System Function

In an internal combustion engine a turbocharger is a forced induction device that compresses the intake air forcing more air into the engine in order to produce more power for a given displacement. When turbo performance drops, airflow decreases which reduces power and increases stress on the engine under load.

- Boost Pressure Generation: The turbocharger uses exhaust gas energy to spin a turbine connected to compressor wheel that pressurizes intake air allowing more fuel to be burned per combustion cycle.

- Power Density Enhancement: By forcing compressed air into cylinders the turbocharger allows smaller displacement engines to produce power equivalent to much larger naturally aspirated engines.

Oil contamination, air or oil leaks, or compressor damage can cause unusual whine, smoke and sluggish response during load changes. In more severe cases the generator may struggle to carry load or trigger protective alarms.

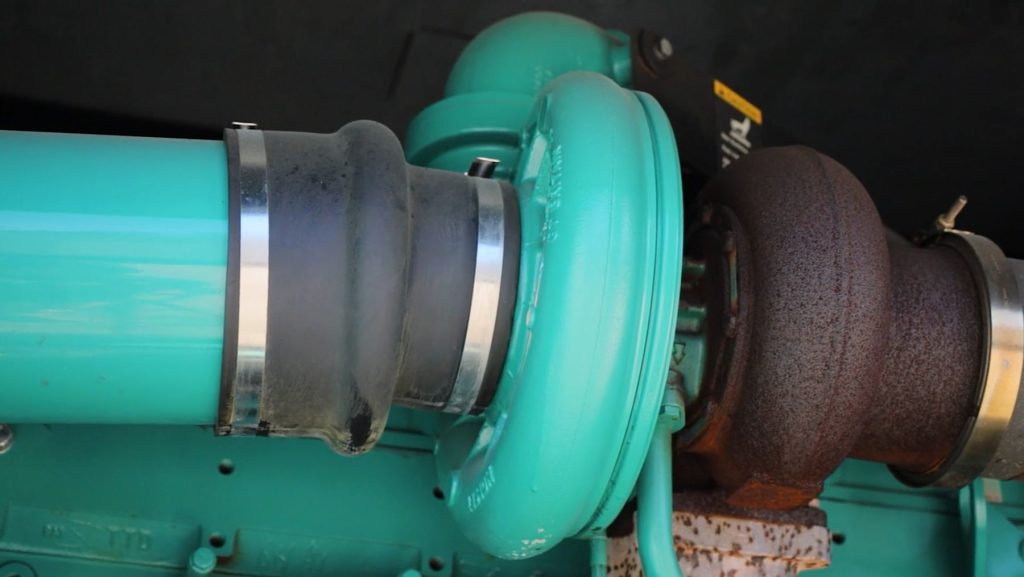

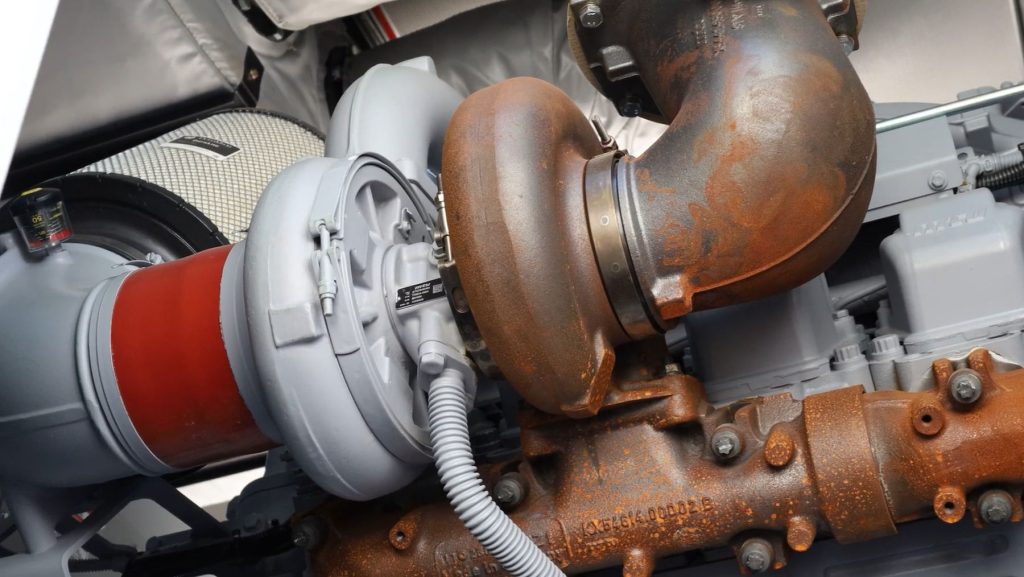

Turbocharger inspection video

Maintenance Schedule

How often should it be inspected?

