System Function

The starter uses battery power to rotate the engine fast enough for compression and combustion to begin. Good starter performance depends on proper engagement, adequate cranking speed, and secure clean connections. When a starter begins to fail, cranking speed slows, engagement becomes inconsistent, or the starter may not turn.

- High Torque Cranking: The starter motor must produce sufficient torque to overcome engine compression and friction turning the engine fast enough typically 150 to 200 RPM for combustion to begin.

- Bendix Drive Engagement: Engagement mechanism must reliably mesh starter pinion with engine flywheel during cranking then disengage when engine starts preventing starter damage from overspeeding.

Electrical issues like voltage drop at cables or worn contacts can feel like mechanical failure and cause no start events. You may hear clicking or grinding that gets worse in cold weather.

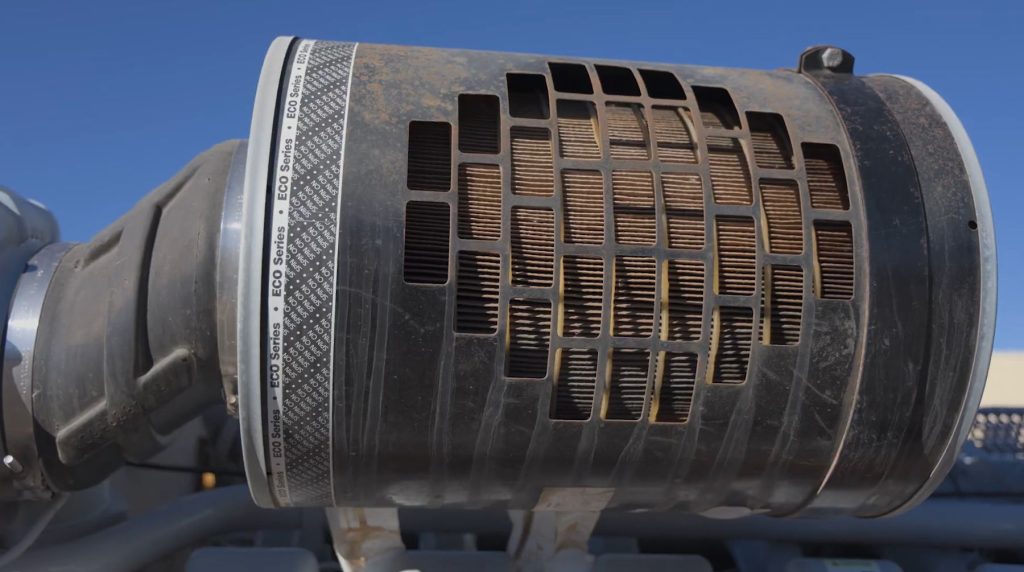

Starter maintenance video

Maintenance Schedule

How often should it be tested?

How often should it be replaced?

Starters are evaluated for current draw, connection condition and engagement quality every quarter during PM1 inspections—not just whether the engine eventually fires. Starters typically replaced every 3 to 5 years or based on cranking performance testing.

Environmental Considerations: Starters in cold climates work harder cranking cold thick oil requiring higher current draw. Humid coastal environments cause corrosion of terminals and internal components. Starters exposed to excessive heat from nearby exhaust components experience accelerated wear. Generators with frequent start cycles wear starters faster than standby-only operation.

How you can tell it is acting up

- Slow Cranking Speed: Engine turns over sluggishly taking longer than normal to reach starting RPM indicating starter weakness or electrical problems.

- Clicking Sound Without Cranking: Repeated clicking from solenoid without starter engagement revealing voltage drop or mechanical binding.

- Grinding Noise During Start: Harsh grinding sound indicating bendix drive not fully engaging with flywheel teeth.

- Intermittent Starting: Starter works normally sometimes but fails other times suggesting worn solenoid contacts or brushes.

- Starter Remains Engaged After Start: Grinding or whining continues after engine starts revealing bendix drive not disengaging properly.

Most asked question

“My starter eventually cranks the engine after several attempts—does it need replacement?”

