System Function

The governor and control system regulate engine speed so electrical frequency stays stable as loads change. The controller manages start sequences and protective shutdowns. When governor response weakens, frequency can drift during load changes or right after a transfer and power quality suffers.

- Speed Regulation: The governor adjusts fuel delivery in response to load changes maintaining constant engine RPM and therefore constant electrical frequency output.

- Load Response: Quick governor response prevents frequency droop when loads are applied allowing smooth power transfer without voltage or frequency transients.

You may see hunting, surging or lights flickering as the engine tries to hold speed under changing demand. Control issues can also show up as missed starts, nuisance alarms or shutdowns that do not match actual engine conditions.

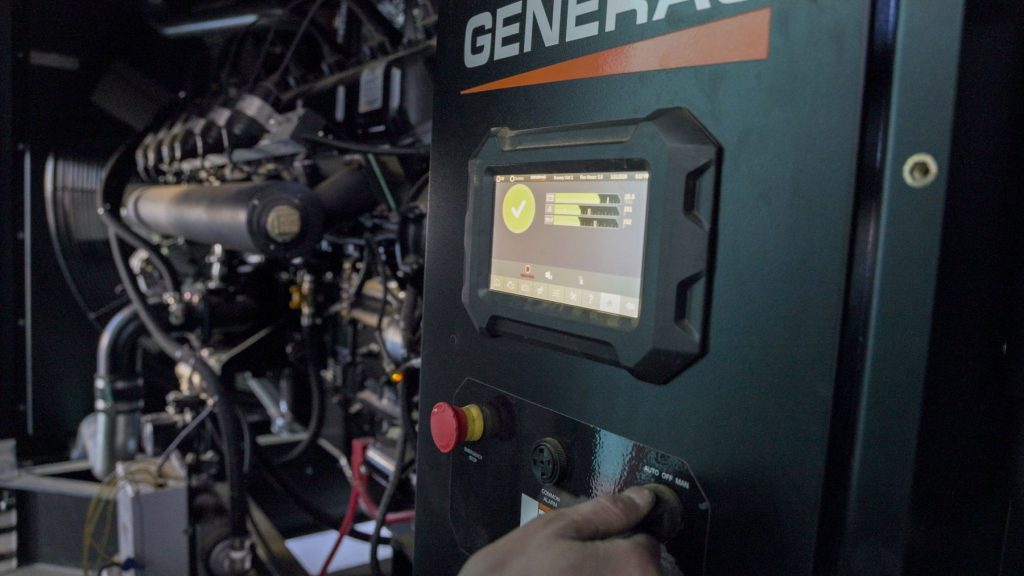

Governor maintenance video

Maintenance Schedule

How often should it be inspected?

How often should it be load tested?

Governor is checked by observing frequency stability under load, reviewing event history, confirming settings, and validating sensor input every quarter during PM1 inspections. We perform load bank testing annually during PM2 to verify proper governor response under realistic load conditions.

Environmental Considerations: Governors with mechanical linkages require more frequent adjustment as wear develops in pivot points and connections. Electronic governors in high electromagnetic interference environments may experience signal corruption. Corrosion of linkages in humid environments affects response. Temperature extremes affect oil viscosity in hydraulic governors changing response characteristics.

How you can tell it is acting up

- Frequency Hunting: Generator frequency oscillates above and below 60Hz indicating improper governor gain or linkage problems.

- Slow Load Response: Frequency drops significantly when load applied then slowly recovers revealing sluggish governor response.

- Lights Flickering During Operation: Brief voltage fluctuations as governor hunts for proper speed under changing load.

- Engine Surging at Idle: RPM fluctuates during no-load operation indicating governor instability or binding linkages.

- Inconsistent Starting: Generator starts normally sometimes but fails other times revealing governor position sensing problems.

Most asked question

“My generator maintains 60Hz at idle—does that mean the governor is working properly?”

