Generator Source | Powering Industries for 50+ Years

Industrial Generator Diesel Fuel Delivery

Diesel Fuel Maintenance Guide

A comprehensive fuel maintenance program is the single most important factor in ensuring your standby power system is reliable and ready for an emergency. With 50+ years of experience, Generator Source has seen firsthand how neglected fuel can lead to catastrophic failures. This guide explains why fuel maintenance is so critical and outlines the expert services we provide to keep your operations running.

- Schedule Fuel Delivery

- Why Is Diesel Fuel Maintenance Crucial for Your Generator?

- The Core Fuel-Related Risks to Your Standby Generator

- Key Components of a Comprehensive Fuel Maintenance Program

- Generator Source’s Fuel Maintenance Services

- Industry Standards for Fuel Maintenance (NFPA, TJC, ASTM)

- 24/7 Emergency Fuel Delivery Service

Why Is Diesel Fuel Maintenance Crucial for Your Generator?

For industrial and commercial facilities, a standby generator isn’t just a convenience; it’s a critical asset that ensures continuity, safety, and operational integrity during a power outage. However, the most common reason for a standby generator to fail is not mechanical breakdown, but an issue with its diesel fuel.

Unlike the gasoline in your car, which is typically used and replenished weekly, the diesel fuel in a standby generator can sit in a storage tank for months or even years. Over time, it degrades. Water contamination, microbial growth, and chemical instability can turn perfectly good fuel into a sludge-like substance that will clog filters, damage engine components, and prevent the generator from starting when you need it most.

At Generator Source, our EGSA-certified technicians understand that proactive fuel maintenance isn’t just a recommended best practice—it’s essential for ensuring the long-term reliability of your power system.

The Core Fuel-Related Risks to Your Standby Generator

Diesel fuel is an organic fluid with a limited shelf life. Without proper management, it is susceptible to several critical threats:

- Water Contamination Management: Steel tanks are prone to “sweating” due to temperature fluctuations, causing condensation to form inside the tank. This water accumulates at the tank bottom, fostering microbial growth like bacteria and fungi, which leads to sludge, corrosive acids, and fuel degradation. Our service tackles this by regularly inspecting and draining water from tanks, polishing fuel to remove contaminants, and applying treatments to prevent microbial growth, ensuring your diesel fuel remains clean and your generator operates reliably.

- Microbial Growth (The “Diesel Bug”): Bacteria, algae, and fungi thrive in the presence of water. As these microbes multiply, they create a biofilm and biomass that clogs fuel filters and lines, leading to engine starvation and shutdown.

- Oxidation and Instability: As fuel ages, it reacts with oxygen, causing it to darken and form sediments and varnishes. This process accelerates in the presence of heat and contaminants, reducing the fuel’s ignition quality and leading to poor engine performance.

- Sedimentation and Sludge: Particulates from rust, dirt, and the byproducts of microbial growth and oxidation settle at the bottom of the tank, forming a thick sludge. During operation, this sludge can be drawn into the fuel system, causing catastrophic damage to fuel injectors and pumps.

Key Components of a Comprehensive Fuel Maintenance Program

A proactive fuel maintenance program from Generator Source is designed to address these risks head-on. Our approach is built on three pillars:

- Fuel Sampling and Analysis: You can’t fix what you don’t measure. We start by taking a sample of your fuel and sending it to a specialized lab for analysis. This “blood test” for your fuel tells us about its condition, including water content, microbial contamination, and sediment levels. This data allows us to create a targeted treatment plan.

- Fuel Polishing (Filtration): Fuel polishing is a sophisticated cleaning process that circulates the fuel through a series of filters to remove sediment, and microbial contaminants down to a microscopic level. It’s like dialysis for your fuel tank. Our mobile filtration systems can restore your degraded fuel to a clean, stable state without needing to empty and dispose of it, saving you time and money.

- Fuel Additives (Stabilization): Once the fuel is clean, we use chemical additives to keep it that way. Biocides prevent future microbial growth, while stabilizers inhibit oxidation and corrosion. This extends the life of your fuel and protects your entire fuel system.

