System Function

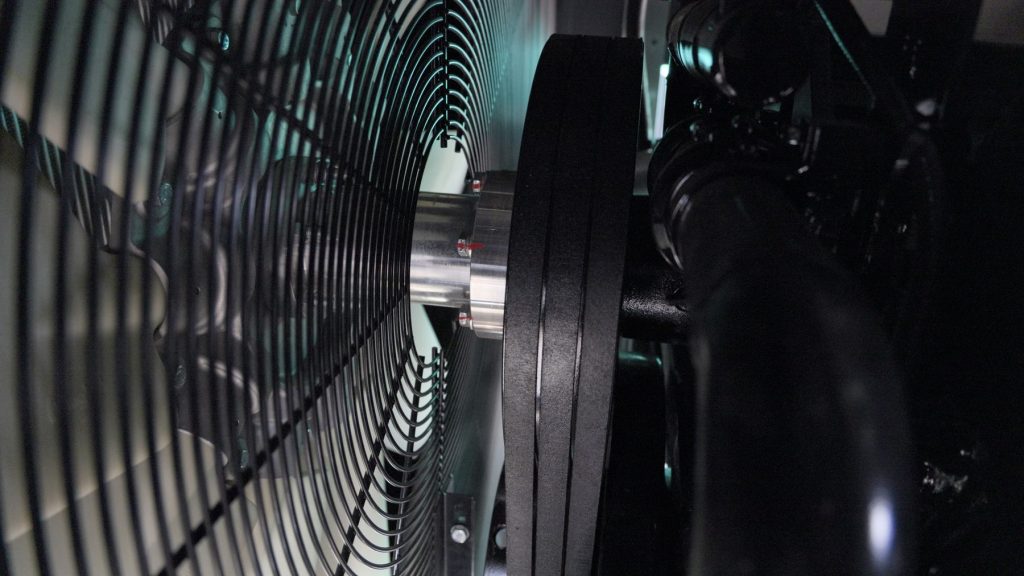

The fan and fan drive move air through the radiator to remove heat from the coolant. In a stationary generator that airflow is critical because cooling depends on consistent fan performance during a run. When the fan drive has problems, airflow drops and temperatures rise quickly even if coolant level is correct.

- Forced Air Cooling: The fan pulls ambient air through radiator fins removing heat from coolant and maintaining proper engine operating temperature under all load conditions.

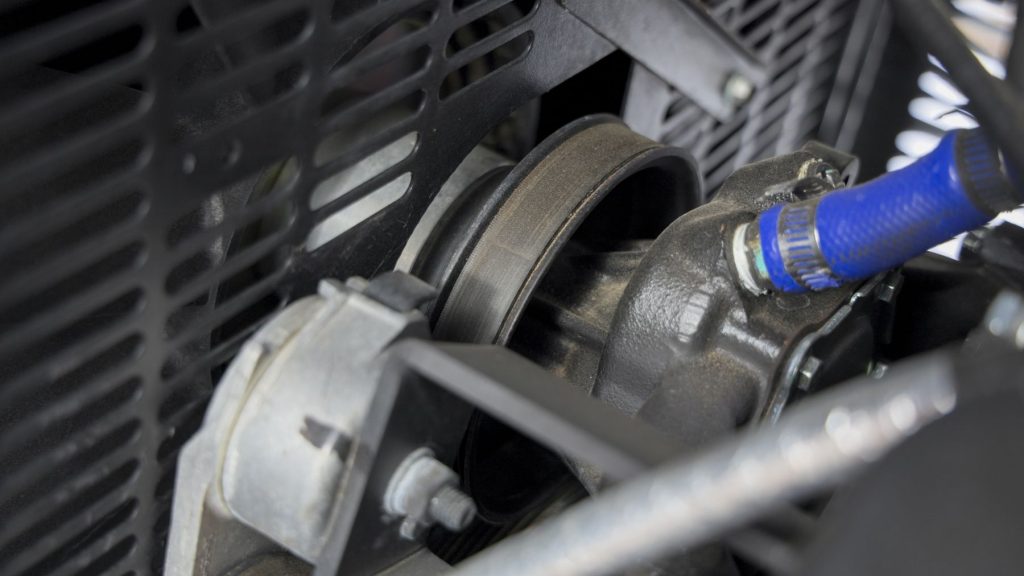

- Belt Drive System: Fan drive belts transfer power from engine crankshaft to fan maintaining proper speed ratio for adequate airflow without excessive noise or vibration.

Worn belts, damaged blades, or loose hubs can also create vibration that stresses the radiator and shroud. Overheating often appears under load or during longer run times.

Fan and fan drive maintenance video

Maintenance Schedule

How often should it be inspected?

How often should belts be replaced?