Not necessarily. Governor performance under no load conditions reveals little about response capability under actual load changes. A generator that maintains perfect frequency at idle may have serious response problems when asked to accept load. Governor that hunts or overshoots during load transients creates voltage and frequency instability damaging sensitive equipment. Slow governor response allows excessive frequency droop during load acceptance potentially dropping below levels required for proper equipment operation. We evaluate governors during PM1 by reviewing controller event logs for frequency excursions and observing response during load changes. Annual load bank testing during PM2 proves the governor maintains stable frequency under realistic load application and rejection sequences simulating actual utility transfer conditions.

Frequently Asked Questions

What causes poor governor response?

Worn mechanical linkages create slop preventing accurate fuel position control. Binding or corroded linkages restrict movement. Electronic governor sensor failures provide incorrect speed feedback. Fuel system restrictions limit fuel delivery rate. Contaminated fuel racks or actuators create friction. Governor gain settings incorrect causing sluggish or hunting response. Hydraulic governor oil contamination affects response. Electronic actuator motors weakening with age. Loose engine mounts allow excessive movement affecting mechanical governor operation.

Can governor problems damage my equipment?

Yes. Poor frequency regulation damages motors by causing overheating from operation below rated frequency. Variable frequency drives fault or shutdown from excessive frequency variation. Computer power supplies experience reduced efficiency and potential failure. Medical equipment may provide inaccurate readings or shutdown from unstable power. In data centers frequency instability can cause server resets or data corruption. Chronic frequency problems reduce transformer efficiency and shorten motor life throughout facility. Proper governor maintenance is critical for protecting connected equipment investment.

How is governor adjusted?

Governor adjustment requires specialized knowledge and equipment. Electronic governors adjusted through controller interface using manufacturer software. Parameters include gain, droop, and damping settings affecting response characteristics. Mechanical governors require linkage adjustment and sometimes internal spring tension changes. Adjustments must be made under load conditions using precision frequency meters. Improper adjustment causes instability or poor load response. Governor adjustment should be performed only by qualified technicians with proper equipment and training.

Why does my generator frequency droop when load is applied?

Some frequency droop is normal as governor responds to load change. Excessive droop indicates sluggish governor response, fuel delivery restrictions, or incorrect droop setting. Isochronous governors should maintain frequency within 0.5Hz during load changes. Droop-configured governors intentionally allow frequency reduction for load sharing but should recover quickly. Excessive droop may indicate worn fuel injection pump, restricted fuel filters, or weak governor actuator. Load bank testing reveals actual droop characteristics allowing proper diagnosis and correction.

Schedule Service

Generator Source services every make and model of commercial and industrial generators from 20kW to 4000kW. Our EGSA-certified technicians bring 50+ years of experience, and we are the largest reseller of new and used commercial generators in the country.

Call 877-866-6895 to speak with a specialist today!

Our Techs are EGSA Certified

Our certified EGSA technicians deliver exceptional, hands-on expertise that our customers rely on.

| Maintenance Item |

|---|

| ▼ 31 Point Inspection Items / PM1 |

| Air Inlet System & Air Filter |

| Alternator |

| Barrel Insulation |

| Batteries |

| Battery Charger |

| Bearing(s) |

| Belts, Hoses & Connections |

| Block Heater |

| Breaker(s) |

| Collect Oil & Coolant Samples |

| Coolant & Coolant Filter(s) |

| Crankcase Breather(s) |

| Exhaust Manifold |

| Fan and Fan Drive |

| Fuel Filters – Prim/Sec |

| Fuel Lines & Connections |

| Fuel Tank & Rack |

| Gauges |

| Governor and controls |

| Jacket Water Heater |

| Oil & Oil Filter(s) |

| Radiator |

| Remote Annunciators/Alarms |

| Safety Controls |

| Starter |

| Turbocharger(s) |

| Valves and Valve Rotators |

| Vibration Isolators |

| Voltage |

| Water Pump |

| Water Separator |