System Function

The block heater is designed to keep the engine warm while the generator is offline. The block heater warms critical engine components directly maintaining proper engine temperatures so oil flows correctly and the engine can reach starting speed quickly.

- Direct Component Warming: Block heater applies heat directly to engine block warming cylinder walls bearings and other critical components reducing thermal shock during cold starts.

- Oil Viscosity Management: Maintaining engine warmth keeps oil at proper viscosity allowing immediate lubrication during startup protecting internal components from friction damage during initial rotation.

When block heaters fail the engine starts cold. Cold starts increase internal friction slowing cranking speed delaying oil circulation and placing additional load on starter and batteries. Repeated cold starts accelerate wear and shorten engine life.

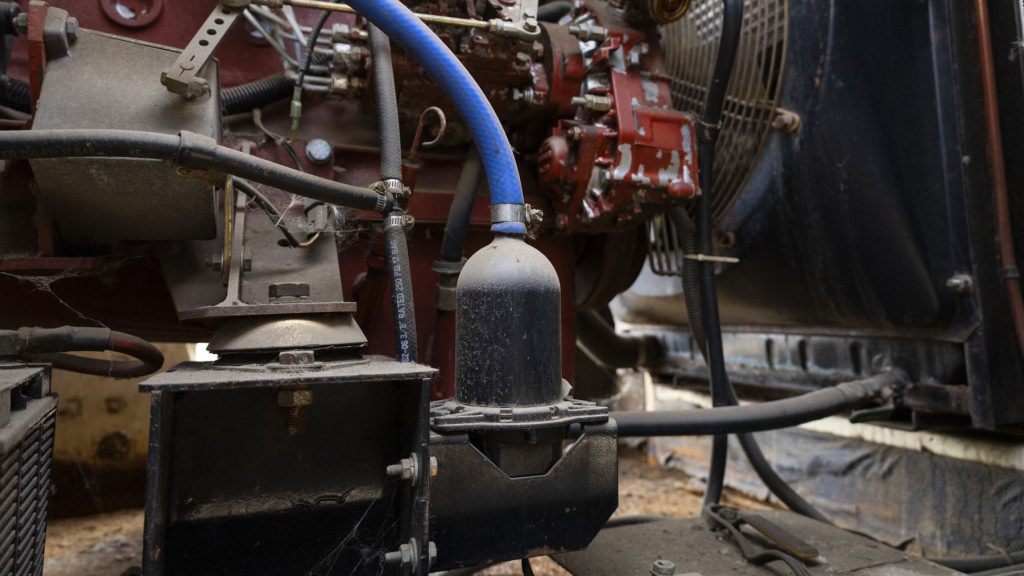

Block heater maintenance video

Maintenance Schedule

How often should it be tested?

Block heaters are checked for electrical draw proper operation and actual temperature increase every quarter during PM1 inspections—not just whether the engine eventually starts.

Environmental Considerations: Block heaters in cold climates experience higher duty cycles requiring more frequent inspection. Generators in outdoor installations face moisture intrusion affecting electrical connections. Facilities with unreliable utility power may have intermittent heater operation. High ambient temperatures in warm climates may mask heater failures until cold weather arrives.

How you can tell it is acting up

- Cold Engine Block: Engine block cold to touch despite heater being powered indicating heater element failure or loss of electrical connection.

- Extended Cranking Time: Engine requires prolonged cranking before starting suggesting cold thick oil from inadequate block warming.

- No Electrical Draw: Ammeter shows no current flow to heater circuit revealing open element or wiring problem.

- Slow Cranking Speed: Starter labors during cold weather start indicating increased friction from cold engine components.

- White Smoke on Start: Excessive white smoke during cold start revealing poor combustion from cold engine temperatures.

Most asked question

“My generator starts fine in cold weather—does the block heater really matter?”

Yes. Engine eventually starting does not mean block heater is working properly or that cold starts are not causing damage. Cold starts place enormous stress on internal engine components. Thick cold oil does not flow quickly to bearings and cylinder walls during initial rotation. Metal components contract in cold temperatures creating larger clearances. These factors combine to create metal-on-metal contact during critical first seconds of operation. Cumulative damage from repeated cold starts reduces engine life by thousands of hours. Block heaters maintain proper engine temperature ensuring oil flows immediately and components remain at normal operating clearances.

Frequently Asked Questions

How does cold weather affect engine starting?

Cold temperatures dramatically increase oil viscosity making oil thick and slow-moving. This increased resistance makes engine harder to rotate requiring more power from starter and batteries. Cold metal components have larger clearances allowing oil film to escape reducing lubrication during initial rotation. Diesel fuel thickens in cold weather affecting injection spray patterns. Battery capacity drops significantly in freezing temperatures reducing available cranking power. These factors combine making cold starts extremely demanding on all starting components. Block heaters maintain engine warmth eliminating these cold start problems.

What temperature should block heater maintain?

Block heaters typically maintain engine temperature between 90F and 120F depending on heater wattage and ambient conditions. This temperature range keeps oil fluid enough for immediate circulation while preventing thermal stress from excessive heating. Temperature should be verified during service using infrared thermometer on engine block not just checking for warm surfaces. Insufficient warming indicates heater element degradation or electrical supply problems. Excessive temperature suggests thermostat failure or incorrect heater sizing.

How much power does block heater consume?

Block heaters typically consume between 500 and 1500 watts depending on engine size and heater design. Continuous operation costs are minimal compared to engine protection provided. Some installations use timers activating heaters only during coldest periods reducing power consumption. However generators requiring immediate emergency response should have heaters running continuously maintaining constant readiness. Power consumption should be verified during PM1 using amp meter confirming heater element is drawing proper current. Higher or lower current indicates element problems requiring investigation.

Can block heaters cause engine damage?

Properly sized and functioning block heaters cannot damage engines. However excessive heating from failed thermostats or oversized heaters can cause problems. Overheating can boil coolant in immediate vicinity of heater creating localized hot spots. This can damage gaskets or warp components. Most quality block heaters include thermostatic control preventing overheating. Regular inspection during PM1 verifies proper operation and temperature control. Benefits of proper block heating far outweigh minimal risks from correctly installed maintained heaters.

Service Request

Still have questions?

Generator Source specializes in low-hour, used, new, and surplus generator sets. We have a wide variety of generator sizes and models to fit any project. We are not a broker, we own what we sell.

Call us today (877-866-6895) or click Contact Us to be connected with one of our experienced sales reps.

We have 350+ generators in stock and ready to ship!