Fan systems are inspected for belt condition, blade integrity, alignment, tension, and airflow effectiveness every quarter during PM1 inspections—not just whether the fan is spinning. Belts are typically replaced every 3 to 5 years and fan bearings during major service intervals.

Environmental Considerations: Fans in dusty environments accumulate debris on blades reducing airflow efficiency. Coastal environments cause corrosion of fan hubs and mounting hardware. Generators in hot climates require more frequent fan system inspection as thermal stress accelerates belt degradation.

How you can tell it is acting up

- Overheating Under Load: Engine temperature rises above normal during loaded operation indicating insufficient airflow through radiator.

- Squealing or Chirping from Belt: High pitched noise from fan belt area indicating glazing, misalignment or improper tension.

- Visible Belt Cracking: Cracks across belt surface revealing age-related deterioration and impending failure.

- Fan Blade Damage: Bent, cracked or missing pieces of fan blades creating vibration and reduced airflow.

- Excessive Vibration: Noticeable shaking during operation suggesting fan imbalance or loose mounting hardware.

Most asked question

“The fan is spinning—does that mean the cooling system is working properly?”

Not necessarily. A spinning fan can still provide inadequate airflow due to worn belts slipping under load, damaged or missing blade sections, or incorrect belt tension. Even minor belt slippage reduces fan RPM significantly cutting airflow when you need it most under heavy load. Damaged fan blades create turbulence instead of smooth airflow through radiator. We measure actual belt tension and inspect blade condition during PM1 because visual confirmation of fan rotation tells you nothing about airflow effectiveness. Generators that run fine during no-load testing often overheat during actual power outages when inadequate fan performance is exposed under sustained load.

Frequently Asked Questions

How often should fan belts be replaced?

Replace fan belts every 3 to 5 years based on condition not just time. Belts exposed to high temperatures or frequent operation may require replacement sooner. Inspect belts quarterly for cracking glazing or fraying. Single crack across belt width indicates immediate replacement needed. Multiple cracks along length suggest advanced age. Replace belts showing any damage as belt failure during emergency operation causes immediate overheating and shutdown.

What causes premature fan belt failure?

Improper tension is primary cause. Over-tightened belts create excessive bearing load causing premature bearing failure. Under-tensioned belts slip and glaze accelerating wear. Misaligned pulleys cause uneven belt wear and premature failure. Oil or coolant contamination on belts destroys rubber compound. High ambient temperatures accelerate rubber degradation. Age-related hardening from heat cycling causes cracking even without significant operating hours.

Can I replace just one belt in a multi-belt system?

No. Replace all belts simultaneously in multi-belt systems. Belts stretch and wear at different rates. Mixing new and old belts creates uneven load distribution where new belt carries most load while old belts provide little tension. This accelerates new belt wear and allows old belts to slip. Belts are relatively inexpensive compared to labor for repeated service. Always replace complete belt sets to ensure proper load sharing and maximize service life.

Why is proper belt tension critical?

Correct tension ensures adequate power transfer without excessive bearing load. Under-tensioned belts slip reducing fan speed and airflow causing overheating. Belt slippage also generates heat glazing belt surface and accelerating wear. Over-tensioned belts create excessive radial load on bearings shortening bearing life dramatically and potentially damaging alternator or fan drive components. Use manufacturer specified tension or belt tension gauge to achieve correct tension typically measured in pounds of deflection force.

Schedule Service

Generator Source services every make and model of commercial and industrial generators from 20kW to 4000kW. Our EGSA-certified technicians bring 50+ years of experience, and we are the largest reseller of new and used commercial generators in the country.

Call 877-866-6895 to speak with a specialist today!

Our Techs are EGSA Certified

Our certified EGSA technicians deliver exceptional, hands-on expertise that our customers rely on.

| Maintenance Item |

|---|

| ▼ 31 Point Inspection Items / PM1 |

| Air Inlet System & Air Filter |

| Alternator |

| Barrel Insulation |

| Batteries |

| Battery Charger |

| Bearing(s) |

| Belts, Hoses & Connections |

| Block Heater |

| Breaker(s) |

| Collect Oil & Coolant Samples |

| Coolant & Coolant Filter(s) |

| Crankcase Breather(s) |

| Exhaust Manifold |

| Fan and Fan Drive |

| Fuel Filters – Prim/Sec |

| Fuel Lines & Connections |

| Fuel Tank & Rack |

| Gauges |

| Governor and controls |

| Jacket Water Heater |

| Oil & Oil Filter(s) |

| Radiator |

| Remote Annunciators/Alarms |

| Safety Controls |

| Starter |

| Turbocharger(s) |

| Valves and Valve Rotators |

| Vibration Isolators |

| Voltage |

| Water Pump |

| Water Separator |