System Function

Hoses and connections carry coolant, fuel and air throughout the generator. They must stay sealed and properly routed. Good hose condition prevents leaks, air intrusion and pressure loss that can take the generator offline unexpectedly. As hoses age, they harden, crack, and weaken internally, even if they look fine on the outside.

- Pressure Containment: Hoses and connections must withstand coolant system pressure up to 15 PSI, fuel pump pressure, and intake vacuum without leaking or collapsing under temperature extremes.

- Proper Routing: Correct hose routing prevents chafing against sharp edges, heat exposure from exhaust components, and stress from vibration that causes premature failure.

Loose clamps or worn fittings can cause small leaks to grow under heat and pressure during a run. These failures often show up as coolant loss, fuel odor, overheating, or hard starting.

Hoses and connections inspection video

Maintenance Schedule

How often should it be inspected?

How often should hoses be replaced?

Hoses and connections are inspected for softness, cracking, clamp tension, routing, rub points, and seepage residue every quarter during PM1 inspections—not just replaced by time alone. We check for internal deterioration that is not visible externally using squeeze tests and pressure testing.

Environmental Considerations: Hoses exposed to high ambient temperatures or engine heat deteriorate faster as rubber compounds break down. Ozone exposure in urban or industrial environments accelerates surface cracking. Fuel and oil exposure degrades hose materials from the inside. Generators operating in environments with temperature extremes experience accelerated hose hardening and brittleness.

How you can tell it is acting up

- Visible Coolant Leaks or Stains: Green, orange or pink fluid puddles under generator or staining on hoses and connections indicating coolant seepage.

- Fuel Odor Near Generator: Strong fuel smell suggesting fuel line leakage or loose connection allowing vapor escape.

- Overheating Alarms: Engine temperature rising above normal despite adequate coolant level indicating restricted coolant flow from collapsed hose.

- Hard Starting or Stalling: Air intrusion into fuel system from cracked fuel lines causing inconsistent fuel delivery and combustion problems.

- Cracks in Hose Surface: Visible surface cracks in rubber indicating advanced age and internal deterioration even if hose has not yet failed.

Most asked question

“The hoses look fine externally—do they really need replacement?”

Yes, when testing indicates internal deterioration. Rubber hoses age from the inside out. Heat cycles cause internal rubber to separate from reinforcement layers creating soft spots and weak areas invisible from outside. A hose that appears perfect externally can fail catastrophically under pressure during an emergency run. We perform squeeze tests to detect soft spots and inspect for micro-cracking that indicates the rubber compound has deteriorated beyond safe use. When hoses reach 5 to 7 years of age or show any signs of deterioration during testing, replacement prevents emergency failures that could disable your generator when you need it most.

Frequently Asked Questions

How often should hoses be replaced?

Replace hoses based on condition not just age. During quarterly PM1 inspections we evaluate hoses for hardening surface cracking internal soft spots and proper routing. Hoses typically last 5 to 7 years in normal conditions but may require replacement sooner in harsh environments high heat ozone exposure or frequent operation. Coolant hoses under pressure are particularly critical. When any hose shows deterioration all hoses of similar age should be inspected carefully as they likely experienced similar conditions.

What causes premature hose failure?

Heat is the primary enemy. Hoses exposed to exhaust components or high ambient temperatures deteriorate rapidly as rubber compounds break down. Improper routing that allows hoses to contact sharp edges causes chafing and leaks. Over-tightened clamps crush hose material creating weak spots. Chemical exposure from fuel oil or incompatible coolant degrades rubber from inside. Ozone exposure accelerates surface cracking. Vibration from loose mounting causes fatigue failure at connection points.

Can I use automotive hoses for my generator?

Generally no. Generator hoses must withstand longer temperature cycles and more severe duty than automotive applications. Generator coolant hoses experience extended heat soaking while running under load then cool completely during idle periods. This cycling is more severe than automotive use. Some generator applications require specific hose compounds for resistance to coolant additives or higher temperature ratings. Always use hoses meeting generator manufacturer specifications to ensure reliability and longevity.

