System Function

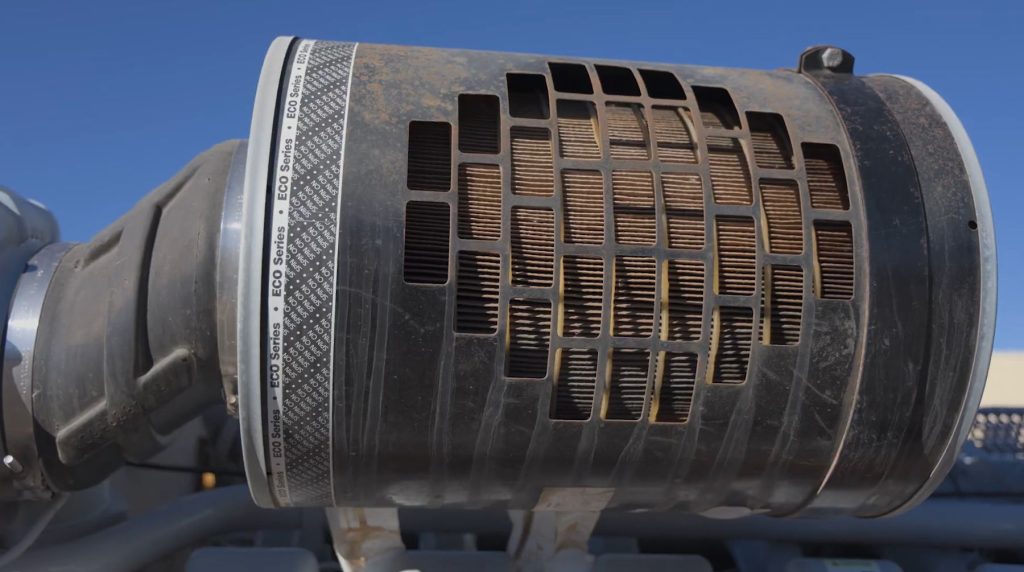

The air intake assembly is a two-part critical system acting as the respiratory tract for your generator.

- The Air Inlet System: This includes the piping, hoses, clamps, rain caps, and housing that route outside air to the turbocharger. Its job is to maintain a sealed, airtight path to prevent “dusting” (unfiltered air entering the engine).

- The Air Filter: Sitting inside the housing, the filter media captures abrasive particulates (silica, dirt, carbon) and environmental contamination before they reach the combustion chamber.

Clean, unrestricted airflow is non-negotiable. A sealed system and a clean filter ensure Volumetric Efficiency—guaranteeing the engine gets the large, steady oxygen volume required for complete combustion, preventing wet stacking and turbocharger failure.

Air inlet system and air filter maintenance video

Maintenance Schedule

How often it should be inspected?

How often it should the air filters be replaced?

Standard protocol is to replace air filters every 12 months. However, we utilize a “Condition-Based” approach for extreme environments—checking for restrictions, leaks, contamination, and overall condition, not just replacing based on hours. In dusty regions like Texas or the Southwest, filters may reach maximum differential pressure in less than 12 months. In humid Coastal Zones, moisture can swell the paper media, necessitating earlier replacement to prevent airflow starvation.

The System (Infrastructure): When Needed – The inlet piping, rubber elbows, and hump hoses are not replaced on a calendar schedule. They are replaced based on physical degradation. During our PM1, if we detect rubber hardening, stress cracks, or rusted housing, we recommend immediate repair to maintain system vacuum integrity.

How you can tell it is acting up

- High Differential Pressure: The “Pop-up” restriction indicator on the housing trips to red.

- Filter Collapse: In severe cases, a completely clogged filter can collapse inward, creating a bypass condition that allows debris into the engine.

- Black Exhaust Smoke: Starved of air, the engine runs “rich” (too much fuel), creating unburned soot.

- Sluggish Load Acceptance: The generator struggles or stalls when the automatic transfer switch (ATS) applies the building load.

- Rough Running or Shutdown: Severe restriction can cause unstable RPMs or complete shutdown under load.

- Turbocharger Surging: Audible “woofing” or uneven RPMs as the turbo struggles to pull air.

- Visible Contamination: Fine dirt coating the inside of the intake piping (a sign of a system leak bypassing the filter).

Most asked question

“Can I just clean the air filter with compressed air instead of replacing it?”

No. We strongly advise against this. Blowing compressed air through an industrial filter often creates microscopic tears in the paper media. These invisible holes allow abrasive silica to pass directly into the engine cylinders, acting like sandpaper on your piston rings. It is cheaper to replace the filter than to rebuild the engine.

Frequently Asked Questions

How often should a generator air inlet system and air filter be inspected?

Generator Source recommends inspecting the air inlet system and filter quarterly as part of a PM1 inspection. In dusty, industrial, or high-use environments, airflow restrictions can develop quickly, making routine inspections critical to protecting engine health and maintaining reliable power.

What are the early warning signs of an air inlet or air filter issue?

Beyond visible smoke, the most reliable early warning is the Air Restriction Indicator. If this gauge moves into the red zone, the filter is creating excessive drag on the turbocharger. Left unaddressed, this causes high exhaust gas temperatures (EGTs) and accelerated valve wear.

What happens if airflow issues are ignored?

If a filter collapses or a hose cracks, the engine will ingest debris. This causes “dusting,” which scuffs cylinder liners and destroys compression. If the filter simply clogs, the engine will suffocate, leading to wet stacking, power loss, and potential shutdown under load.

Should air inlet or air filter issues be handled by a professional technician?

Yes. A professional does more than swap a filter; we verify the integrity of the entire induction system. A simple loose clamp downstream of the filter can destroy a $50,000 engine. Generator Source’s EGSA-certified technicians ensure the system is sealed from the rain cap down to the turbo inlet.

Service Request

Still have questions?

Generator Source specializes in low-hour, used, new, and surplus generator sets. We have a wide variety of generator sizes and models to fit any project. We are not a broker, we own what we sell.

Call us today (877-866-6895) or click Contact Us to be connected with one of our experienced sales reps.

We have 350+ generators in stock and ready to ship!