Yes. Intermittent starter operation indicates imminent failure. Worn solenoid contacts create high resistance requiring multiple attempts to achieve good connection. Worn brushes reduce current flow slowing cranking speed. Weak permanent magnets from overheating reduce starting torque. Binding from contamination or worn bearings creates inconsistent engagement. Intermittent operation today typically becomes complete failure within weeks or months. During power outage when you need reliable starting, a marginal starter may completely fail leaving your facility without backup power. We test starters during PM1 measuring actual current draw and cranking RPM. Starters showing degraded performance should be replaced proactively rather than waiting for emergency failure. Cost of scheduled starter replacement is far less than emergency service call plus facility downtime from failed start during actual outage.

Frequently Asked Questions

How long do starters typically last?

Starter lifespan varies dramatically by duty cycle and operating conditions. Standby generators with monthly testing may get 10 to 15 years from starter. Generators with frequent starts or cold weather operation may require starter replacement in 3 to 5 years. Starter rated for limited number of starts typically 5000 to 10000 cycles. Measure starter performance not just age. Current draw testing and cranking speed measurement during PM1 reveals degradation before failure. Replace starter when testing shows performance decline regardless of age or hours.

What causes premature starter failure?

Extended cranking attempts overheat starter motor damaging windings and permanent magnets. Operating starter continuously for more than 30 seconds causes dangerous overheating. Inadequate battery capacity forces starter to work harder causing accelerated wear. Vibration from loose mounting or worn engine mounts damages starter internals. Moisture and corrosion degrade brushes and commutator. Oil contamination from leaking rear main seal damages bearings. Cold starting with thick oil creates excessive mechanical load. Most starter damage is preventable through proper maintenance and operating procedures.

Can starters be rebuilt or must they be replaced?

Many starters can be rebuilt replacing brushes, solenoid contacts, bearings and sometimes armature. Quality rebuild costs 50 to 70 percent of new starter price. However rebuilt starters may have reduced lifespan if housing or field coils are worn. Availability of rebuild kits varies by starter model. For critical standby generators, new starter provides better reliability and typically includes warranty. Rebuilt starters acceptable for backup but new starter recommended for primary emergency power. Labor cost for installation same whether rebuilding or replacing making new starter better value for reliability.

Why are proper cable connections critical for starter operation?

Voltage drop at cable connections dramatically reduces current available to starter. One volt drop at connection can reduce starting torque by 25 percent. Corroded terminals create high resistance that generates heat potentially melting connections. Loose cables vibrate causing intermittent contact. Undersized cables cannot carry required current causing voltage drop and overheating. All starter circuit connections should be clean, tight and properly crimped. During PM1 we clean connections and measure voltage drop during cranking. Proper connections ensure full battery power reaches starter for reliable starting under all conditions.

Schedule Service

Generator Source services every make and model of commercial and industrial generators from 20kW to 4000kW. Our EGSA-certified technicians bring 50+ years of experience, and we are the largest reseller of new and used commercial generators in the country.

Call 877-866-6895 to speak with a specialist today!

Our Techs are EGSA Certified

Our certified EGSA technicians deliver exceptional, hands-on expertise that our customers rely on.

| Maintenance Item |

|---|

| ▼ 31 Point Inspection Items / PM1 |

| Air Inlet System & Air Filter |

| Alternator |

| Barrel Insulation |

| Batteries |

| Battery Charger |

| Bearing(s) |

| Belts, Hoses & Connections |

| Block Heater |

| Breaker(s) |

| Collect Oil & Coolant Samples |

| Coolant & Coolant Filter(s) |

| Crankcase Breather(s) |

| Exhaust Manifold |

| Fan and Fan Drive |

| Fuel Filters – Prim/Sec |

| Fuel Lines & Connections |

| Fuel Tank & Rack |

| Gauges |

| Governor and controls |

| Jacket Water Heater |

| Oil & Oil Filter(s) |

| Radiator |

| Remote Annunciators/Alarms |

| Safety Controls |

| Starter |

| Turbocharger(s) |

| Valves and Valve Rotators |

| Vibration Isolators |

| Voltage |

| Water Pump |

| Water Separator |