Generator Preventative Maintenance Service

Customized Generator Maintenance Plans for Industrial and Commercial Systems

Your generator is only reliable if it’s maintained regularly. Preventative maintenance is essential to ensure your system performs when you need it most. At Generator Source, we offer structured generator preventative maintenance service plans tailored to your operation schedule, system size, and compliance requirements. Whether your generator runs weekly or only during emergencies, our certified technicians provide consistent, thorough service to extend equipment life and prevent costly failures. With over 50 years of experience and service teams across Colorado, Florida, and Texas, we help organizations stay powered and prepared year-round.

What Is Generator Preventative Maintenance?

Preventative maintenance is a scheduled service program designed to keep your generator running at optimal performance. Rather than waiting for problems to arise, this approach identifies potential issues before they lead to system failure.

Our Preventative Maintenance Programs

PM1 Package – Minor Services

This is a 30-point inspection that includes a complete operational check of your generator system. Coolant and oil samples are taken and sent for lab analysis to identify signs of wear or contamination. This service remains the same whether performed monthly, quarterly, or semi-annually.

PM2 Package – Major Services

This is a full annual service that includes all items from the Minor (PM1) inspection, plus an oil and filter change. We also pair this visit with a load bank test to verify that the generator can carry its rated load without issue. The PM2 service ensures your generator is both mechanically and electrically ready for operation.

Our PM programs are tailored for diesel and natural gas generators from 20kW to 4000kW.

Our services include

- 30-point visual and operational inspection Oil and coolant sampling and analysis

- Oil and filter changes (during PM2)

- Battery testing and charging system checks

- Fuel system inspection and filter replacement

- Exhaust and air intake evaluation

- Inspection of belts, hoses, and gaskets

- Load bank testing and documentation

- Maintenance logs and compliance reporting

Why Preventative Maintenance Matters

A backup generator is only as dependable as its last service.

Without preventative care, your system is vulnerable to mechanical wear, fluid contamination, sensor failure, and electrical degradation, often without visible warning signs.

Many failures occur because generators are not tested or inspected until they are already needed. Preventative maintenance ensures your unit is never out of service when it matters most.

- Reliable generator startup during emergencies

- Early detection of engine or alternator problems

- Extended generator lifespan and lower lifetime cost

- Compliance with insurance, NFPA 110, and local regulations

- Peace of mind for facilities that depend on continuous uptime

Generator Preventative Maintenance Checklist

PM1 – Minor Maintenance Checklist

- Perform 30-point visual and operational inspection

- Record generator hours and check service logs

- Inspect coolant levels, pressure, and condition

- Draw coolant and oil samples for lab analysis Inspect battery condition, terminals, and voltage

- Check charger and alternator output

- Test and inspect control panel and alarms

- Inspect air intake and exhaust system for blockages Inspect belts, hoses, gaskets, and mounting points

- Confirm fuel level, inspect lines, and check for leaks

- Run generator and monitor startup and idle behavior

- Check oil level, appearance, and pressure readings

- Review recent fault codes and diagnostic alerts

PM2 – Major Maintenance Checklist

Includes all PM1 items, plus:

- Drain and replace engine oil

- Replace oil filter(s)

- Replace fuel filter(s) as needed

- Inspect and clean air filter(s)

- Perform full load bank test

- Verify voltage and frequency under load

- Document load bank test results and generator response

- Reset service intervals and confirm sensor calibrations

Brands We Service

Industries We Serve

Healthcare

We help hospitals, clinics, and care facilities meet NFPA 110 standards through scheduled inspections, load testing, and full documentation of every service visit.

Manufacturering / Warehouse

Preventative maintenance reduces unplanned shutdowns and protects critical equipment during outages. We help factories maintain uptime with routine generator care.

Commercial Real Estate

We maintain generators for office buildings, apartments, and shopping centers, ensuring HVAC, elevators, and security systems are protected during grid failures.

Farm and processing facilities depend on generators to power irrigation, storage refrigeration, and operations during peak seasons. We keep their systems tuned and ready.

Data Centers

From telecom towers to server rooms, our PM services support continuous uptime and protect data from power-related disruptions.

Utilities

Generators at water treatment plants, lift stations, and municipal facilities must perform without fail. Our maintenance programs support power reliability across public infrastructure.

