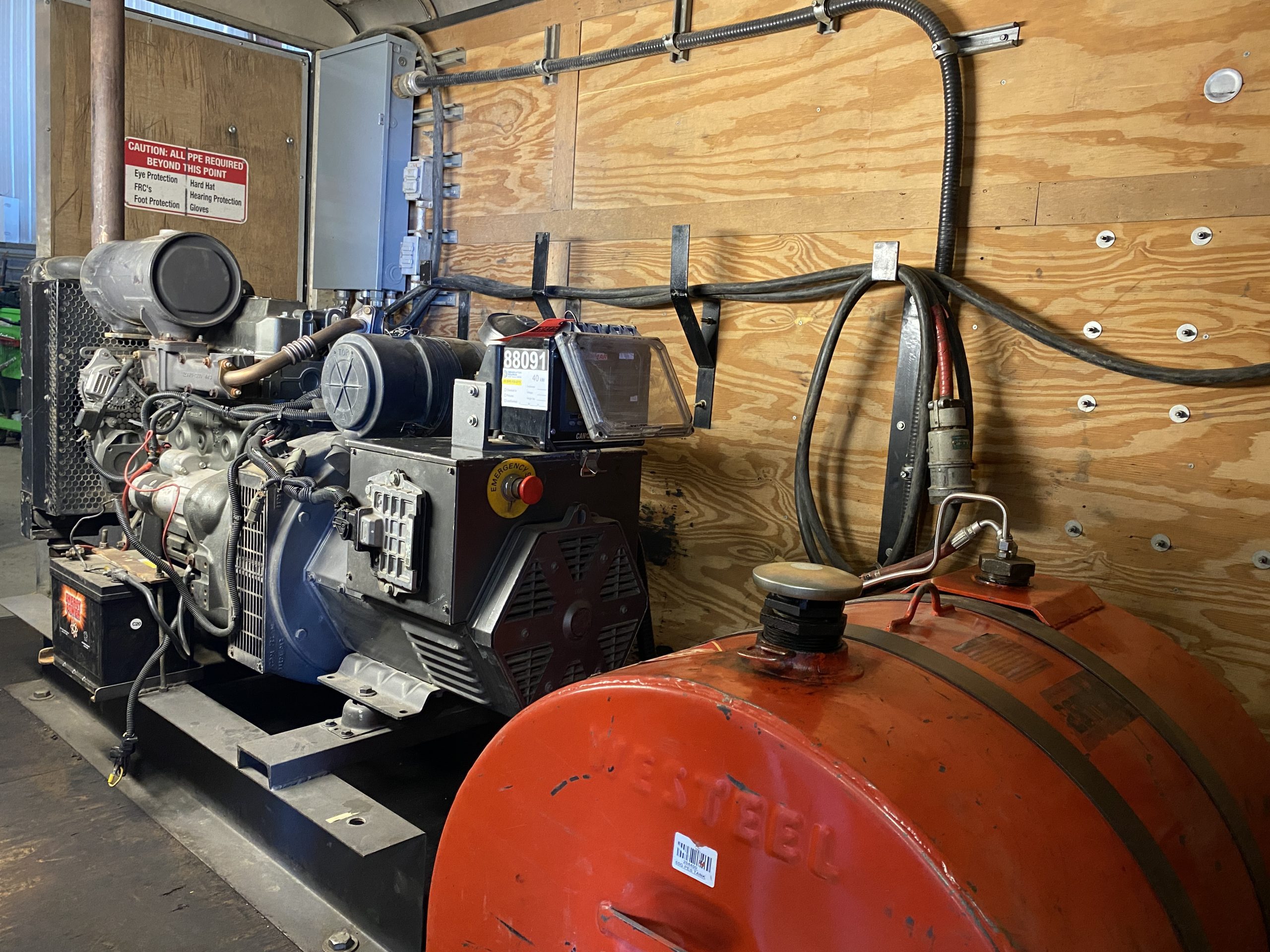

System Function

Fuel supply system stores fuel and delivers it to the engine cleanly and consistently. Whether diesel tank with supply and return lines, natural gas feed with regulators, or hybrid system, the goal is the same. A sealed properly routed delivery path that maintains stable flow and pressure when the generator takes load.

- Fuel Storage: Tank must store adequate fuel volume for required run time while preventing contamination from water, sediment, or microbial growth that degrades fuel quality.

- Contamination Prevention: Proper tank design with sealed fill caps, water drains, and ventilation prevents contamination while allowing thermal expansion without creating vacuum or pressure.

