System Function

Safety controls monitor key conditions like oil pressure, coolant temperature, overspeed, and abnormal electrical output. They are designed to alarm and shut down the generator before damage occurs. When safety controls have problems, they may trip when nothing is wrong or fail to trip during an actual fault which is the higher risk situation.

- Protective Monitoring: Sensors continuously measure critical parameters comparing actual values to safe operating limits triggering alarms when thresholds are exceeded.

- Automatic Shutdown: When sensor readings indicate dangerous conditions safety controls execute immediate engine shutdown preventing catastrophic damage to expensive components.

False trips reduce standby reliability while missed trips can allow overheating or damage to major components quickly. Problems often show up as intermittent alarms, unexplained shutdown logs, or unit that will not stay online under load.

Safety control testing video

Maintenance Schedule

How often should it be verified?

How often should sensors be replaced?

Safety controls are verified by checking sensors, wiring integrity, event history, and settings every quarter during PM1 inspections—not just cleared and reset. Annual testing during PM2 includes simulating fault conditions to verify proper shutdown response.

Environmental Considerations: Sensors in high vibration environments may experience accelerated wear or loosening of connections. Moisture intrusion into sensor connections creates false readings. Electromagnetic interference from nearby equipment affects sensor accuracy. Corrosion of sensor bodies or terminals in harsh environments causes drift or failure.

How you can tell it is acting up

- Nuisance Shutdowns: Generator shuts down without apparent cause or at operating conditions well within normal range.

- Safety Alarm History: Event log shows repeated safety warnings that clear before investigation revealing intermittent sensor or wiring problems.

- Generator Will Not Start: Safety controls prevent starting indicating fault condition that may not actually exist.

- Delayed Shutdown Response: Generator continues running with actual fault condition present indicating safety control failure.

- Sensor Reading Conflicts: Multiple sensors for same parameter show different values revealing sensor calibration or wiring problems.

Most asked question

“My generator keeps shutting down on safety alarms but readings look normal—what is wrong?”

Nuisance safety shutdowns typically indicate sensor or wiring problems not actual engine faults. Sensors can develop calibration drift reporting fault conditions when parameters are actually normal. Corroded connections create high resistance causing voltage drop that controller interprets as sensor fault. Damaged wiring or poor grounds create intermittent signals triggering shutdowns. Failed sensors may report mid-scale values appearing normal during static checks but failing under running conditions. We diagnose nuisance trips during PM1 by verifying sensor accuracy with calibrated test equipment, inspecting wiring for damage or corrosion, and reviewing detailed event logs showing exact fault sequence. Many nuisance trips are resolved by cleaning connections, replacing aged sensors, or correcting wiring issues rather than actual engine repairs. However never disable safety controls as they prevent catastrophic engine damage when real fault conditions occur.

Frequently Asked Questions

Can I bypass safety controls to keep generator running during outage?

Absolutely not. Safety controls prevent catastrophic engine damage. Bypassing controls to continue operation during fault conditions causes severe damage far exceeding cost of proper repair. Low oil pressure operation destroys bearings requiring complete engine rebuild. Operating with overheating causes head gasket failure and cylinder damage. Overspeed operation causes valve float and potential mechanical destruction. Safety shutdown during outage is far better outcome than destroyed engine requiring replacement. If safety controls trip, investigate and repair the actual problem rather than bypassing protection.

How are safety control setpoints determined?

Manufacturer establishes setpoints based on engine design and safe operating limits. Oil pressure setpoint set below minimum pressure required for bearing protection. Temperature setpoint set below level causing cylinder head or gasket damage. Overspeed setpoint set above normal governed speed but below mechanical damage threshold. Setpoints should never be adjusted without manufacturer approval. Increasing setpoints to prevent nuisance trips defeats protection allowing actual damage. Proper solution is fixing sensor or wiring problem causing false trips not adjusting setpoints.

What causes safety control sensor failures?