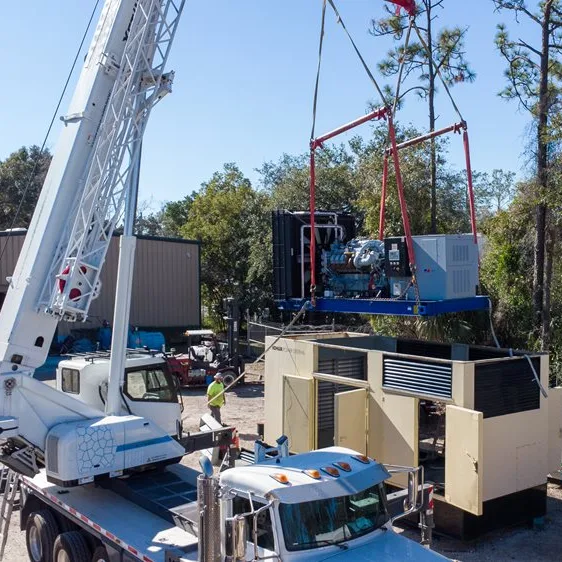

In-Shop and Field Generator Maintenance

Our team performs preventative maintenance both in our service centers and on location. Each visit includes detailed inspection reports, fluid analysis results, and service recommendations. Mobile teams are available for scheduled maintenance and emergency visits throughout the region.

Our Values

Our mission is to provide reliable power solutions that empower businesses across industries, ensuring seamless operations with unmatched expertise and quality.

Since our founding over four decades ago, Generator Source has grown to become the country’s largest buyer and seller of commercial generators, with branches and service teams ready to deliver power solutions nationwide.

People First

We prioritize relationships, building trust and respect in every customer and team interaction.

Quality of work

We hold ourselves to the highest standards, delivering reliable power solutions backed by rigorous testing.

Dedication

We go the extra mile to support our customers and stand behind every generator we service and sell.

Expertise

With 50 years of industry experience, our team brings unmatched knowledge to every project.

Frequently Asked Questions About Generator Preventative Maintenance

What is generator preventative maintenance?

Preventative maintenance is a scheduled service program designed to keep your generator running at optimal performance. It identifies potential issues before they lead to system failure, rather than waiting for problems to arise.

Why is preventative maintenance important for my generator?

A backup generator is only as dependable as its last service. Without preventative care, your system is vulnerable to mechanical wear, fluid contamination, sensor failure, and electrical degradation, often without visible warning signs. Routine maintenance ensures reliable startup during emergencies, early detection of problems, extended generator lifespan, and compliance with regulations.

What’s the difference between PM1 and PM2 services?

PM1 (Minor Service) is a 30-point inspection that includes a complete operational check, along with coolant and oil samples sent for lab analysis. This service is performed monthly, quarterly, or semi-annually. PM2 (Major Service) is an annual service that includes all items from the PM1 inspection, plus an oil and filter change, and a load bank test to verify the generator can carry its rated load.

What types of generators do you service?

We tailor our PM programs for diesel and natural gas generators ranging from 20kW to 4000kW. We service all major brands, including Caterpillar (CAT), Cummins, Kohler, Generac, MTU/Detroit Diesel, Perkins, Mitsubishi, John Deere, Volvo Penta, and Isuzu. Our service covers both modern and legacy generator systems, including custom installations and transfer switch integration.

What does a typical maintenance visit include?

Each preventative maintenance visit includes a structured checklist to ensure every critical component is inspected, tested, and documented. This involves visual and operational inspections , fluid level and quality checks (oil, coolant, fuel) , battery testing , inspection of belts, hoses, and gaskets , and system testing. PM2 visits also include oil and filter changes and a full load bank test. Every service includes a full maintenance report, inspection results, and recommendations.

What is a load bank test, and why is it important?

A load bank test verifies that the generator can carry its rated load without issue. It’s crucial for ensuring your generator is both mechanically and electrically ready for operation and is included in our annual PM2 service.

Are your technicians certified?

Yes, all services are performed by EGSA-certified technicians using best-in-class diagnostic tools and maintenance procedures.

Where do you offer generator maintenance services?

We offer both in-shop and field generator maintenance. Our fully equipped facilities are located in Brighton, Colorado; Jacksonville, Florida; Pensacola, Florida; and Austin, Texas. Mobile teams are available for scheduled maintenance and emergency visits throughout the region.

Which industries do you support with generator maintenance?

We support a wide range of industries including Healthcare and Life Safety , Manufacturing and Production , Utilities and Public Works , Telecommunications and Data Centers , Commercial Property Management , and Agriculture and Food Storage.

Still have questions or looking for more information?

Generator Source specializes in low-hour, used, new, and surplus generator sets. We have a wide variety of generator sizes and models to fit any project. We are not a broker, we own what we sell.

Call us today (877-866-6895) or click Contact Us to be connected with one of our experienced sales reps.

We have 350+ generators in stock and ready to ship!