System Function

Vibration isolators support the generator set and help prevent vibration from transferring into the skid, pad and connected piping and wiring. When they are the right height and stiffness they keep the unit stable and reduce fatigue stress on mounts and attachments. As isolators age they can sag, crack or break which makes a generator set unlevel.

- Vibration Damping: Isolators absorb engine vibration preventing transmission to building structure that would cause noise amplification and structural fatigue in mounting surfaces.

- Load Support: Isolators must support generator weight while maintaining proper height and stiffness balance allowing controlled movement without excessive deflection or instability.

That extra movement loosens hardware and puts stress on exhaust flex sections, coolant lines, fuel lines and conduits which can lead to leaks and connection failures. You may hear rattling or feel harsh vibration at certain RPM.

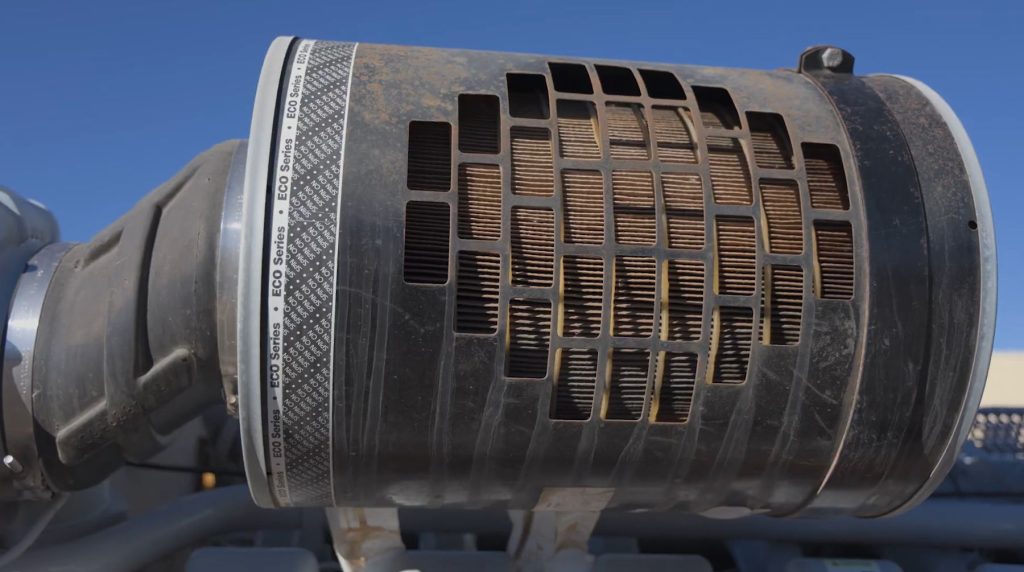

Vibration isolator inspection video

Maintenance Schedule

How often should it be inspected?

How often should it be replaced?

Isolators are checked for sag, cracking, mounting hardware condition and vibration levels every quarter during PM1 inspections—not just whether the generator looks level. Isolators typically replaced every 5 to 10 years based on condition or when vibration problems develop.

Environmental Considerations: Isolators exposed to oil or fuel contamination deteriorate rapidly as petroleum products attack rubber compounds. UV exposure on outdoor installations accelerates rubber aging and cracking. Extreme temperature cycling causes hardening and loss of damping properties. Isolators in high vibration environments from unbalanced generators experience accelerated wear.

How you can tell it is acting up

- Generator Unlevel: Visible sag or height difference between isolators indicating compression set or failure of isolator material.

- Cracks in Isolator Material: Visible splits or tears in rubber or elastomer material revealing age deterioration or overload damage.

- Excessive Vibration: Increased vibration felt throughout generator or building structure suggesting isolator hardening or failure.

- Loose Mounting Hardware: Bolts or nuts working loose from excessive movement indicating inadequate vibration isolation.

- Leaks at Connections: Fuel, coolant or exhaust leaks at flex connections caused by stress from excessive generator movement.

Most asked question

“My generator looks level—do the isolators really need inspection?”