Generator Source’s Fuel Maintenance Services

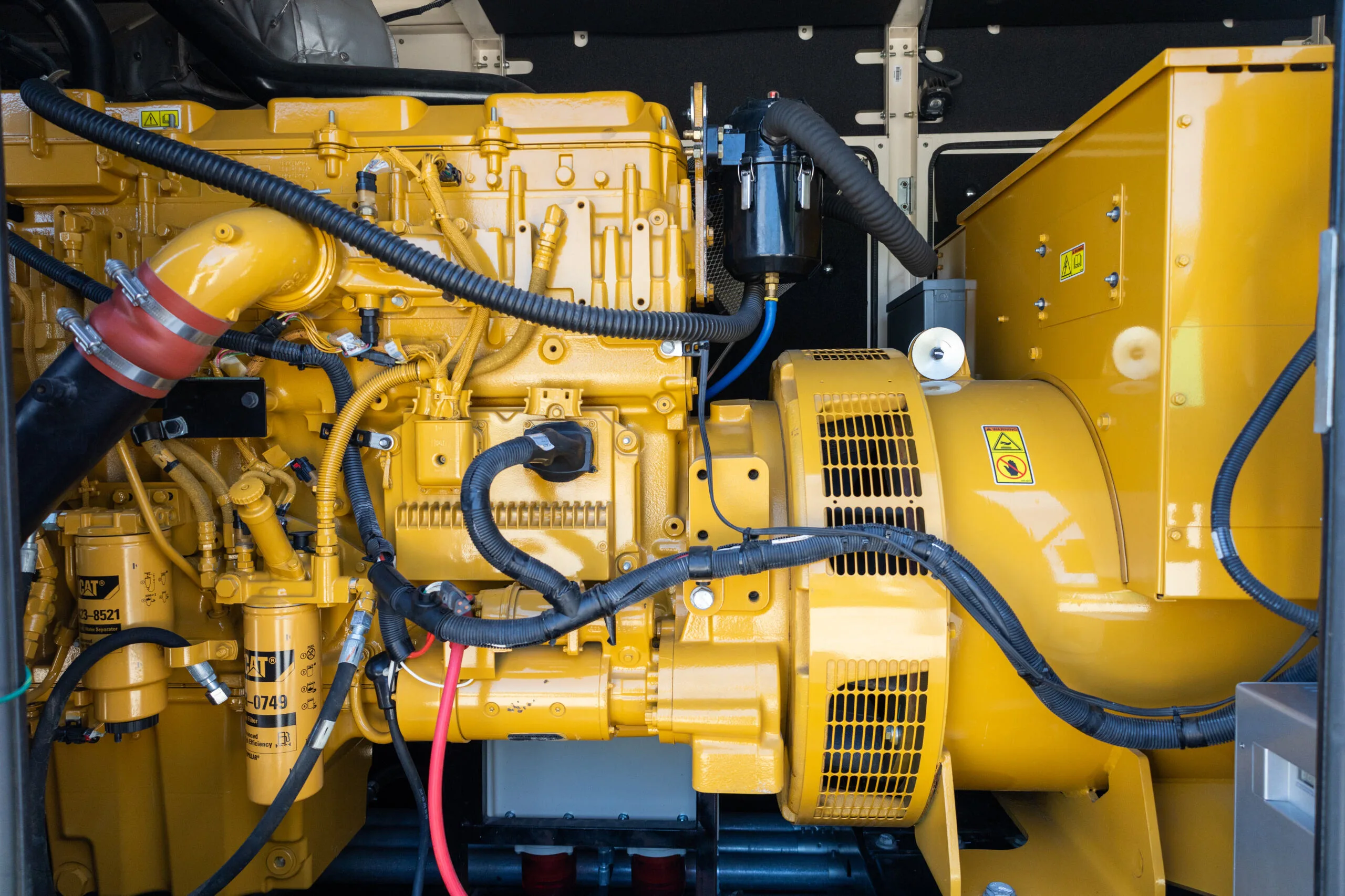

With 50+ years of experience, Generator Source offers a complete, one-stop solution for all your generator needs. Our fuel maintenance service is a critical part of our commitment to your power system’s reliability. Whether you have a Caterpillar, Cummins, Generac, Kohler, MTU, or any other major brand, our expert technicians have you covered.

Our comprehensive fuel service includes:

- Scheduled Fuel Testing: Regular analysis to monitor fuel quality and catch problems early.

- On-Site Fuel Polishing: We bring our advanced filtration equipment to you, ensuring minimal disruption to your operations.

- Water and Sediment Removal: Physically removing harmful contaminants from the bottom of your storage tank.

- Biocide and Stabilizer Treatments: Protecting your fuel and ensuring it’s ready for long-term storage.

- 24/7 Emergency Service: If your generator fails to start, our rapid-response team is available around the clock to diagnose and resolve the issue.

Still have questions or looking for more information?

Generator Source specializes in low-hour, used, new, and surplus generator sets. We have a wide variety of generator sizes and models to fit any project. We are not a broker, we own what we sell.

Call us today (877-866-6895) or click Contact Us to be connected with one of our experienced sales reps.

We have 350+ generators in stock and ready to ship!

Industry Standards for Fuel Maintenance (NFPA, TJC, ASTM)

For many facilities, particularly in healthcare and data centers, regular fuel testing is not just a recommendation—it’s a requirement. Key industry standards mandate fuel quality and maintenance schedules:

- NFPA 110 (Standard for Emergency and Standby Power Systems): This is the gold standard for generator readiness. It requires annual testing of stored diesel fuel for properties like water and sediment, specific gravity, and microbial contamination.

- The Joint Commission (TJC): For accredited hospitals, TJC standards align closely with NFPA 110, requiring documentation of fuel quality as part of their environment of care standards.