Age and thermal cycling degrade sensor accuracy over time. Vibration damages sensor internals or loosens connections. Contamination from oil or coolant affects sensor operation. Moisture intrusion corrodes internal electronics. Mechanical damage from impact or improper handling. Electrical surges from lightning or switching damage sensor circuits. Manufacturing defects cause premature failure. Most sensors have finite lifespan typically 5 to 10 years requiring replacement based on age and performance testing rather than waiting for failure.

Why test safety controls if they have never caused problems?

Safety controls must be verified functional before they are needed during actual fault conditions. Failed safety control discovered during testing can be repaired. Failed safety control discovered during actual overheat or low pressure event means catastrophic engine damage. Testing proves sensors read accurately, wiring is intact, and controller will execute proper shutdown sequence. Sensors can drift or fail without obvious symptoms during normal operation. Only testing under simulated fault conditions verifies protection remains effective. Cost of periodic testing trivial compared to engine replacement from undetected safety control failure.

Schedule Service

Generator Source services every make and model of commercial and industrial generators from 20kW to 4000kW. Our EGSA-certified technicians bring 50+ years of experience, and we are the largest reseller of new and used commercial generators in the country.

Call 877-866-6895 to speak with a specialist today!

Our Techs are EGSA Certified

Our certified EGSA technicians deliver exceptional, hands-on expertise that our customers rely on.

| Maintenance Item |

|---|

| ▼ 31 Point Inspection Items / PM1 |

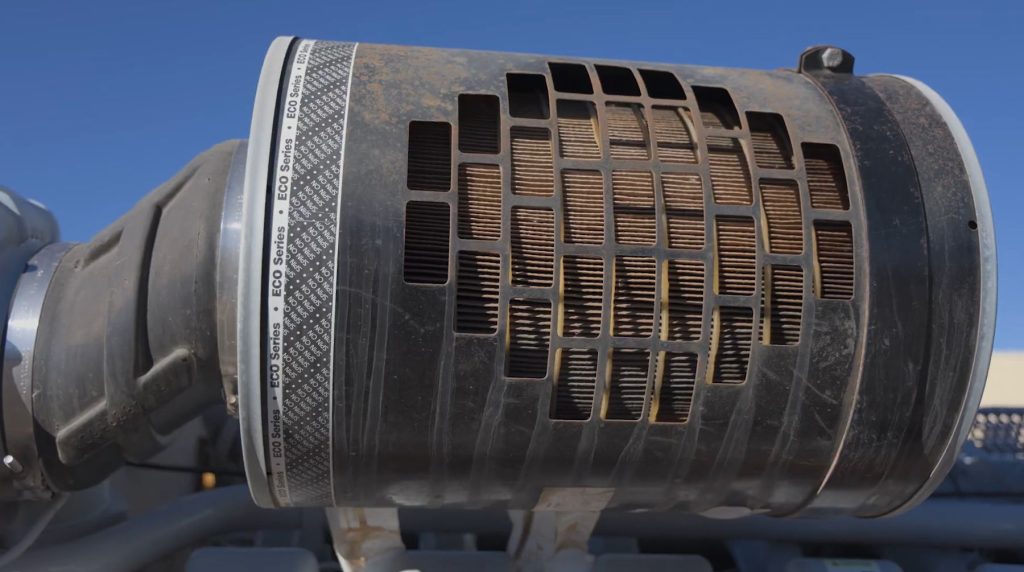

| Air Inlet System & Air Filter |

| Alternator |

| Barrel Insulation |

| Batteries |

| Battery Charger |

| Bearing(s) |

| Belts, Hoses & Connections |

| Block Heater |

| Breaker(s) |

| Collect Oil & Coolant Samples |

| Coolant & Coolant Filter(s) |

| Crankcase Breather(s) |

| Exhaust Manifold |

| Fan and Fan Drive |

| Fuel Filters – Prim/Sec |

| Fuel Lines & Connections |

| Fuel Tank & Rack |

| Gauges |

| Governor and controls |

| Jacket Water Heater |

| Oil & Oil Filter(s) |

| Radiator |

| Remote Annunciators/Alarms |

| Safety Controls |

| Starter |

| Turbocharger(s) |

| Valves and Valve Rotators |

| Vibration Isolators |

| Voltage |

| Water Pump |

| Water Separator |