System Function

The radiator removes heat from the coolant by transferring it to the airflow through the core. Clean fins, solid seals, and unrestricted coolant flow are required to keep temperatures stable during a run. When radiator performance drops, engine temperature rises under load and the generator may alarm or shut down to protect itself.

- Heat Dissipation: The radiator core provides large surface area for heat transfer from hot coolant to cooler ambient air flowing through fins removing thermal energy generated by combustion.

- Coolant Flow Management: Internal tubes and passages route coolant efficiently through radiator core ensuring even temperature distribution and maximum heat transfer capacity.

Blocked fins reduce airflow, internal scaling reduces heat transfer, and small leaks can introduce air and reduce cooling capacity over time. Repeated high temperature operation stresses hoses, sensors and engine components.

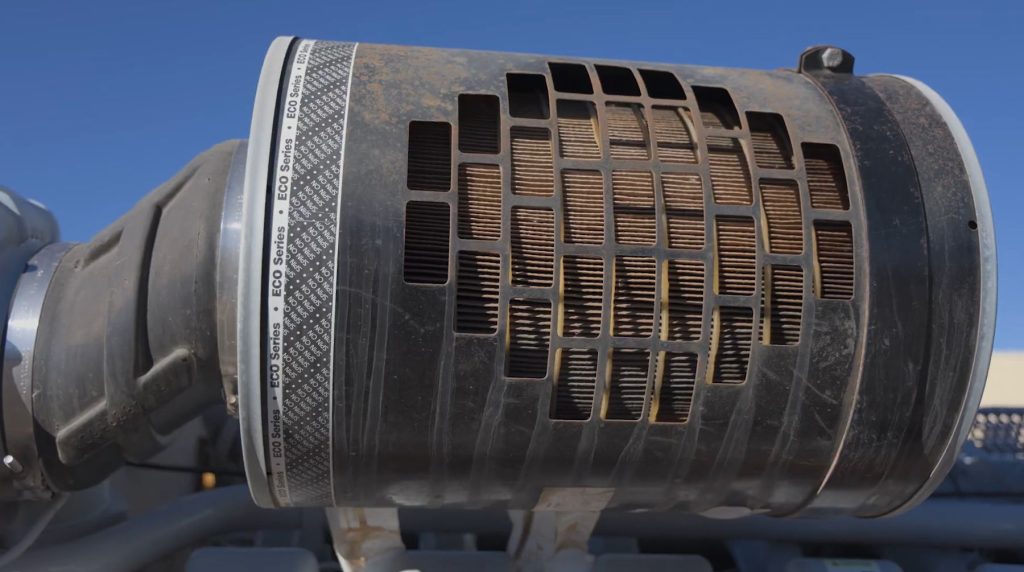

Radiator maintenance video

Maintenance Schedule

How often should it be inspected?

How often should it be pressure tested?

Radiators are inspected for airflow blockage, fin condition, leaks, coolant residue and restriction signs every quarter during PM1 inspections—not just checked for coolant level. External cleaning performed annually and pressure testing every 3 to 5 years verifies integrity.

Environmental Considerations: Radiators in dusty or agricultural environments require more frequent external cleaning as debris blocks airflow through fins. Coastal environments accelerate external corrosion of aluminum or copper-brass components. Radiators exposed to road salt or industrial chemicals experience accelerated deterioration. Generators in high ambient temperature locations operate closer to thermal limits requiring enhanced cooling system maintenance.

How you can tell it is acting up

- Overheating Under Load: Engine temperature rises above normal during loaded operation indicating insufficient heat removal capacity.

- Coolant Leaks: Visible coolant seepage from radiator core, tanks or connections revealing pressure leak or corrosion perforation.

- Restricted Airflow: Debris buildup on fins blocking air passage or damaged fins reducing effective core surface area.

- Coolant Discoloration: Rusty or contaminated coolant indicating internal corrosion or mixing of incompatible coolant types.

- Pressure Cap Failure: Cap fails to hold system pressure allowing coolant to boil at lower temperature reducing cooling effectiveness.

