System Function

The exhaust manifold collects exhaust gases from the engine and routes them into the exhaust system. It runs extremely hot and is exposed to constant heat cycling as the generator starts, runs, and cools. When the manifold cracks or leaks, hot gases escape and can overheat nearby wiring and components and carbon monoxide risk increases in enclosed areas.

- Gas Collection and Routing: The manifold gathers high temperature exhaust gases from each cylinder and directs them into a single exhaust outlet maintaining proper backpressure for engine operation.

- Heat Management: Manifold design controls exhaust gas temperature and flow velocity preventing damage to downstream components while maintaining engine efficiency and emissions compliance.

Leaks also affect engine performance and can trigger alarms due to abnormal temperatures. You may hear a ticking sound that changes as the engine warms.

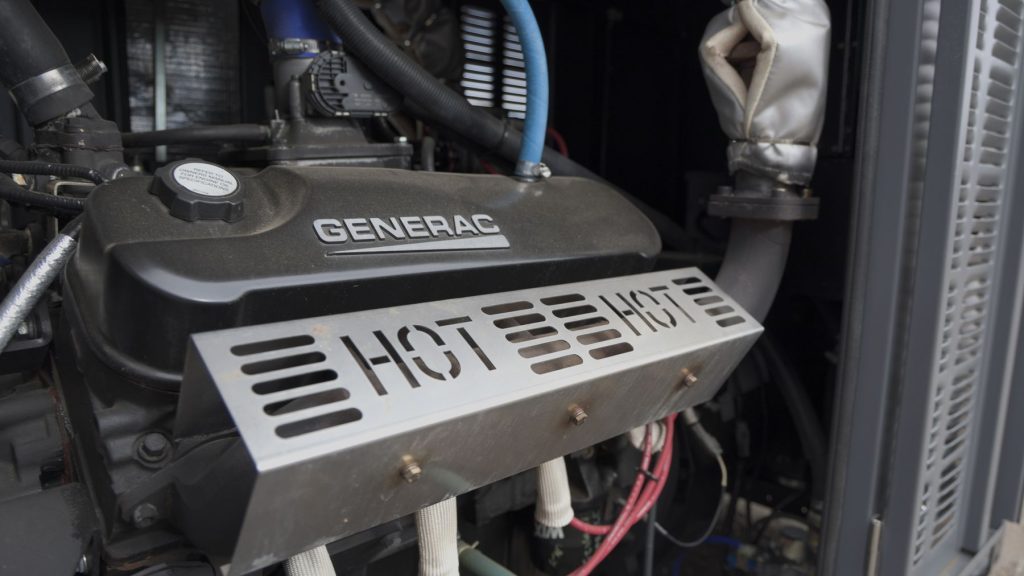

Exhaust manifold inspection video

Maintenance Schedule

How often should it be inspected?

How often should gaskets be replaced?

Exhaust manifolds are checked for cracks, soot trails, fastener integrity, and gasket sealing every quarter during PM1 inspections—not just judged by noise from a distance. Gaskets are typically replaced during major service intervals or when leaks are detected.

Environmental Considerations: Manifolds on generators experiencing frequent start-stop cycles undergo more severe thermal stress accelerating crack formation. Generators in enclosed spaces require more frequent leak inspection due to carbon monoxide hazards. Coastal environments accelerate external corrosion of manifold fasteners and mounting hardware.

How you can tell it is acting up

- Ticking or Tapping Sound: Rhythmic sound that increases with engine RPM indicating exhaust leak at manifold gasket or crack.

- Soot Stains on Manifold: Black carbon deposits on manifold surface revealing exhaust gas escaping through crack or failed gasket.

- Burnt Wire Insulation: Damaged wiring or components near manifold indicating excessive heat from escaping exhaust gases.

- Unusual Exhaust Odor: Strong exhaust smell in generator room suggesting leak allowing gases into enclosure.

