System Function

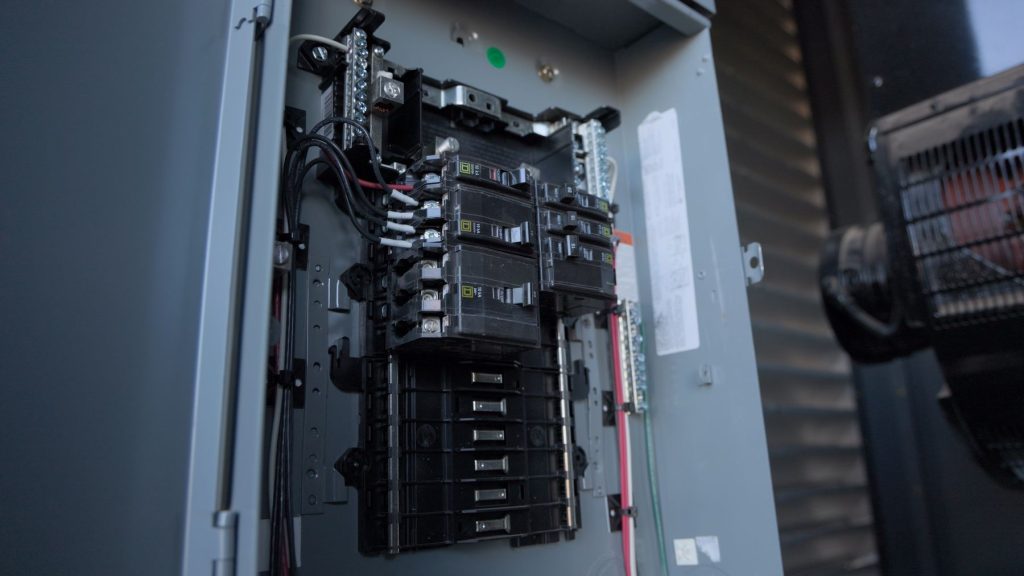

The generator breaker controls power leaving the generator and provides protection against overloads and faults. It must close smoothly, hold under load, and trip correctly when a protective condition occurs. When breaker problems develop, the generator may run but power does not reach the load or the breaker trips unexpectedly.

- Power Control: The breaker makes and breaks electrical connection between generator and load, handling high current during normal operation and fault conditions without welding contacts or failing to open.

- Overcurrent Protection: Trip mechanisms detect overload and short circuit conditions, disconnecting the generator before damage occurs to windings or connected equipment.

Heat damage, weak mechanisms and loose terminations can cause nuisance trips or poor contact which creates additional resistance. In some cases, the system appears normal until a real load event exposes the problem.

Breaker inspection and testing video

Maintenance Schedule

How often should it be inspected?

Breakers are inspected for mechanical action, heat signs, secure terminals, and proper operation under load every quarter during PM1 inspections—not just whether the handle is in the on position.

Environmental Considerations: Breakers in dusty environments accumulate contamination that interferes with contact surfaces and trip mechanisms. Humid environments cause oxidation of contacts increasing resistance. High ambient temperatures accelerate insulation breakdown.

How you can tell it is acting up

- Nuisance Tripping: Breaker trips without apparent overload or at loads well below rated capacity.

- Breaker Hot to Touch: Enclosure significantly warmer than surrounding components revealing high resistance connections.

- Burnt Smell Near Breaker: Acrid odor from overheated insulation indicating dangerous temperature rise.

- Difficulty Operating Handle: Handle requires excessive force suggesting binding in mechanism.

- Visible Arcing or Sparking: Flash or sparks during operation indicating poor contact surface.

Most asked question

“The breaker has not tripped—does that mean it is working properly?”

Not necessarily. Breakers can have serious problems while still remaining closed. Oxidized contacts create high resistance generating excessive heat even under normal load. Weak trip mechanisms may fail during actual fault conditions. We inspect breakers to detect hot spots, measure contact resistance, and verify mechanical operation. A breaker that appears fine while idle may fail catastrophically during load transfer when your facility needs it most.

Frequently Asked Questions

What causes breaker contacts to fail?

Arcing during operations erodes contact surfaces over time. Oxidation from humidity creates insulating film increasing resistance. Overheating from loose connections causes contact material to pit and deform. Poor contact pressure from worn springs prevents full surface engagement.

Can I use a standard circuit breaker instead of generator rated breaker?

No. Generator rated breakers are specifically designed for high inrush currents during load pickup ability to interrupt fault current at generator voltage and withstand reverse power conditions. Always use breakers meeting generator manufacturer specifications.

Why does my breaker trip when load is well below rating?

Nuisance tripping indicates breaker degradation. Trip mechanisms can weaken over time causing premature operation. Thermal memory from previous high loads makes breakers trip sensitive. Contact resistance from oxidation creates local heating that triggers thermal trips.

Service Request

Still have questions?

Generator Source specializes in low-hour, used, new, and surplus generator sets. We have a wide variety of generator sizes and models to fit any project. We are not a broker, we own what we sell.

Call us today (877-866-6895) or click Contact Us to be connected with one of our experienced sales reps.

We have 350+ generators in stock and ready to ship!