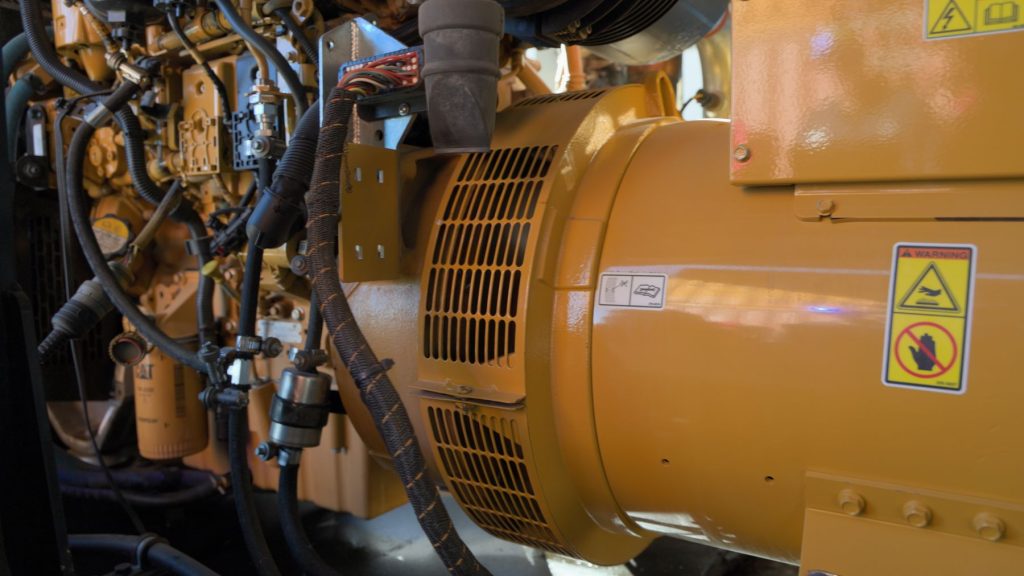

System Function

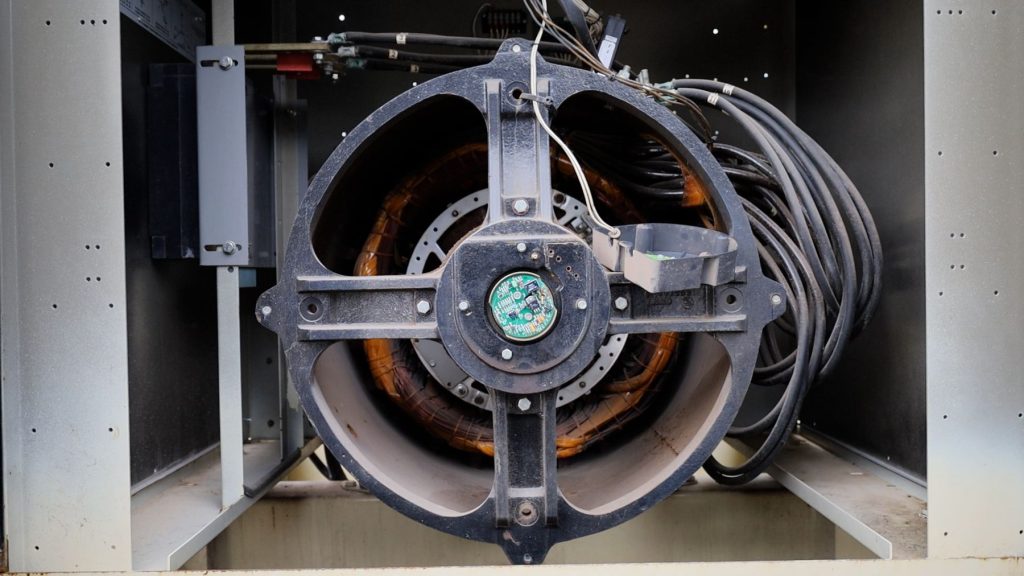

The alternator’s barrel insulation protects the stator windings inside the alternator housing. Its job is to keep electrical current properly isolated from the frame while handling heat, vibration and humidity over time. Insulation health is a big part of alternator reliability, because the alternator’s ability to carry the load depends on that insulation staying clean and intact.

