System Function

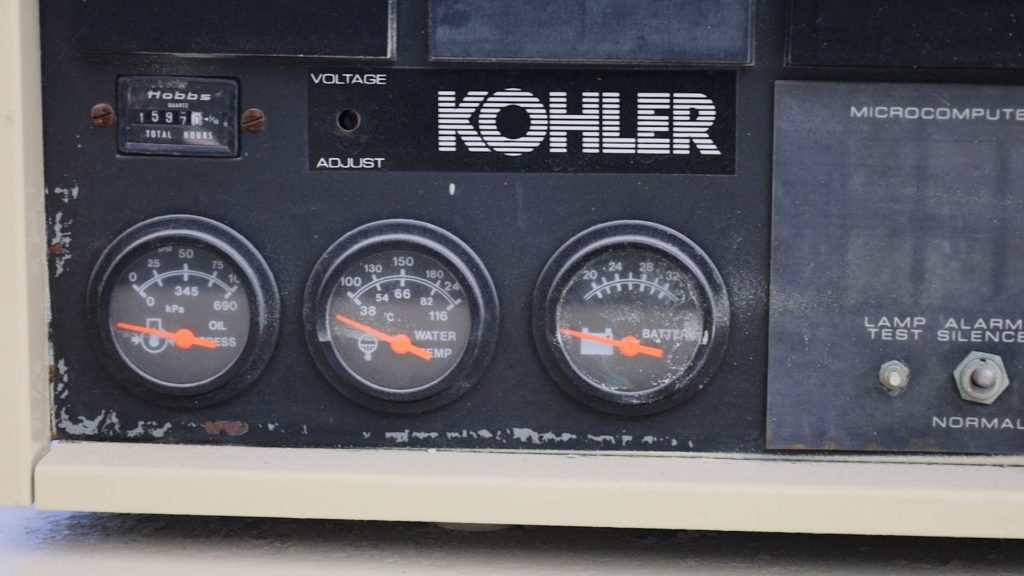

Gauges and displays report key operating values like oil pressure, coolant temperature, voltage, frequency, and battery charging. Accurate readings help confirm the generator is running safely and producing stable power during tests and real events. When gauges drift or fail, they can hide serious issues like low oil pressure or overheating until damage occurs.

- Critical Parameter Monitoring: Gauges provide real-time indication of engine health and electrical output allowing operators to detect problems before protective shutdowns occur.

- Historical Trending: Modern digital controllers log parameter history allowing analysis of developing problems through gradual changes in temperature, pressure or electrical values over time.

Incorrect readings can also cause unnecessary alarms or shutdown decisions based on bad information. Problems may show up as stuck values, numbers that jump around, or readings that do not match actual measurements.

Gauge calibration verification video

Maintenance Schedule

How often should it be verified?

How often should sensors be replaced?

Gauges are verified during service against calibrated meters and known references every quarter during PM1 inspections—not just trusted because the screen is on. Sensors and sending units are tested for accuracy and replaced when calibration drift is detected.

Environmental Considerations: Gauges and sensors in high vibration environments may experience accelerated wear of moving components. Moisture intrusion into sensor connections creates false readings. Electromagnetic interference from nearby equipment affects analog gauge accuracy. Temperature extremes outside sensor specifications cause drift or failure.

How you can tell it is acting up

- Gauge Readings Jump Erratically: Values fluctuate wildly during steady operation indicating sensor or wiring problems.

- Stuck Readings: Gauge shows same value regardless of engine condition revealing sensor or gauge failure.

- Readings Contradict Observations: Temperature gauge shows normal but engine obviously overheating or smoking.

- Conflicting Gauge Values: Digital display and analog gauge for same parameter show different values.

- Gauge Backlighting Failed: Display dark or illegible indicating electrical problem or display component failure.

Most asked question

“My gauges all show normal readings—does that mean my generator is healthy?”

Not necessarily. Gauges can display normal values while sensors or sending units have failed. A temperature sensor with open circuit may display mid-scale reading appearing normal while engine actually overheats. Oil pressure switch can fail closed showing normal pressure with no oil pressure at all. Voltage meters can display nominal values while actual voltage is outside safe range. We verify critical gauges during PM1 using calibrated test equipment measuring actual values independently. Generators that appear healthy based on gauge readings may have serious problems revealed only through independent verification. Annual load bank testing during PM2 proves gauges respond correctly to actual operating conditions under load.

Frequently Asked Questions

How often should gauges be calibrated?

Verify gauge accuracy quarterly during PM1 inspections against calibrated reference meters. Full calibration of analog gauges typically required every 3 to 5 years or when drift is detected. Digital controller displays rarely require calibration but sensors and sending units need periodic verification. Replace sensors showing excessive drift or erratic behavior. Critical safety parameters like oil pressure and temperature require most frequent verification. Consult manufacturer recommendations for specific calibration intervals.

What causes gauge inaccuracy?

Sensor drift from age or contamination changes output signal. Corroded connections create high resistance affecting signal accuracy. Electromagnetic interference affects analog signals. Mechanical wear in sending units changes calibration. Temperature cycling degrades electronic components in sensors. Vibration damages sensor internals. Incorrect wiring or ground issues create voltage offsets. Water intrusion damages sensor electronics. Most gauge problems originate at sensor not display requiring sensor replacement rather than gauge recalibration.

Can I replace analog gauges with digital displays?

Possible but requires compatibility verification. Digital displays require specific sensor types and signal ranges. Voltage and current outputs from sensors must match display inputs. Some analog sensors use variable resistance while digital sensors provide voltage or current signals. Wiring harness modifications may be required. Display mounting and power supply must be addressed. Generator controllers often provide built-in displays eliminating separate gauge requirements. Consult manufacturer before gauge replacement to ensure proper functionality.

Why do gauges sometimes show different values than my handheld meter?

Handheld meters and installed gauges may measure at different points in system. Oil pressure varies by location in lubrication system. Voltage differs between generator output and load connection points. Temperature varies throughout coolant system. Measurement errors from meter calibration or connection points. AC voltage and frequency measurements sensitive to waveform quality and meter averaging method. Small differences are normal but large discrepancies indicate gauge calibration problems requiring investigation and correction.

Schedule Service

Generator Source services every make and model of commercial and industrial generators from 20kW to 4000kW. Our EGSA-certified technicians bring 50+ years of experience, and we are the largest reseller of new and used commercial generators in the country.

Call 877-866-6895 to speak with a specialist today!

Our Techs are EGSA Certified

Our certified EGSA technicians deliver exceptional, hands-on expertise that our customers rely on.

| Maintenance Item |

|---|

| ▼ 31 Point Inspection Items / PM1 |

| Air Inlet System & Air Filter |

| Alternator |

| Barrel Insulation |

| Batteries |

| Battery Charger |

| Bearing(s) |

| Belts, Hoses & Connections |

| Block Heater |

| Breaker(s) |

| Collect Oil & Coolant Samples |

| Coolant & Coolant Filter(s) |

| Crankcase Breather(s) |

| Exhaust Manifold |

| Fan and Fan Drive |

| Fuel Filters – Prim/Sec |

| Fuel Lines & Connections |

| Fuel Tank & Rack |

| Gauges |

| Governor and controls |

| Jacket Water Heater |

| Oil & Oil Filter(s) |

| Radiator |

| Remote Annunciators/Alarms |

| Safety Controls |

| Starter |

| Turbocharger(s) |

| Valves and Valve Rotators |

| Vibration Isolators |

| Voltage |

| Water Pump |

| Water Separator |