- High Exhaust Temperature Alarms: Temperature sensors detecting abnormally high readings from hot spots created by manifold leaks.

Most asked question

“I hear a ticking sound but it goes away when the engine warms up—should I be concerned?”

Yes. This is a classic symptom of exhaust manifold gasket failure or developing crack. The ticking occurs because cold metal has tighter clearances allowing exhaust pressure pulses to escape. As the manifold heats and expands, metal movement temporarily reduces the leak making the noise less noticeable. However the leak still exists allowing hot exhaust gases to escape potentially damaging nearby wiring, hoses or other components. Exhaust leaks also reduce engine efficiency and create carbon monoxide hazards in enclosed spaces. Any ticking sound from the exhaust system requires immediate inspection and repair before minor gasket leak becomes major manifold crack requiring expensive replacement.

Frequently Asked Questions

What causes exhaust manifolds to crack?

Thermal cycling is the primary cause. Manifolds heat to over 1000F during operation then cool to ambient temperature creating expansion and contraction stress. Repeated cycling causes metal fatigue and eventual cracking especially at stress concentration points like bolt holes and cylinder junctions. Overtightened mounting bolts prevent proper thermal expansion creating stress. Corrosion from condensation weakens material. Cold starts create thermal shock accelerating crack formation.

Can exhaust manifold cracks be repaired?

Welding exhaust manifolds is possible but rarely provides long term solution. High temperatures and thermal cycling cause welds to crack again quickly. Cast iron manifolds are particularly difficult to weld requiring preheat and specific welding procedures. Most manifold cracks require replacement with new or remanufactured unit for reliable long term repair. Temporary sealants are ineffective at exhaust temperatures and pressures.

How often should exhaust manifold gaskets be replaced?

Replace gaskets whenever manifold is removed or when leaks develop. Gaskets are heat cycled and compressed losing their sealing ability over time. Many generators require gasket replacement during major overhauls typically every 5 to 10 years depending on operating hours. Gaskets are relatively inexpensive compared to damage from exhaust leaks making proactive replacement during scheduled maintenance economically sensible.

Are exhaust leaks dangerous in generator rooms?

Extremely. Exhaust contains carbon monoxide which is odorless colorless and deadly. Even small leaks in enclosed generator rooms can create dangerous CO concentrations. Carbon monoxide poisoning causes headache dizziness confusion and death. All generator rooms must have proper ventilation and carbon monoxide detectors. Any suspected exhaust leak requires immediate investigation and repair. Never enter generator room when alarm is active without proper breathing apparatus.

Schedule Service

Generator Source services every make and model of commercial and industrial generators from 20kW to 4000kW. Our EGSA-certified technicians bring 50+ years of experience, and we are the largest reseller of new and used commercial generators in the country.

Call 877-866-6895 to speak with a specialist today!

Our Techs are EGSA Certified

Our certified EGSA technicians deliver exceptional, hands-on expertise that our customers rely on.

| Maintenance Item |

|---|

| ▼ 31 Point Inspection Items / PM1 |

| Air Inlet System & Air Filter |

| Alternator |

| Barrel Insulation |

| Batteries |

| Battery Charger |

| Bearing(s) |

| Belts, Hoses & Connections |

| Block Heater |

| Breaker(s) |

| Collect Oil & Coolant Samples |

| Coolant & Coolant Filter(s) |

| Crankcase Breather(s) |

| Exhaust Manifold |

| Fan and Fan Drive |

| Fuel Filters – Prim/Sec |

| Fuel Lines & Connections |

| Fuel Tank & Rack |

| Gauges |

| Governor and controls |

| Jacket Water Heater |

| Oil & Oil Filter(s) |

| Radiator |

| Remote Annunciators/Alarms |

| Safety Controls |

| Starter |

| Turbocharger(s) |

| Valves and Valve Rotators |

| Vibration Isolators |

| Voltage |

| Water Pump |

| Water Separator |