- The Varnish Coating: A protective layer that seals copper windings against moisture contamination and prevents winding-to-winding shorts.

- The Structural Insulation: Physical barriers between windings and the frame that prevent electrical leakage to ground even under extreme heat and vibration.

When barrel insulation is compromised, you can get leakage to ground or winding-to-winding shorts that may show up as unstable or low voltage, nuisance trips, unusual heating or a burnt varnish smell.

Barrel insulation inspection video

Maintenance Schedule

How often should it be inspected?

We look for contamination and damage inside the alternator and verify insulation condition with proper testing every quarter during PM1 inspections—not just whether the unit is making voltage. Insulation testing with a megohmmeter reveals deterioration before catastrophic failure occurs.

Environmental Considerations: In humid coastal environments, moisture accelerates varnish breakdown and creates conductive paths to ground. Dusty industrial settings allow contamination buildup that creates tracking paths across insulation surfaces. Both conditions dramatically shorten insulation life.

How you can tell it is acting up

- Unstable Voltage Output: Voltage fluctuates under steady load as insulation deterioration creates intermittent leakage paths.

- Ground Fault Alarms: Controller detects current leaking to frame through compromised insulation.

- Burnt Varnish Smell: Distinctive acrid odor from overheating insulation as electrical resistance increases.

- Reduced Load Capacity: Generator cannot carry rated load due to increased internal resistance from insulation breakdown.

- Excessive Alternator Heat: Abnormally hot alternator housing indicating internal electrical losses from poor insulation.

Most asked question

“Can insulation be repaired, or does the whole alternator need replacement?”

It depends on the extent of damage. Minor surface contamination can sometimes be cleaned during alternator maintenance. However, once the varnish coating breaks down or winding-to-winding insulation degrades, the alternator requires professional rebuild or replacement. There is no field repair for compromised barrel insulation—attempting to “clean it up” only delays inevitable catastrophic failure and risks damaging the entire generator during an outage.

Frequently Asked Questions

How is barrel insulation tested

We use a megohmmeter insulation resistance tester to measure resistance between windings and ground. The test applies high voltage typically 500 to 1000V and measures leakage current. Readings below manufacturer specifications indicate insulation deterioration. Temperature and humidity affect readings so we test under controlled conditions and track trends over time rather than relying on single measurements.

What causes insulation to fail

Heat moisture and contamination are the primary enemies. Continuous overloading creates excess heat that degrades varnish. Humidity penetrates through failed space heaters creating conductive paths. Dust and oil contamination form tracking paths across insulation surfaces. Vibration from loose mounting or bearing wear can also crack insulation mechanically. Most failures result from a combination of these factors rather than a single cause.

Can I continue running with degraded insulation

No. Compromised insulation degrades exponentially not gradually. A generator showing early insulation problems today will likely experience complete failure within weeks or months not years. Continuing to run risks catastrophic alternator failure during a critical outage potential fire hazard from internal arcing and possible damage to connected equipment from voltage instability. When insulation tests fail immediate action is required.

How long should barrel insulation last

In properly maintained generators operating in controlled environments alternator insulation can last 20 plus years. However harsh conditions dramatically reduce this lifespan. Coastal humidity dusty industrial environments frequent overloading or failed space heaters can accelerate insulation degradation. This is why regular insulation testing during PM1 inspections is critical it catches deterioration before catastrophic failure occurs.

Service Request

Still have questions?

Generator Source specializes in low-hour, used, new, and surplus generator sets. We have a wide variety of generator sizes and models to fit any project. We are not a broker, we own what we sell.

Call us today (877-866-6895) or click Contact Us to be connected with one of our experienced sales reps.

We have 350+ generators in stock and ready to ship!