System Function

Primary and secondary fuel filters remove water and fine contamination from diesel fuel before it reaches the injection system. Clean, unrestricted fuel flow is essential for stable combustion and reliable load carrying performance. As filters load up, fuel restriction increases and the engine may run fine at light load but struggle when demand rises.

- Water Separation: Primary filters incorporate water separators that remove moisture from fuel preventing injector corrosion and combustion problems that reduce power output.

- Particulate Filtration: Secondary filters capture microscopic particles protecting high-pressure injection components from abrasive wear that causes expensive fuel system failures.

Symptoms often include power drop, hard starting or shutdowns under load, especially during longer run times. Contamination that bypasses filtration also accelerates injector wear and can create expensive fuel system repairs.

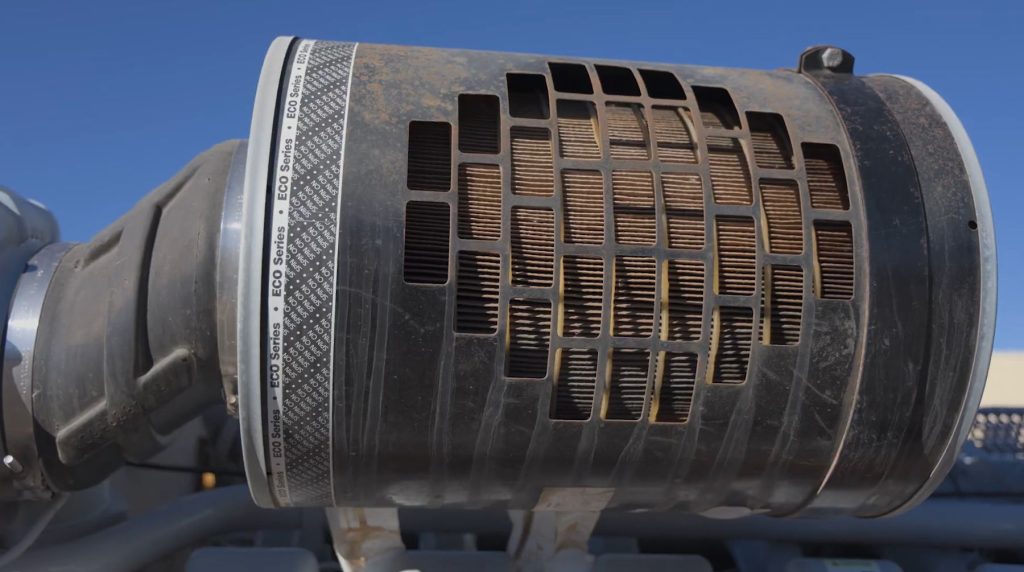

Fuel filter replacement video

Maintenance Schedule

How often should it be inspected?

How often should filters be replaced?

Fuel filters are evaluated for restriction, contamination and water presence and replaced based on condition and performance every quarter during PM1 inspections—not just hours. Filters are typically replaced annually during PM2 service or when restriction testing indicates replacement is needed.

Environmental Considerations: Generators with onsite fuel storage experience more contamination from water condensation and microbial growth requiring more frequent filter replacement. Biodiesel blends accelerate filter plugging due to higher water affinity and biological activity. Cold climates cause fuel gelling that plugs filters requiring winterized fuel or heated filter housings.

How you can tell it is acting up

- Hard Starting or Extended Cranking: Engine cranks longer than normal indicating inadequate fuel delivery from restricted filters.

- Power Loss Under Load: Generator produces rated voltage at no load but drops power when load is applied revealing fuel starvation.

- Engine Surging or Hunting: RPM fluctuates during steady load operation suggesting inconsistent fuel delivery from restricted filters.

- Fuel Filter Full of Water: Excessive water accumulation in filter bowl indicating contaminated fuel supply or tank condensation.

- Black Smoke from Exhaust: Incomplete combustion from fuel delivery problems creating excessive soot in exhaust.

Most asked question

“My fuel filters look clean—do they really need replacement?”

Visual appearance is meaningless. Fuel filter restriction occurs internally where microscopic particles accumulate in filter media invisible from outside. A filter can appear perfectly clean externally while being completely plugged internally. We measure actual fuel pressure differential across filters during PM1 using calibrated gauges. When pressure drop exceeds manufacturer specifications filters require replacement regardless of appearance or hours. Generators often run acceptably at idle or light load with restricted filters but fail when asked to carry full load during actual power outages. The cost of fuel filters is minimal compared to emergency service calls or injector replacement from contamination damage.

Frequently Asked Questions

How often should fuel filters be replaced?

Replace fuel filters annually during PM2 service as preventive maintenance regardless of condition. More frequent replacement may be required based on fuel quality tank condition and operating environment. Generators burning biodiesel blends or operating from questionable fuel sources may require filter replacement every 6 months. Always replace filters when restriction testing indicates high pressure drop or when water accumulation exceeds normal levels. Emergency replacement required if engine shows symptoms of fuel starvation.

What causes excessive water in fuel filters?

Condensation in fuel tanks is primary source. Daily temperature cycling causes moisture in tank air space to condense on cool tank walls dripping into fuel. Underground tanks in high water table areas may have groundwater intrusion through damaged seals. Biodiesel fuels naturally absorb moisture from air. Poor fuel quality from suppliers. Fuel delivery contamination. Regular fuel polishing and tank maintenance reduce water contamination requiring less frequent filter service.

Can I clean and reuse fuel filters?

No. Fuel filters are disposable and cannot be effectively cleaned. Filter media designed to trap microscopic particles cannot be back-flushed or cleaned without damaging filtration structure. Attempting to reuse filters compromises filtration allowing contamination to reach injection system. Cost of filters is trivial compared to injector replacement or fuel pump repair from contamination damage. Always install new filters meeting manufacturer specifications during service.

Why do I need both primary and secondary filters?

Each filter serves different purpose in staged filtration. Primary filter incorporates water separator removing bulk water and larger particles from fuel. Secondary filter provides fine filtration capturing microscopic particles that would damage high-pressure injection components. Two stage filtration extends secondary filter life and provides redundancy if primary filter develops leak or bypass condition. Never eliminate either filter stage as contamination reaching injection system causes catastrophic expensive damage.

Schedule Service

Generator Source services every make and model of commercial and industrial generators from 20kW to 4000kW. Our EGSA-certified technicians bring 50+ years of experience, and we are the largest reseller of new and used commercial generators in the country.

Call 877-866-6895 to speak with a specialist today!

Our Techs are EGSA Certified

Our certified EGSA technicians deliver exceptional, hands-on expertise that our customers rely on.

| Maintenance Item |

|---|

| ▼ 31 Point Inspection Items / PM1 |

| Air Inlet System & Air Filter |

| Alternator |

| Barrel Insulation |

| Batteries |

| Battery Charger |

| Bearing(s) |

| Belts, Hoses & Connections |

| Block Heater |

| Breaker(s) |

| Collect Oil & Coolant Samples |

| Coolant & Coolant Filter(s) |

| Crankcase Breather(s) |

| Exhaust Manifold |

| Fan and Fan Drive |

| Fuel Filters – Prim/Sec |

| Fuel Lines & Connections |

| Fuel Tank & Rack |

| Gauges |

| Governor and controls |

| Jacket Water Heater |

| Oil & Oil Filter(s) |

| Radiator |

| Remote Annunciators/Alarms |

| Safety Controls |

| Starter |

| Turbocharger(s) |

| Valves and Valve Rotators |

| Vibration Isolators |

| Voltage |

| Water Pump |

| Water Separator |