Turbochargers are inspected for air leaks, abnormal noise, fluid leaks, and shaft play indicators every quarter during PM1 inspections—not just whether the engine starts. Turbochargers typically can be rebuilt or replaced based on operating hours and condition testing.

Environmental Considerations: Turbochargers on generators operating in dusty environments experience accelerated compressor wheel erosion from abrasive particles. High ambient temperatures reduce turbocharger efficiency and cooling effectiveness. Generators with frequent load cycling experience more severe thermal stress accelerating bearing wear. Coastal environments accelerate corrosion of turbine housing and components.

How you can tell it is acting up

- Unusual Whining or Whistling: High pitched noise from turbocharger area indicating bearing wear or compressor wheel damage.

- Blue or Black Smoke: Excessive smoke during operation revealing oil consumption from failed turbo seals or incomplete combustion from boost problems.

- Loss of Power Under Load: Generator cannot carry rated load or labors during loading indicating insufficient boost pressure from turbocharger problems.

- Oil Leaks Around Turbo: Visible oil seepage at turbocharger connections revealing seal failure or excessive crankcase pressure.

- Sluggish Throttle Response: Delayed power increase when load applied suggesting turbo lag from bearing wear or compressor damage.

Most asked question

“My turbo is making a slight whining sound but the generator still runs—should I be concerned?”

Absolutely. Turbocharger noise indicates bearing wear or developing damage. Turbochargers spin at speeds exceeding 100,000 RPM requiring perfect balance and lubrication. Any unusual noise suggests bearing clearances have increased allowing shaft movement that creates imbalance. As wear progresses, compressor or turbine wheels can contact housings causing catastrophic failure that sends metal fragments into engine intake or exhaust systems. Failed turbochargers often damage intake manifolds, intercoolers and occasionally engine valves or pistons. Operating with noisy turbocharger risks expensive secondary damage. We inspect turbochargers during PM1 checking for shaft play, oil leaks and unusual sounds. Turbochargers showing any abnormal noise should be removed for inspection or replacement before catastrophic failure occurs during emergency operation.

Frequently Asked Questions

How long do turbochargers typically last?

Turbocharger life varies dramatically based on maintenance and operating conditions. Well maintained turbochargers with clean oil and proper operating procedures can last 15,000 to 20,000 hours. However turbochargers on generators with neglected oil changes contaminated air intake or frequent cold starts may fail in 5,000 hours or less. Most turbocharger failures result from oil starvation, contaminated oil, or foreign object damage to compressor wheel. Regular oil changes with correct oil grade and proper air filtration are critical for turbocharger longevity.

What causes turbocharger failure?

Oil contamination or oil starvation is primary cause. Dirty oil contains abrasive particles that damage journal bearings causing excessive clearance and shaft play. Delayed oil changes allow oil to break down losing lubrication properties. Cold starts without proper warm-up prevent oil from reaching bearings quickly. Foreign object damage from failed air filter or loose intake components destroys compressor wheels. Exhaust restrictions from carbon buildup create backpressure overloading turbine bearings. Hot shutdowns without cooldown period cause oil coking in bearing passages.

Can turbochargers be rebuilt or must they be replaced?

Many turbochargers can be professionally rebuilt replacing bearings, seals and sometimes compressor or turbine wheels. Quality rebuild typically costs 40 to 60 percent of new turbocharger price. However rebuild quality varies significantly between shops. Critical standby generators should use OEM rebuilt or new turbochargers for reliability. Rebuilt turbochargers from unknown sources may have short service life. Turbochargers with damaged housings or severe shaft wear may not be rebuildable. Consider generator age and value when deciding between rebuild and replacement.

Why is proper cooldown important for turbocharged engines?

Turbochargers run extremely hot reaching turbine temperatures over 1500F during loaded operation. Immediate shutdown after load causes oil in bearing passages to overheat and carbonize coating bearings with hard deposits. This oil coking restricts oil flow during next start accelerating bearing wear. Proper cooldown involves running engine at idle for 3 to 5 minutes allowing turbocharger to slow and cool before shutdown. This cooldown period allows oil to circulate removing heat and preventing coking. Many modern generators have electronic cooldown timers that automatically idle engine before shutdown protecting turbocharger.

Service Request

Still have questions?

Generator Source specializes in low-hour, used, new, and surplus generator sets. We have a wide variety of generator sizes and models to fit any project. We are not a broker, we own what we sell.

Call us today (877-866-6895) or click Contact Us to be connected with one of our experienced sales reps.

We have 350+ generators in stock and ready to ship!