Yes. Visual levelness does not confirm isolator condition. Isolators can appear acceptable while having lost damping properties from hardening or internal damage. Rubber compounds deteriorate over time losing elasticity even without visible cracking. Hardened isolators transmit more vibration to building structure causing noise problems and structural fatigue. Compressed isolators from overload or age may still support weight while providing inadequate vibration isolation. We inspect isolators during PM1 measuring actual height comparing to specifications and checking for cracks or deterioration. Vibration analysis reveals isolator effectiveness independently of visual appearance. Failed isolators create stress on connected piping potentially causing fuel, coolant or exhaust leaks. Isolator replacement is inexpensive preventive maintenance compared to repairing stress-related leaks or structural damage from excessive vibration transmission.

Frequently Asked Questions

How long do vibration isolators last?

Isolator lifespan varies by type and operating conditions. Spring isolators can last 20 plus years with minimal maintenance. Rubber or elastomer isolators typically last 5 to 10 years before hardening or cracking reduces effectiveness. Isolators exposed to oil, fuel or UV deteriorate much faster. Isolators supporting unbalanced generators wear faster from excessive vibration. Temperature extremes accelerate aging. Replace isolators based on condition inspection not just age as environmental factors dramatically affect service life.

What causes isolators to fail prematurely?

Oil or fuel contamination attacks rubber compounds causing swelling and deterioration. Overloading from undersized isolators or added equipment weight compresses isolators beyond design limits. UV exposure breaks down rubber molecular structure. Ozone from electrical equipment accelerates rubber aging. Extreme temperatures cause hardening or softening beyond design range. Unbalanced generators create excessive vibration accelerating wear. Poor installation with misaligned mounting surfaces creates stress concentrations. Most premature failures are preventable through proper selection installation and contamination prevention.

Can I replace individual isolators or must all be replaced together?

Replace complete set of isolators together. Isolators compress and harden at different rates based on load distribution. Mixing new and old isolators creates uneven support making generator unlevel and creating stress on frame. New isolators are stiffer than aged isolators disrupting vibration isolation characteristics. Cost of isolators is small compared to labor for installation making complete set replacement more economical than returning later to replace remaining isolators. Always replace full set maintaining uniform support and vibration isolation.

Why are properly sized isolators important?

Isolators must match generator weight and operating speed for effective vibration isolation. Undersized isolators compress excessively providing inadequate vibration isolation and causing generator to sit too low. Oversized isolators remain too stiff providing little damping. Natural frequency of isolator-generator system must be below operating frequency for effective isolation. Improper sizing can create resonance amplifying vibration instead of reducing it. Generator manufacturers specify correct isolator types and quantities. Always use isolators meeting specifications for weight capacity stiffness and application.

Schedule Service

Generator Source services every make and model of commercial and industrial generators from 20kW to 4000kW. Our EGSA-certified technicians bring 50+ years of experience, and we are the largest reseller of new and used commercial generators in the country.

Call 877-866-6895 to speak with a specialist today!

Our Techs are EGSA Certified

Our certified EGSA technicians deliver exceptional, hands-on expertise that our customers rely on.

| Maintenance Item |

|---|

| ▼ 31 Point Inspection Items / PM1 |

| Air Inlet System & Air Filter |

| Alternator |

| Barrel Insulation |

| Batteries |

| Battery Charger |

| Bearing(s) |

| Belts, Hoses & Connections |

| Block Heater |

| Breaker(s) |

| Collect Oil & Coolant Samples |

| Coolant & Coolant Filter(s) |

| Crankcase Breather(s) |

| Exhaust Manifold |

| Fan and Fan Drive |

| Fuel Filters – Prim/Sec |

| Fuel Lines & Connections |

| Fuel Tank & Rack |

| Gauges |

| Governor and controls |

| Jacket Water Heater |

| Oil & Oil Filter(s) |

| Radiator |

| Remote Annunciators/Alarms |

| Safety Controls |

| Starter |

| Turbocharger(s) |

| Valves and Valve Rotators |

| Vibration Isolators |

| Voltage |

| Water Pump |

| Water Separator |