Contamination is a major factor including water or sediment in liquid fuel storage or debris in piping and regulators. When problems develop you may have restrictions or air intrusion that lead to hard starts or shutdowns under load.

Fuel tank maintenance video

Maintenance Schedule

How often should it be inspected?

How often should fuel be polished?

Fuel tanks are inspected for leaks, water accumulation, sediment buildup and proper ventilation every quarter during PM1 inspections. Annual fuel polishing during PM2 service removes accumulated water and contaminants maintaining fuel quality for reliable operation.

Environmental Considerations: Underground tanks in high water table areas experience more water intrusion requiring more frequent inspection. Tanks exposed to large temperature swings accumulate more condensation. Biodiesel fuel supports microbial growth requiring biocide treatment. Tanks near saltwater experience accelerated external corrosion of steel components.

How you can tell it is acting up

- Water in Fuel Samples: Free water visible in fuel or filter bowls indicating tank condensation or groundwater intrusion.

- Microbial Growth in Tank: Dark stringy material in fuel indicating biological contamination from bacteria or fungus growth.

- Sediment in Tank Bottom: Visible accumulation of rust, dirt or degraded fuel particles settling in tank.

- Fuel Smells Rancid: Off odor indicating degraded fuel from age or biological contamination.

- Tank Leaks or Corrosion: Visible fuel seepage, rust perforation, or structural deterioration of tank material.

Most asked question

“My fuel tank is only a few years old—does it really need inspection and maintenance?”

Absolutely. Fuel contamination happens in all tanks regardless of age. Daily temperature cycling causes moisture in tank air space to condense on cool tank walls dripping into fuel. Within months this creates sufficient water for microbial growth. Bacteria and fungus feed on diesel fuel creating dark slimy biomass that plugs filters and corrodes fuel system components from acidic byproducts. Rust particles from steel tanks accumulate even in new tanks. Sediment from fuel delivery settles in tank bottom. Without regular inspection and fuel polishing this contamination reaches your engine during emergency operation causing shutdown exactly when you need power most. Annual fuel polishing and tank cleaning are essential preventive maintenance.

Frequently Asked Questions

How often should fuel be polished?

Fuel should be polished annually during PM2 service for stored diesel fuel. More frequent polishing may be required for biodiesel blends or tanks with history of contamination. Polishing process circulates fuel through filtration removing water, sediment and microbial contamination. Fuel testing before and after polishing confirms contamination removal and fuel quality. Emergency polishing required if fuel samples show excessive water or biological growth. Never operate generator on heavily contaminated fuel as injection system damage will occur.

What is microbial growth in diesel fuel?

Bacteria and fungus that grow at water-fuel interface in tanks. Microbes feed on diesel creating dark slimy biomass commonly called diesel bug or algae though it is not algae. Microbial growth produces acidic byproducts that corrode tanks and fuel system components. Biomass plugs filters and creates starting problems. Growth accelerates in warm humid conditions and with biodiesel fuels. Biocide treatment kills existing growth but dead biomass must be removed through fuel polishing. Prevention requires keeping tanks full minimizing condensation and periodic biocide treatment.

Should I keep my diesel fuel tank full or empty when not in use?

Keep tank as full as possible when generator is on standby. Full tank minimizes air space reducing condensation formation. Condensation creates water contamination and microbial growth. Empty tanks accumulate more moisture and rust from exposed internal surfaces. However fuel should not be stored indefinitely. Diesel fuel degrades over 12 to 18 months forming varnish and sediment. Use fuel stabilizers for storage beyond 6 months. Rotate fuel through use and refilling to maintain fresh fuel supply.

How do I know if my underground fuel tank is leaking?

Unexplained fuel level drops indicate leakage. However small leaks may be masked by fuel deliveries. Tank monitoring systems provide continuous leak detection. Annual tank integrity testing using pressure decay or vacuum testing detects leaks before environmental contamination occurs. Vegetation stress or soil discoloration near tank suggests fuel leak. Groundwater sampling near tanks can detect contamination. Many jurisdictions require leak detection systems and periodic testing for underground storage tanks. Never ignore suspected leaks as environmental liability is severe.

Service Request

Still have questions?

Generator Source specializes in low-hour, used, new, and surplus generator sets. We have a wide variety of generator sizes and models to fit any project. We are not a broker, we own what we sell.

Call us today (877-866-6895) or click Contact Us to be connected with one of our experienced sales reps.

We have 350+ generators in stock and ready to ship!