The Evolution of Automotive Manufacturing

Automotive manufacturing has a rich history, beginning with Karl Benz’s creation of the first internal combustion engine automobile in 1885. Henry Ford revolutionized the industry in 1908 with the introduction of the Model T and assembly line production, significantly reducing costs and making cars accessible to the masses.

Over the decades, advancements like automatic transmissions, hydraulic brakes, and independent suspension systems have shaped modern vehicles. During WWII, auto production paused as factories pivoted to support the war effort, producing military vehicles and aircraft. Post-war, the industry resumed and continued innovating, leading to today’s complex automotive manufacturing ecosystem.

Modern Automotive Manufacturing Facilities

The U.S. is home to 14 major automotive manufacturers operating approximately 104 manufacturing facilities. These plants rely on a vast network of suppliers for:

- Engines (e.g., Cummins for Nissan and Chrysler)

- Components (belts, spark plugs, injectors)

- Tires (all-season, mud, and snow options)

- Bearings (supplied by Timken, NSK, and NTN)

Advancements in automation have transformed these factories. Robotic arms and material handling systems dominate production lines, ensuring efficiency and precision. Any interruption in these interconnected systems can halt production, emphasizing the importance of dependable support systems.

Auxiliary and Support Systems in Manufacturing

Supporting systems like compressed air, HVAC, and emergency power ensure factories remain operational. For example, large air compressors rely on cooling systems to function properly. Without these, many facilities face downtime or shutdowns. Similarly, controlled environments for temperature and humidity are critical for certain manufacturing processes.

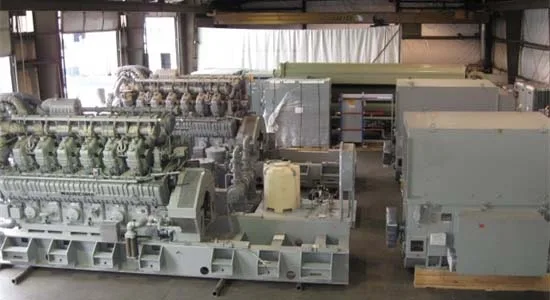

When utility power fails due to storms or grid issues, backup generators are essential. These systems, governed by regulations like those from the National Fire Protection Association (NFPA), must meet peak electrical demands and undergo rigorous maintenance.

Power Solutions for Automotive Manufacturing

At Generator Source, we understand the critical need for reliable power in manufacturing. With over 35 years of experience, we offer:

- A wide inventory of new and pre-owned generators, all inspected through a 31-point quality check.

- Maintenance services, including load testing and troubleshooting.

- Rapid shipment options, often within 24 hours.

Dependable power ensures that automotive manufacturing facilities can maintain productivity, even during utility outages. Explore our Inventory or Contact Us today for tailored power solutions.