System Function

Oil and coolant samples give a clear picture of internal engine health that you cannot get from a quick visual check. Lab analysis can reveal wear metals, fuel dilution, coolant intrusion, acidity, and additive breakdown while the generator is still running normally. When these values start trending the wrong way, it usually means something is developing inside the engine or cooling system before a failure shows up on the controller.

- Wear Metal Detection: Analysis identifies microscopic metal particles from bearings, cylinders and other components revealing abnormal wear rates months before mechanical failure becomes audible.

- Contamination Identification: Testing detects fuel dilution from injector problems, coolant intrusion from head gasket leaks, or dirt ingestion from air filter failures.

Ignoring early indicators can lead to low oil pressure events, overheating, injector issues, or accelerated wear that shortens engine life.

Oil and coolant sample analysis video

Maintenance Schedule

How often should oil samples be taken?

How often should coolant samples be taken?

Samples are pulled using clean methods and consistent locations, then analyzed every quarter during PM1 inspections—not just taken after a problem occurs. Trending analysis over time reveals developing issues before they become emergencies.

Environmental Considerations: Generators in dusty environments show higher silicon levels requiring more frequent sampling. High humidity may show moisture contamination. Generators with infrequent operation may show additive settling or fuel dilution from incomplete combustion.

How you can tell it is acting up

- Dark or Opaque Oil: Oil appears black or cloudy indicating contamination from soot, fuel or coolant.

- Metallic Particles in Oil: Visible metal flakes on drain plug revealing abnormal wear.

- Oil Smells Like Fuel: Strong diesel odor suggesting fuel dilution from injector problems.

- Coolant Looks Rusty: Orange or brown coolant indicating corrosion or oil contamination.

- Rapid Oil Consumption: Oil level drops significantly between services without visible leaks.

Most asked question

“The oil looks clean—do I really need lab analysis?”

Absolutely. Visual inspection cannot detect microscopic wear metals and chemical changes. Oil can appear clean while containing dangerous levels of silicon from air filter deterioration, iron from cylinder wear, or copper from bearing degradation. Fuel dilution or coolant intrusion are invisible until damage is severe. Lab analysis detects parts-per-million levels revealing problems months before catastrophic failure. The cost is minimal compared to engine repairs that could have been prevented.

Frequently Asked Questions

What metals in oil analysis indicate serious problems?

Iron indicates cylinder liner piston ring or crankshaft wear. Copper and lead point to bearing wear. Aluminum suggests piston damage. Chromium indicates piston ring wear. Silicon reveals air filter problems. Rapid increases or levels exceeding manufacturer limits indicate accelerated wear requiring investigation.

How is oil sampling performed correctly?

Sample must be taken from consistent location during normal operating temperature using clean equipment. Mid-stream sampling during oil change provides best representation. Sample bottle must be clean and properly labeled with unit identification date and hours. Send to lab promptly as some characteristics degrade during storage.

What does high fuel dilution in oil indicate?

Fuel dilution occurs when diesel enters crankcase instead of burning in cylinders. Common causes include worn or leaking injectors, incomplete combustion from short run cycles, or injector timing problems. Fuel dilution thins oil reducing its ability to protect bearings and cylinder walls. Levels above 2 to 3 percent require investigation.

How often should coolant be sampled and what are critical parameters?

Sample coolant annually during PM2 service or more frequently if contamination is suspected. Critical parameters include freeze point, pH to ensure proper corrosion inhibition typically 8 to 11, reserve alkalinity to measure remaining inhibitor life, and contamination from oil or chemicals. Coolant should be replaced when inhibitors deplete typically every 3 to 5 years.

Schedule Service

Generator Source services every make and model of commercial and industrial generators from 20kW to 4000kW. Our EGSA-certified technicians bring 50+ years of experience, and we are the largest reseller of new and used commercial generators in the country.

Call 877-866-6895 to speak with a specialist today!

Our Techs are EGSA Certified

Our certified EGSA technicians deliver exceptional, hands-on expertise that our customers rely on.

| Maintenance Item |

|---|

| ▼ 31 Point Inspection Items / PM1 |

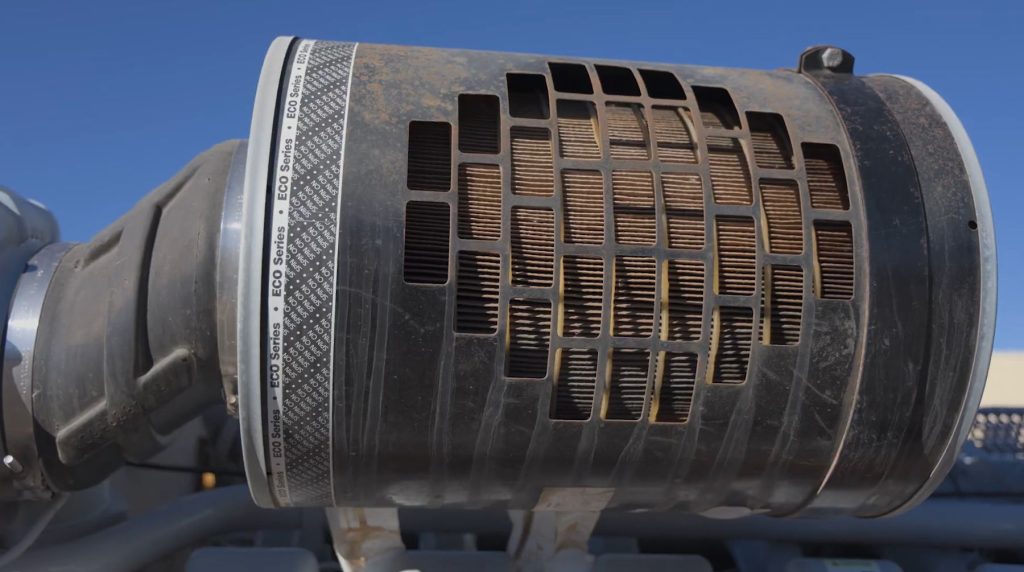

| Air Inlet System & Air Filter |

| Alternator |

| Barrel Insulation |

| Batteries |

| Battery Charger |

| Bearing(s) |

| Belts, Hoses & Connections |

| Block Heater |

| Breaker(s) |

| Collect Oil & Coolant Samples |

| Coolant & Coolant Filter(s) |

| Crankcase Breather(s) |

| Exhaust Manifold |

| Fan and Fan Drive |

| Fuel Filters – Prim/Sec |

| Fuel Lines & Connections |

| Fuel Tank & Rack |

| Gauges |

| Governor and controls |

| Jacket Water Heater |

| Oil & Oil Filter(s) |

| Radiator |

| Remote Annunciators/Alarms |

| Safety Controls |

| Starter |

| Turbocharger(s) |

| Valves and Valve Rotators |

| Vibration Isolators |

| Voltage |

| Water Pump |

| Water Separator |