System Function

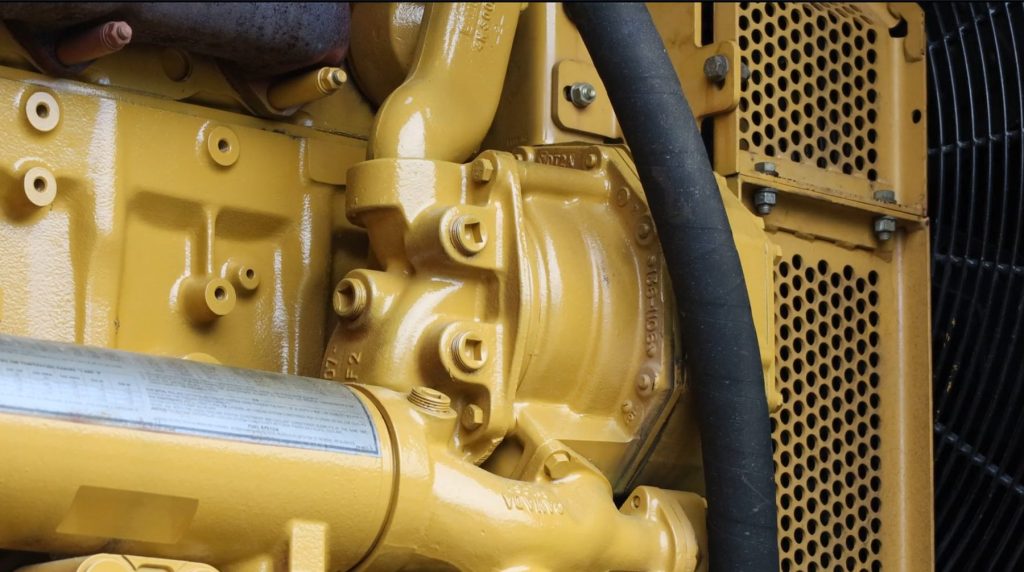

The water pump circulates coolant throughout the engine and radiator so heat can be removed consistently during operation. Proper flow prevents temperature spikes and helps the generator stay stable during longer run times under load. When the water pump starts to fail coolant flow drops and the engine can overheat quickly especially during sustained load.

- Coolant Circulation: The water pump impeller creates pressure differential forcing coolant to flow through engine block, cylinder heads and radiator maintaining even temperature distribution throughout cooling system.

- Flow Rate Maintenance: Pump must deliver adequate flow volume typically 50 to 200 GPM depending on engine size to transfer heat from engine to radiator effectively under all operating conditions.

Bearing and seal problems often show up as noise, wobble or coolant residue at the pump weep area. Reduced circulation can also create hotspots that trigger alarms and shutdowns even when coolant level looks normal.

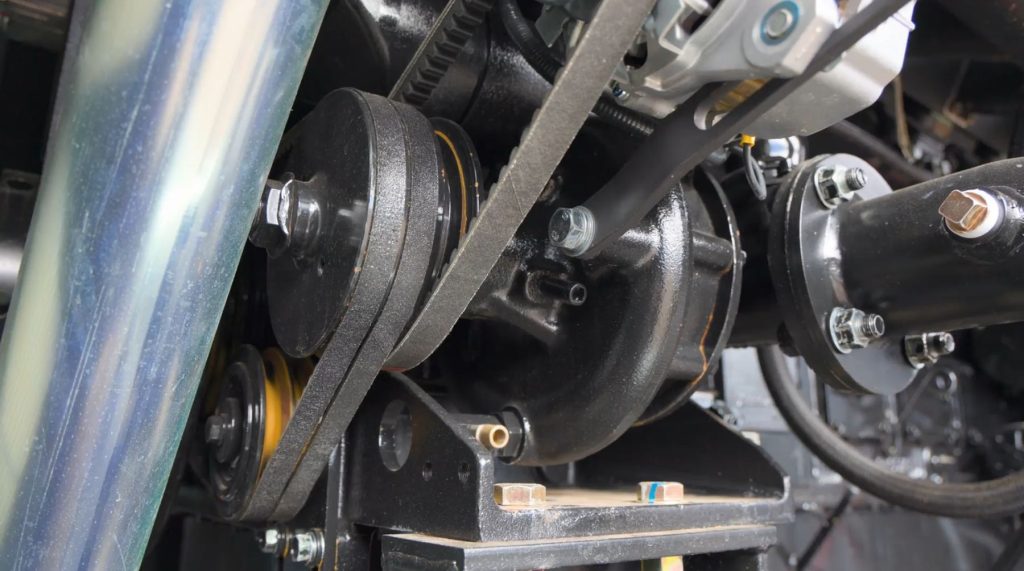

Water pump maintenance video

Maintenance Schedule

How often should it be inspected?