What about belts should they be replaced with hoses?

Belts are inspected separately during PM1 inspections. We check for cracking glazing proper tension and wear. Serpentine belts typically last 3 to 5 years while V-belts may need replacement more frequently. Belt failure causes immediate loss of alternator and cooling system function leading to shutdown. When replacing belts we also inspect pulleys for wear and proper alignment to ensure new belts have maximum service life.

Schedule Service

Generator Source services every make and model of commercial and industrial generators from 20kW to 4000kW. Our EGSA-certified technicians bring 50+ years of experience, and we are the largest reseller of new and used commercial generators in the country.

Call 877-866-6895 to speak with a specialist today!

Our Techs are EGSA Certified

Our certified EGSA technicians deliver exceptional, hands-on expertise that our customers rely on.

| Maintenance Item |

|---|

| ▼ 31 Point Inspection Items / PM1 |

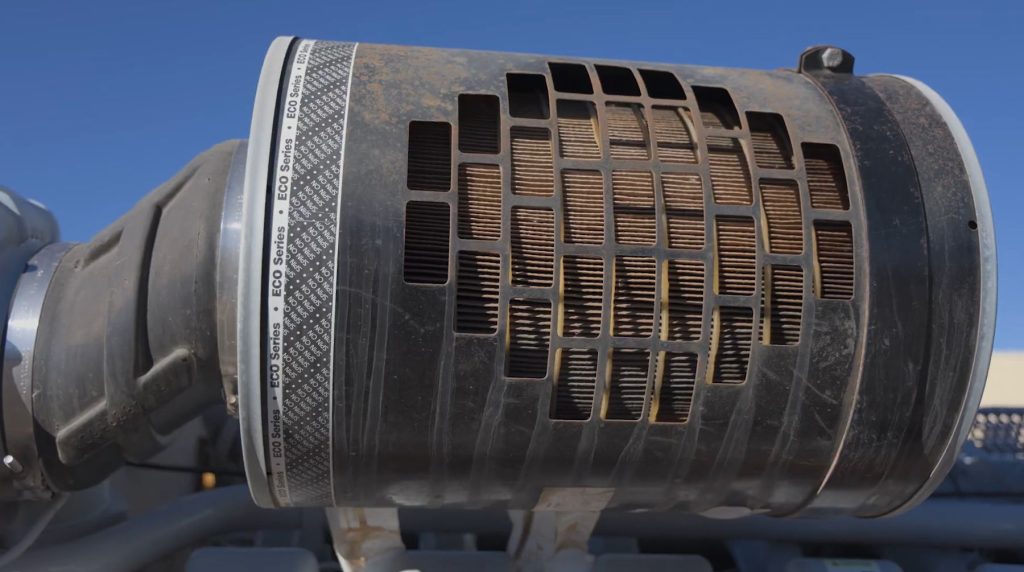

| Air Inlet System & Air Filter |

| Alternator |

| Barrel Insulation |

| Batteries |

| Battery Charger |

| Bearing(s) |

| Belts, Hoses & Connections |

| Block Heater |

| Breaker(s) |

| Collect Oil & Coolant Samples |

| Coolant & Coolant Filter(s) |

| Crankcase Breather(s) |

| Exhaust Manifold |

| Fan and Fan Drive |

| Fuel Filters – Prim/Sec |

| Fuel Lines & Connections |

| Fuel Tank & Rack |

| Gauges |

| Governor and controls |

| Jacket Water Heater |

| Oil & Oil Filter(s) |

| Radiator |

| Remote Annunciators/Alarms |

| Safety Controls |

| Starter |

| Turbocharger(s) |

| Valves and Valve Rotators |

| Vibration Isolators |

| Voltage |

| Water Pump |

| Water Separator |