Most asked question

“My radiator looks clean on the outside—does it really need internal cleaning and testing?”

Yes. External appearance reveals nothing about internal condition. Scale and corrosion buildup inside radiator tubes restrict coolant flow and reduce heat transfer even with clean external fins. This internal restriction is invisible from outside but dramatically reduces cooling capacity under load. Pressure testing reveals small leaks in core or tanks that may not be visible during static inspection but will worsen under thermal stress during extended operation. Internal corrosion from improper coolant or neglected maintenance creates hot spots and eventually causes catastrophic failure during emergency runs. Professional radiator service includes chemical cleaning to remove scale, pressure testing to verify integrity, and flow testing to confirm adequate coolant circulation. This preventive maintenance is far less expensive than emergency radiator replacement or engine damage from overheating during critical operation.

Frequently Asked Questions

How often should radiators be cleaned?

Clean external surfaces annually to remove debris blocking airflow through fins. More frequent cleaning required in dusty agricultural or industrial environments. Use low pressure water or compressed air avoiding high pressure that damages fins. Chemical cleaning of internal passages recommended every 5 years to remove scale and corrosion deposits. Never use pressure washer on radiator as high pressure bends fins and damages core tubes. Proper cleaning maintains design cooling capacity preventing overheating.

What causes radiators to leak?

Corrosion from improper coolant or depleted corrosion inhibitors is primary cause. Vibration from loose mounting creates stress cracks at tube joints. Electrolytic corrosion between dissimilar metals in cooling system. External corrosion from road salt or industrial chemicals. Impact damage from debris or improper handling. Thermal cycling causes expansion and contraction stress. Age-related deterioration of gaskets and seals. Most leaks start small but worsen rapidly under pressure and temperature stress during operation.

Can radiator leaks be repaired?

Small leaks in tubes or tanks may be repairable by specialized radiator shops. Repairs typically involve soldering or epoxy sealing of leak points. However repaired radiators may develop additional leaks nearby as corrosion often affects large areas not just visible leak point. Core replacement is more reliable long term solution. Radiator stop-leak products provide only temporary fix and may clog small passages. Cost of quality repair often approaches replacement cost making new or remanufactured radiator better investment for reliability.

Why is proper coolant concentration important for radiator life?

Correct coolant mixture provides corrosion inhibitors protecting internal radiator surfaces from rust and electrolytic corrosion. Antifreeze alone without corrosion inhibitors allows rapid internal deterioration. Plain water lacks freeze protection and corrosion prevention causing severe damage. Overly concentrated coolant reduces heat transfer effectiveness. Proper 50/50 mixture provides freeze protection to minus 34F, boil protection, and corrosion inhibition. Coolant should be tested annually and replaced every 3 to 5 years to maintain protective properties.

Schedule Service

Generator Source services every make and model of commercial and industrial generators from 20kW to 4000kW. Our EGSA-certified technicians bring 50+ years of experience, and we are the largest reseller of new and used commercial generators in the country.

Call 877-866-6895 to speak with a specialist today!

Our Techs are EGSA Certified

Our certified EGSA technicians deliver exceptional, hands-on expertise that our customers rely on.

| Maintenance Item |

|---|

| ▼ 31 Point Inspection Items / PM1 |

| Air Inlet System & Air Filter |

| Alternator |

| Barrel Insulation |

| Batteries |

| Battery Charger |

| Bearing(s) |

| Belts, Hoses & Connections |

| Block Heater |

| Breaker(s) |

| Collect Oil & Coolant Samples |

| Coolant & Coolant Filter(s) |

| Crankcase Breather(s) |

| Exhaust Manifold |

| Fan and Fan Drive |

| Fuel Filters – Prim/Sec |

| Fuel Lines & Connections |

| Fuel Tank & Rack |

| Gauges |

| Governor and controls |

| Jacket Water Heater |

| Oil & Oil Filter(s) |

| Radiator |

| Remote Annunciators/Alarms |

| Safety Controls |

| Starter |

| Turbocharger(s) |

| Valves and Valve Rotators |

| Vibration Isolators |

| Voltage |

| Water Pump |

| Water Separator |