically designed by the generator manufacturer and embedded with the product. However, custom panels can be created to meet specific requirements.

Standard Features

- Continuous digital readouts

- Large-character LCD screens

- Displays for running time, oil pressure, and water temperature

- Wiring harnesses

- Remote and local start/stop capabilities

Customization Options

- Specific parameters for monitoring

- Preference for LCD indicators over analog meters

- Automation requirements

- Additional gauges and meters

Custom panels are popular for both industrial and residential applications. When evaluating a generator, always review the control panel’s features to ensure it meets your specific needs. Additional insights can be found in the article, Tips When Buying a Generator.