System Function

Voltage is the electrical potential the generator produces to run connected equipment and it needs to stay steady as the load changes. When voltage is unregulated damage can occur down the line to components being powered by the generator.

- Voltage Regulation: The automatic voltage regulator AVR monitors generator output voltage and adjusts alternator excitation to maintain stable voltage typically 120/208V or 277/480V despite varying electrical loads.

- Load Response: Quick voltage regulation prevents voltage droop when loads are applied and voltage rise when loads are removed protecting sensitive equipment from damaging voltage excursions.

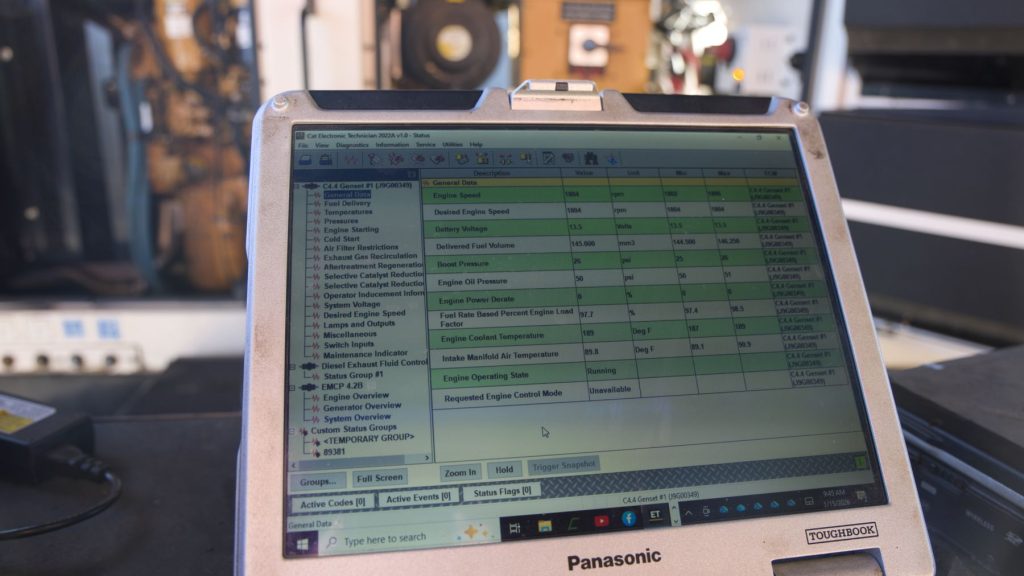

This is why voltage is verified during service at the terminals and under load with calibrated meters not just watched on the controller display.

Voltage regulation testing & maintenance video

Maintenance Schedule

How often should it be verified?

How often should it be load tested?

Voltage is verified at terminals and under load with calibrated meters every quarter during PM1 inspections. Annual load bank testing during PM2 verifies voltage regulation under realistic load conditions proving proper AVR operation.

Environmental Considerations: AVRs in electrically noisy environments may experience interference affecting regulation accuracy. High temperatures accelerate electronic component aging in voltage regulators. Moisture intrusion damages AVR circuit boards. Voltage sensing wiring subject to damage from rodents or construction activity creating voltage regulation problems.

How you can tell it is acting up

- Voltage Fluctuation: Output voltage varies significantly during steady load operation indicating AVR problems or alternator issues.

- High or Low Voltage: Steady voltage output outside acceptable range 120V plus or minus 5 percent indicating AVR failure or incorrect settings.

- Voltage Unbalance: Significant voltage difference between phases indicating alternator winding problems or unbalanced load distribution.

- Equipment Damage: Connected devices experiencing failures or shortened lifespan from voltage problems.

- Dimming or Flickering Lights: Lights brighten or dim during load changes revealing inadequate voltage regulation.

Most asked question

“The controller shows 120V—does that mean voltage regulation is working properly?”

Not necessarily. Controller displays show nominal voltage but may not reflect actual output voltage accurately. Voltage at generator terminals can differ from voltage at controller measurement point due to voltage drop in wiring. More critically controller cannot reveal how voltage responds to load changes. A generator maintaining perfect voltage at no load may have serious regulation problems when asked to carry load. Voltage may drop excessively during load application or overshoot during load removal damaging sensitive equipment. We verify voltage during PM1 using calibrated meters at generator output terminals. Annual load bank testing during PM2 proves voltage regulation maintains stable output within 5 percent during load application and rejection sequences. Only testing under actual load conditions reveals whether voltage regulation will protect your equipment during emergency operation.

Frequently Asked Questions

What causes poor voltage regulation?

AVR component failure is common cause. Electronic components age over time losing accuracy. Sensing circuit problems prevent AVR from measuring output voltage correctly. Alternator excitation winding failures prevent AVR from controlling voltage. Rotating diode failures in brushless alternators. Poor connections in voltage sensing circuits. Alternator winding problems. Incorrect AVR settings or wrong AVR for application. Many regulation problems are AVR related but alternator condition must be verified before AVR replacement.

Why does voltage drop when load is applied?

Some voltage droop during load application is normal as generator responds to sudden power demand. Excessive droop indicates sluggish AVR response alternator winding problems or governor hunting causing speed variations that affect voltage. Acceptable voltage droop is typically less than 5 percent during full load step and should recover within 5 seconds. Excessive droop may cause equipment to malfunction or shutdown. Load bank testing reveals actual droop characteristics allowing diagnosis and correction.

Can voltage regulation damage my equipment?

Absolutely. High voltage damages electronic equipment by exceeding component voltage ratings causing immediate failure or shortened lifespan. Low voltage causes motors to draw excessive current overheating windings and reducing motor life. Voltage fluctuations cause computer power supplies to work harder reducing efficiency and reliability. Medical equipment may provide inaccurate readings or shutdown from unstable power. Variable frequency drives fault from voltage variation. Proper voltage regulation is critical for protecting connected equipment investment and ensuring reliable facility operation during outages.

How often should voltage regulation be tested?

Verify voltage quarterly during PM1 inspections using calibrated meters at generator output terminals under load. Annual load bank testing during PM2 required to prove regulation under realistic conditions. Load bank testing applies actual electrical load allowing observation of voltage response during load steps. Portable generator testing cannot reveal regulation problems that only appear under sustained load. Critical facilities should perform more frequent load bank testing to ensure voltage regulation meets equipment requirements.

Service Request

Still have questions?

Generator Source specializes in low-hour, used, new, and surplus generator sets. We have a wide variety of generator sizes and models to fit any project. We are not a broker, we own what we sell.

Call us today (877-866-6895) or click Contact Us to be connected with one of our experienced sales reps.

We have 350+ generators in stock and ready to ship!