System Function

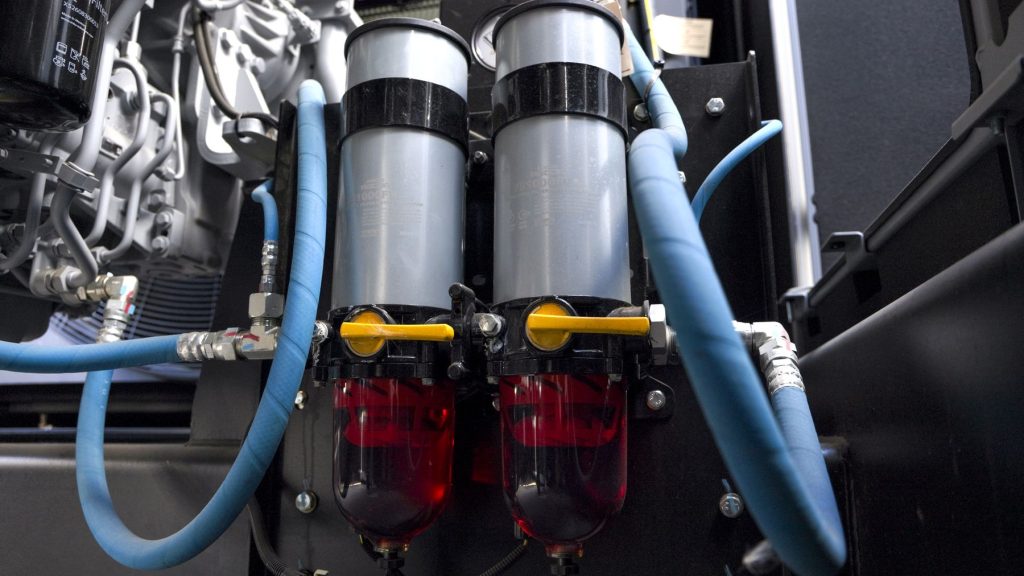

Fuel supply system stores fuel and delivers it to the engine cleanly and consistently. Whether diesel tank with supply and return lines, natural gas feed with regulators and piping, or hybrid system, the goal is the same. A sealed properly routed delivery path that maintains stable flow and pressure when the generator takes load.

- Leak-Free Delivery: All fuel connections must remain sealed under pressure and vibration preventing fuel loss, air intrusion, or vapor escape that compromises engine operation.

- Proper Routing: Fuel lines must be routed away from heat sources and sharp edges with adequate support preventing chafing, kinking or stress that causes leaks or restrictions.

When problems develop you may see wet fittings or fuel odor, or have small leaks, restrictions, or air intrusion that lead to hard starts, uneven running, surging or shutdowns under load.

Fuel line inspection video

Maintenance Schedule

How often should it be inspected?

Storage and piping are inspected for leaks and routing, contamination or restriction, and fuel supply stability under load every quarter during PM1 inspections—not just whether the unit starts. Fuel lines and connections are pressure tested periodically to detect leaks before they cause operational problems.

Environmental Considerations: Fuel systems in earthquake zones require flexible connections and seismic restraints. Outdoor fuel lines exposed to UV deteriorate faster requiring protective covers. Underground fuel lines may experience corrosion from soil conditions. Generators in cold climates may experience fuel gelling in lines requiring insulation or heating systems.

How you can tell it is acting up

- Fuel Odor Near Generator: Strong diesel or gas smell indicating leak in fuel supply or return lines.

- Wet Connections or Staining: Fuel residue visible on fittings or lines revealing active or previous leaks.

- Hard Starting After Sitting: Engine cranks extensively before starting suggesting air intrusion into fuel system overnight.

- Engine Surging During Operation: RPM fluctuation under steady load indicating inconsistent fuel delivery from restriction or air intrusion.

- Fuel Level Drops Without Running: Tank level decreases when generator is not operating revealing fuel leak in supply system.

Most asked question

“I smell diesel occasionally but do not see any leaks—should I be concerned?”

Absolutely. Fuel odor indicates vapor escape even if no visible liquid leak exists. Small weeping leaks at fittings allow fuel to evaporate before forming visible puddles especially in warm environments or with air movement. Fuel vapor is flammable creating fire hazard particularly in enclosed generator rooms. Vapor also indicates air intrusion point in supply system. Air entering fuel system during shutdown causes hard starting and may allow fuel to drain back to tank requiring extensive cranking. We pressure test fuel systems during PM1 to detect leaks too small for visual inspection. Any fuel odor requires immediate investigation and repair regardless of visible evidence.

Frequently Asked Questions

What causes air intrusion into fuel systems?

Loose fittings on suction side of fuel system allow air to enter when pump creates vacuum during cranking. Cracked or deteriorated fuel lines develop pinholes that admit air. O-rings and gaskets harden with age losing sealing capability. Fuel starvation from plugged filters creates high vacuum that draws air past normally sealed connections. Low fuel level in tank allows pump to draw air during vehicle motion or vibration. Any air in fuel system prevents starting or causes rough running requiring system bleeding.

Can I use automotive fuel line on my generator?

Not recommended. Generator fuel systems require specific hose types rated for diesel or natural gas service. Automotive fuel line may not resist diesel fuel causing swelling or deterioration. Fuel injection systems require hose rated for high pressure. Natural gas systems require hose compatible with gas and rated for gas pressure. Incorrect hose types deteriorate rapidly causing leaks or restrictions. Always use fuel line meeting generator manufacturer specifications for material type, pressure rating and temperature range.

Why must fuel lines be properly supported?

Unsupported fuel lines vibrate with engine operation causing fatigue failure at connections or creating chafing where lines contact other components. Vibration also loosens fittings allowing leaks or air intrusion. Proper support prevents stress concentration at fittings and maintains proper routing away from heat sources. Lines must have adequate flexibility to accommodate engine movement during operation without straining connections. Support spacing should follow manufacturer recommendations typically every 18 to 24 inches.

Service Request

Still have questions?

Generator Source specializes in low-hour, used, new, and surplus generator sets. We have a wide variety of generator sizes and models to fit any project. We are not a broker, we own what we sell.

Call us today (877-866-6895) or click Contact Us to be connected with one of our experienced sales reps.

We have 350+ generators in stock and ready to ship!