Water pumps are inspected for leaks, bearing noise and shaft play every quarter during PM1 inspections—not just assumed good because the coolant is full.

Environmental Considerations: Water pumps in systems using plain water or contaminated coolant experience accelerated corrosion and seal wear. Hard water causes mineral deposits on impeller reducing efficiency. Pumps operating with improper coolant concentration experience cavitation damage. Systems with inadequate coolant causing frequent overheating stress pump seals and bearings.

How you can tell it is acting up

- Coolant Leaks at Pump: Visible coolant seepage from weep hole or gasket surfaces indicating seal failure.

- Bearing Noise: Growling or squealing sound from water pump area increasing with engine RPM revealing bearing wear.

- Shaft Play: Visible wobble or movement when pump pulley pushed by hand indicating bearing failure.

- Overheating Under Load: Engine temperature rises above normal during loaded operation despite adequate coolant level suggesting inadequate coolant circulation.

- Loose or Wobbling Pulley: Water pump pulley appears loose or runs eccentrically indicating bearing failure or loose mounting.

Most asked question

“I see slight coolant seepage at the water pump but no major leak—can I wait to replace it?”

No. Minor seepage from water pump weep hole indicates seal failure and impending catastrophic failure. Weep holes are designed to reveal seal problems before internal bearing damage occurs. Once seal fails coolant enters bearing cavity washing away lubrication and causing rapid bearing wear. Small leak today typically becomes complete bearing seizure within weeks or months. Seized water pump stops coolant circulation causing immediate overheating and potential engine damage. Catastrophic pump failure during emergency operation when you need reliable cooling leaves your facility without backup power. Water pumps showing any seepage should be replaced immediately. Scheduled pump replacement during PM service costs far less than emergency repair plus facility downtime from overheating failure during actual power outage.

Frequently Asked Questions

How long do water pumps typically last?

Water pump lifespan varies by coolant quality and operating conditions. Pumps operating in systems with proper coolant and regular maintenance typically last 5 to 7 years or 8,000 to 12,000 operating hours. Pumps in systems with contaminated coolant, hard water or inadequate corrosion inhibitors may fail in 3 years or less. Generators with infrequent operation may experience seal drying and premature failure. Most pump failures result from seal deterioration or bearing wear rather than impeller damage. Proper coolant maintenance dramatically extends water pump life.

What causes water pump failure?

Seal deterioration from age heat or chemical degradation is primary cause. Coolant contamination with oil or debris damages seals and bearings. Improper coolant concentration allows corrosion and cavitation. Over-tightened belts create excessive bearing load. Misaligned pulleys create side loads on bearings. Contaminated coolant acts as abrasive wearing impeller and seals. Cold starts with inadequate warmup prevent proper thermal expansion of seals. Overheating from system problems stresses pump components. Most failures are preventable through proper coolant maintenance and belt tension.

Can water pumps be rebuilt or must they be replaced?

Most generator water pumps are replaced as complete assemblies rather than rebuilt. Rebuild kits may be available but typically include only seal and gasket replacement. Bearing replacement requires pressing operations and specialized tools. Labor cost for rebuilding often approaches cost of new pump. New pump includes fresh bearings, seals and impeller with warranty. For critical standby generators replacement with new pump provides better reliability than rebuild. Replace pump whenever seal leaks or bearing noise develops regardless of age.

Why is proper coolant important for water pump life?

Correct coolant mixture provides corrosion inhibitors protecting pump housing and impeller from rust and electrolytic corrosion. Antifreeze in coolant prevents cavitation damage from localized boiling on impeller surfaces. Proper inhibitor concentration maintains seal elasticity preventing premature hardening and leakage. Contaminated or degraded coolant acts as abrasive wearing pump seals and bearings. Plain water without inhibitors causes rapid corrosion and pump failure. Coolant should be tested annually and replaced every 3 to 5 years maintaining protective properties that extend water pump service life.

Service Request

Still have questions?

Generator Source specializes in low-hour, used, new, and surplus generator sets. We have a wide variety of generator sizes and models to fit any project. We are not a broker, we own what we sell.

Call us today (877-866-6895) or click Contact Us to be connected with one of our experienced sales reps.

We have 350+ generators in stock and ready to ship!