System Function

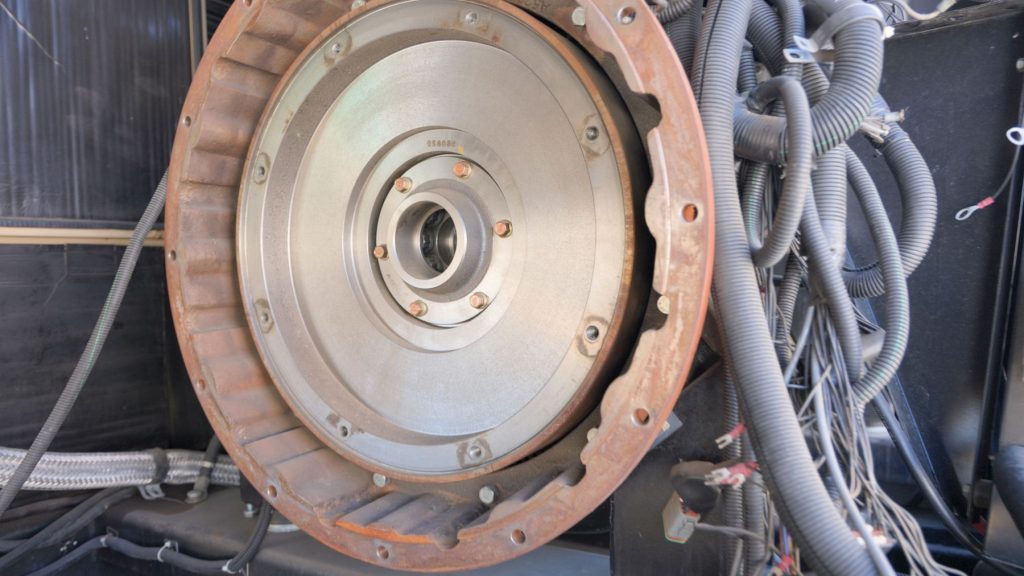

Bearings support rotating components like the alternator, fan drive and accessory pulleys so they spin smoothly under load. Good bearings keep friction low, reduce heat and prevent vibration. As bearings wear, they develop play and produce noise, heat and vibration that spreads into mounts and housings.

- Load Support: Bearings handle radial and axial forces from belt tension, component weight, and rotational forces while maintaining precise alignment under continuous operation.

- Friction Reduction: The bearing rolling elements and lubrication system minimize friction that would otherwise generate excessive heat and accelerate wear of rotating components.

That vibration can loosen hardware, damage seals and accelerate wear in connected components. If a bearing fails fully, it can seize and cause immediate shutdown or serious mechanical damage.

Bearing maintenance and inspection video

Maintenance Schedule

How often should it be inspected?

How often should bearings be replaced?

Bearings are checked for noise, free play, temperature and lubrication condition every quarter during PM1 inspections—not just left alone until they fail. We use vibration analysis and thermal imaging to detect early bearing degradation before catastrophic failure occurs.

Environmental Considerations: Bearings in dusty environments require more frequent inspection as contamination accelerates wear. Humid coastal environments cause moisture intrusion that degrades bearing lubricant and promotes corrosion. High ambient temperatures accelerate lubricant breakdown requiring more frequent bearing inspection and potential re-greasing.

How you can tell it is acting up

- High-Pitched Squealing or Grinding: Bearing noise that increases with engine RPM indicating worn rolling elements or insufficient lubrication.

- Excessive Component Heat: Bearings running significantly hotter than surrounding components revealing increased friction from wear or lubrication failure.

- Visible Play in Pulleys: Alternator or accessory pulley rocks or wobbles when pushed by hand indicating bearing wear has created excessive clearance.

- Belt Wear or Tracking Issues: Belts wearing unevenly or walking off pulleys suggesting bearing misalignment from excessive play.

- Vibration in Engine: Increased vibration felt throughout the generator as worn bearings transmit oscillating forces through mounts and housing.

Most asked question

“Can I just add grease to a noisy bearing to quiet it down?”

No. Once a bearing develops noise, internal damage has already occurred. Adding grease might temporarily reduce noise but cannot repair worn rolling elements or damaged races. The bearing will continue deteriorating and will eventually seize causing catastrophic failure of the alternator, fan, or accessory it supports. Noisy bearings require immediate replacement. Attempting to extend bearing life with additional grease only delays inevitable failure and risks expensive secondary damage to connected components during an emergency run.

Frequently Asked Questions

How long do generator bearings typically last?

Bearing life varies dramatically based on operating conditions. In clean well maintained environments with proper lubrication alternator and fan bearings typically last 15,000 to 20,000 hours or 10 to 15 years. However bearings in dusty environments high ambient temperatures or with inadequate lubrication may fail in 5,000 to 8,000 hours. This is why quarterly vibration analysis during PM1 inspections is critical to detect wear before failure occurs.

What causes premature bearing failure?

Contamination is the primary killer. Dust and dirt act as abrasives between rolling elements and races causing rapid wear. Moisture intrusion degrades lubricant and causes corrosion. Improper belt tension creates excessive radial loads that overstress bearings. Inadequate lubrication or wrong lubricant type causes metal to metal contact and heat buildup. Vibration from engine imbalance or misalignment accelerates fatigue failure of bearing components.

Can bearings be repaired or must they be replaced?

Bearings cannot be repaired. Once rolling elements or races show wear pitting or damage the bearing must be replaced. Attempting to reuse worn bearings even after cleaning and re-greasing results in rapid failure and potential damage to expensive components like alternators. Quality bearings are relatively inexpensive compared to the alternator or fan assembly they support making replacement the only sensible option when wear is detected.

Should all bearings be replaced at the same time?

Not necessarily. Replace bearings based on condition not age. During quarterly PM1 inspections we evaluate each bearing individually through vibration analysis thermal imaging and physical inspection. Bearings showing elevated vibration increased temperature or audible noise should be replaced immediately. Bearings operating normally can remain in service. However when replacing an alternator it makes economic sense to replace its bearings preventively since the component is already removed for service.

Schedule Service

Generator Source services every make and model of commercial and industrial generators from 20kW to 4000kW. Our EGSA-certified technicians bring 50+ years of experience, and we are the largest reseller of new and used commercial generators in the country.

Call 877-866-6895 to speak with a specialist today!

Our Techs are EGSA Certified

Our certified EGSA technicians deliver exceptional, hands-on expertise that our customers rely on.

| Maintenance Item |

|---|

| ▼ 31 Point Inspection Items / PM1 |

| Air Inlet System & Air Filter |

| Alternator |

| Barrel Insulation |

| Batteries |

| Battery Charger |

| Bearing(s) |

| Belts, Hoses & Connections |

| Block Heater |

| Breaker(s) |

| Collect Oil & Coolant Samples |

| Coolant & Coolant Filter(s) |

| Crankcase Breather(s) |

| Exhaust Manifold |

| Fan and Fan Drive |

| Fuel Filters – Prim/Sec |

| Fuel Lines & Connections |

| Fuel Tank & Rack |

| Gauges |

| Governor and controls |

| Jacket Water Heater |

| Oil & Oil Filter(s) |

| Radiator |

| Remote Annunciators/Alarms |

| Safety Controls |

| Starter |

| Turbocharger(s) |

| Valves and Valve Rotators |

| Vibration Isolators |

| Voltage |

| Water Pump |

| Water Separator |