System Function

Remote annunciation and alarms provide status and fault indication when the generator is monitored from another room or building. They rely on stable power, correct wiring, and proper communication settings to mirror what the controller reports in real time. When annunciators malfunction, alarms may not display, may show up late, or may report the wrong condition.

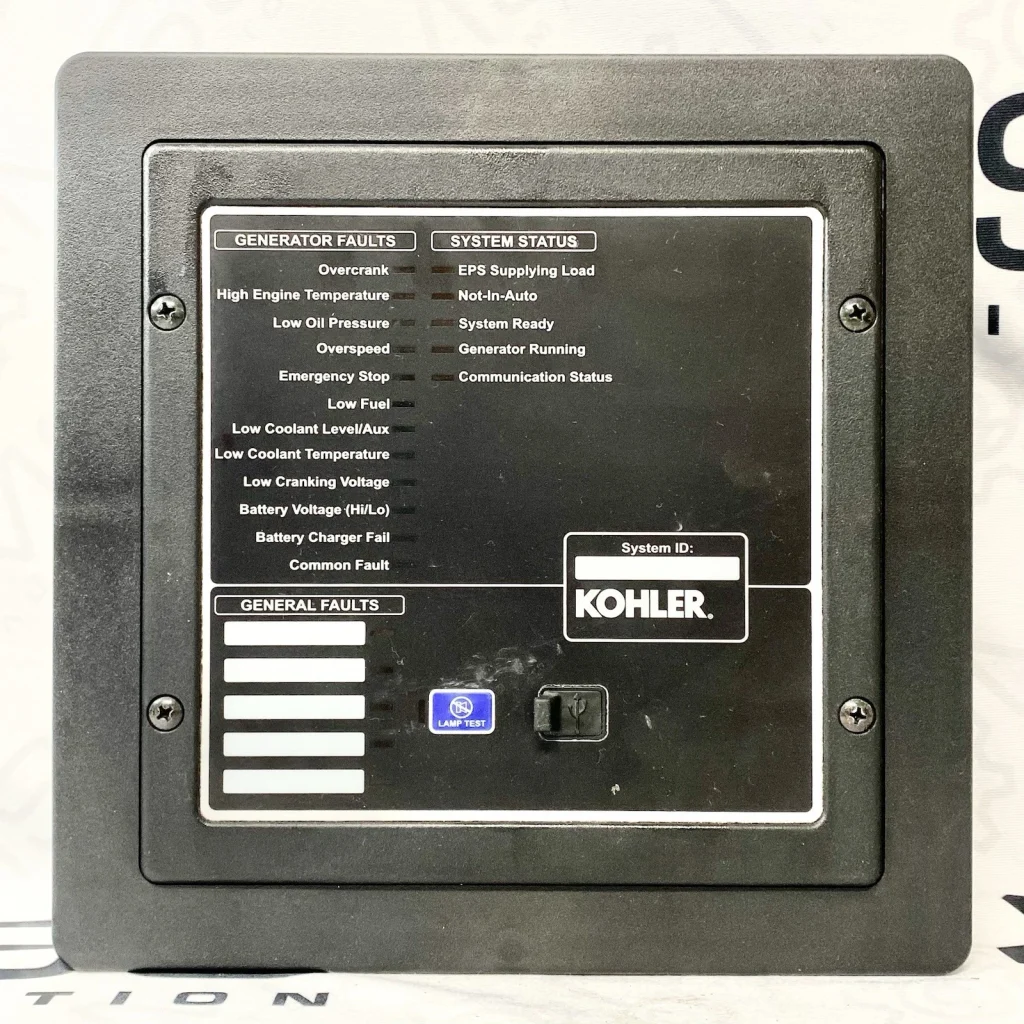

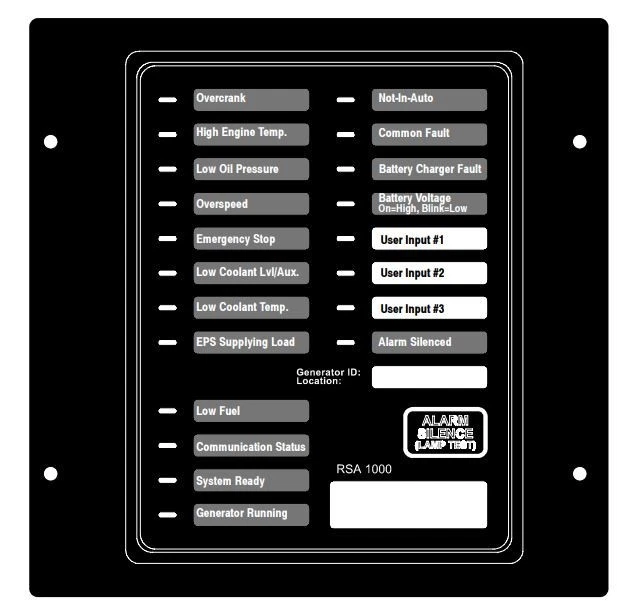

- Status Indication: Annunciator panels display generator operating status, fault conditions, and alarm states allowing remote monitoring without accessing generator room.