- ASTM D975 (Standard Specification for Diesel Fuel Oils): This standard defines the quality requirements for diesel fuel. Our lab tests compare your fuel against these benchmarks to ensure it meets the specifications for reliable engine performance.

Generator Source ensures that your fuel maintenance program meets or exceeds all these regulatory requirements, providing you with the documentation and peace of mind you need.

24/7 Emergency Fuel Delivery

Rapid, Reliable Fueling to Keep Your Generators Running

Ensure your business stays powered during critical moments with our 24/7 Emergency Fuel Delivery service. Whether you’re managing a small operation or a large facility, unexpected power outages can disrupt operations, risk safety, and impact your bottom line. Our team at Generator Source is ready around the clock to deliver high-quality diesel fuel to your generators, keeping your backup power system primed for any emergency.

Why Choose Our Emergency Fuel Delivery?

- Immediate Response: Power outages don’t wait, and neither do we. Call 877-866-6895 anytime, day or night, to schedule rapid fuel delivery.

- Protect Your Operations: Avoid costly downtime, spoilage of perishables, data loss, or compromised safety at healthcare, industrial, or commercial facilities.

- High-Quality Diesel Fuel: Our stable, long-lasting diesel fuel ensures your generators perform reliably, with less maintenance and a longer lifespan compared to natural gas alternatives.

- Expert Service: Our experienced fuel professionals deliver and monitor fuel quality, preventing issues like water contamination or wet stacking that can harm your equipment.

Your standby generator is a significant investment. Protecting that investment requires a proactive, professional approach to fuel maintenance. Don’t wait for a power outage to discover that your fuel has gone bad.

Fuel System Case Studies & Articles

Florida Team Training Spotlight – Generator Fuel Testing

Keeping generators reliable starts long before an outage ever happens. Recently, our Jacksonville, F…

Generator Fuel Tanks and Base Tank Options

Written by Dakotah Merkley – Senior Vice President of Generator Source Why Fuel Tanks Matter When pe…

Why Property Managers Must Keep Backup Generators Well-Maintained

Key Takeaways by: Mark Marar | Colorado Field Services Managerappears in: The Colorado Real Estate J…

The Hidden Cost of Power

Is Your Generator Draining Your Wallet? Ever wonder why some industrial generators seem to run with …

The Administration’s Fuel Plans: What They Mean for Industrial Generator Users

The U.S. administration’s recent push to ramp up fossil fuel production is poised to shake up the en…

Storing Diesel Fuel – What You Need to Know

Did you know the average lifespan of diesel fuel is only 6 to 12 months? When storing diesel fuel, i…

Other Industrial Generator Services Offered

Automatic Transfer Switch (ATS) Services

- Expert ATS sizing and installation assistance

- Site preparation and planning for seamless integration

- Customized solutions for various backup power scenarios

Control Panel Installations & Upgrades

- Implement advanced monitoring and control systems

- Compatible with major brands: Deep Sea Electronics, Woodward Controllers, Caterpillar EMCP, Cummins Power Command

- Enhance remote monitoring, load sharing, and peak shaving capabilities

Custom Generator Fabrication

- Skilled fabricators for unique power generation projects

- Customized trailers, enclosures, and specialized equipment

- Turn your power generation concept into reality

Generator Battery Services (outside of scheduled PM)

- Comprehensive battery testing and replacements

- Partnerships with leading battery suppliers

- Ensure reliable starts and consistent performance

Generator Frequency Conversions

- Specialized 60 Hz to 50 Hz conversions for international operations

- Engine modifications and third-party frequency converter installations

- Customized solutions for global power requirements

Generator Oil Analysis

- On-site and lab-partnered oil testing

- Rapid results for informed maintenance decisions

- Proactive approach to generator health and longevity

Generator Painting and Aesthetics

- High-quality painting services for generator refurbishment

- Enhance the appearance of your power equipment

- Protect your generator from environmental factors

Industrial Generator System Sizing

- On-site analysis and customized power planning

- Expert consultations for optimal generator sizing

- Engineering services for complex power requirements

Load Bank Testing for Generators (outside of scheduled PM)

- Generator phase conversions

- Tailored solutions to meet changing power distribution needs

- Complimentary testing for all generator sales

- On-site load bank testing services for larger industrial generators

- Ensure optimal performance and reliability under various load conditions

Voltage ChangesControl Panel Installations & Upgrades

- Convert between 480V and 277V configurations

- Hourly rate service available for all customers

- Expert assessment of generator reconfiguration possibilities

Voltage Regulator Replacements

- Diagnostics and replacement for malfunctioning regulators

- Upgrades to meet specific voltage regulation requirements

- Expertise in both self-contained and separate regulator systems

Other Services

- Paralleling configurations for increased power capacity

- Transformer installation and configuration

- On-site troubleshooting for rapid issue resolution

- Customized planned maintenance programs