- Communication Interface: Digital communication protocols or hardwired relay contacts transfer status information from generator controller to remote displays ensuring immediate fault notification.

Common causes include communication loss, misconfigured connection points, weak power supplies, or damaged wiring. This results in lack of visibility into operation status of the generator.

Remote annunciator testing video

Maintenance Schedule

How often should it be tested?

Remote annunciators are inspected by confirming communications, triggering test alarms, and validating each point every quarter during PM1 inspections—not just checking the screen powers on. Communication wiring and power supplies verified for proper operation.

Environmental Considerations: Annunciator panels in unconditioned spaces experience temperature and humidity extremes affecting electronics reliability. Long wiring runs in electrically noisy environments may experience signal interference. Corrosion of connection terminals in coastal environments creates intermittent communication failures. Lightning strikes can damage communication circuits requiring surge protection.

How you can tell it is acting up

- Annunciator Not Updating: Remote panel shows stale information not reflecting current generator status indicating communication failure.

- Intermittent Alarms: Remote panel displays alarms that clear without cause or show conflicting status suggesting wiring or connection problems.

- Panel Shows All Lights: Multiple simultaneous alarm indications suggesting panel power or ground fault rather than actual generator faults.

- Delayed Alarm Response: Remote panel alarms lag behind actual generator status by seconds or minutes revealing communication slowness.

- No Power to Panel: Annunciator dark or shows error codes indicating power supply failure or wiring damage.

Most asked question

“My remote annunciator panel lights up—does that mean it is working correctly?”

Not necessarily. Panel with power does not confirm accurate status indication or alarm communication. Annunciators can show normal status while communication link to generator controller has failed preventing alarm transmission. Wiring faults may allow some status points to work while others fail. Incorrect alarm mapping causes annunciator to display wrong condition. We test annunciators during PM1 by triggering known alarm conditions at controller and verifying correct indication at remote panel. Test includes all alarm points not just general alarm. Only functional testing under actual alarm conditions proves annunciator will alert personnel during real emergencies. Panel that appears normal during routine inspection may provide no warning during critical generator faults when notification is essential.

Frequently Asked Questions

What causes remote annunciator communication failures?

Damaged wiring from construction work or rodent damage breaks signal paths. Corroded connections create intermittent signal loss. Incorrect wiring polarity or miswired terminals prevent proper communication. Communication protocol mismatch between controller and annunciator. Power supply voltage outside annunciator specifications. Electrical noise from VFDs or welding equipment interferes with signals. Failed communication modules in controller or annunciator. Configuration errors in controller alarm mapping. Most failures are wiring or connection related rather than electronic component failure.

Can I add additional remote annunciator panels?

Depends on controller capabilities and communication method. Some controllers support multiple annunciator outputs through relay contacts or digital communication buses. Adding panels may require additional controller modules or signal amplifiers. Hardwired relay systems limited by contact rating and wire size. Digital communication systems typically support multiple devices on same bus. Consult generator manufacturer for expansion capabilities and proper installation procedures. Improper additions can cause all annunciators to malfunction or overload controller outputs.

Why test annunciators when generator is running properly?

Testing verifies annunciators will function during actual emergencies when notification is critical. Communication failures often go undetected until alarm condition occurs. Wiring damage from construction or maintenance may have occurred since last test. Configuration changes to controller may have disrupted annunciator operation. Personnel turnover means new staff may not recognize alarm indications. Regular testing ensures everyone understands what different alarms mean and proper response procedures. Annunciator that fails during test can be repaired before emergency. Annunciator that fails during actual outage leaves personnel unaware of generator problems until too late.

What is difference between hardwired and digital communication annunciators?

Hardwired annunciators use dedicated relay contacts from controller for each alarm point. Simple and reliable but limited by number of available relay outputs. Each alarm requires separate wire pair creating large wiring bundles for long distances. Digital annunciators communicate via protocol like Modbus or SNMP over single communication cable. Support hundreds of alarm points on two wire connection. Allow integration with building automation systems. Require proper configuration and more complex troubleshooting. Digital systems more flexible but hardwired more reliable in electrically noisy environments.

Service Request

Still have questions?

Generator Source specializes in low-hour, used, new, and surplus generator sets. We have a wide variety of generator sizes and models to fit any project. We are not a broker, we own what we sell.

Call us today (877-866-6895) or click Contact Us to be connected with one of our experienced sales reps.

We have 350+ generators in stock and ready to ship!