Industry: Agriculture and food production

Delivery location: Birdsboro, Pennsylvania

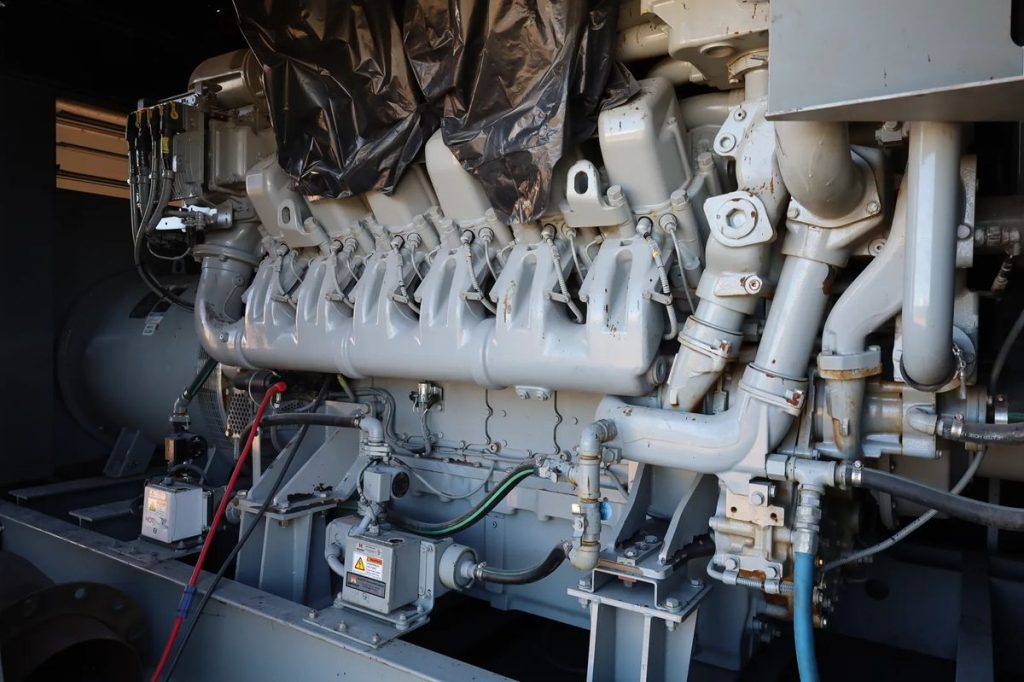

Generator supplied: Katolight industrial diesel generator

Capacity: 1250kW

Make: MTU

Fuel type: Diesel

Voltage: 277/480V

Housing: Sound-attenuated enclosure

Application: Backup power for agricultural processing and operations

Outcome: Delivered a high-capacity generator to support operational continuity and protect production processes

The Challenge

An agricultural operation in eastern Pennsylvania required a reliable backup power solution to support critical processing and operational systems.

Agricultural and food production environments depend heavily on continuous power to maintain processing schedules, environmental controls, and equipment operation. Power interruptions can lead to production delays, product loss, or operational disruption.

The generator needed to deliver sufficient capacity, integrate with existing electrical infrastructure, and operate reliably in an active agricultural setting.

Why It Mattered

In agricultural and food production facilities, power reliability directly affects product quality, safety, and operational efficiency.

For this application, it was important that the backup generator:

- Delivered adequate capacity for processing and support systems

- Operated reliably during extended outages

- Integrated cleanly with existing 277/480V electrical systems

- Minimized operational disruption when running

Backup power served as a safeguard for both production continuity and facility resilience.

The Generator Source Solution

Generator Source supplied a 1250kW Katolight industrial diesel generator configured for standby operation in an agricultural environment.

The selected unit featured a sound-attenuated enclosure to reduce noise impact and a diesel platform well suited for high-capacity, industrial-duty applications. Generator sizing and configuration were aligned with the facility’s electrical requirements and operational needs.

By focusing on proven equipment platforms and application fit, Generator Source helped ensure the generator would support reliable operation when utility power was unavailable.

Execution and Delivery

Execution emphasized coordination and reliability.

Generator specifications were confirmed prior to shipment, and freight logistics were coordinated to deliver the unit to the site in eastern Pennsylvania. Clear communication throughout the process helped ensure delivery aligned with site readiness and operational planning.

The generator arrived prepared for integration into the facility’s backup power system.

Results

The operation secured a 1250kW standby generator capable of supporting critical agricultural systems during power outages.

The outcome delivered:

- High-capacity backup power for production and processing systems

- Compatibility with existing electrical infrastructure

- Increased confidence in operational continuity during grid disruptions

The generator now serves as a key component of the facility’s power resiliency strategy.

Ongoing Considerations

For agricultural and food production facilities, Generator Source recommends routine inspections, preventative maintenance, and periodic testing to ensure backup power systems remain ready when needed.

These practices help protect production schedules, equipment performance, and long-term reliability.

Closing

Generator Source supports agricultural and food production operations with dependable backup power solutions designed to protect productivity and continuity. Through proper sizing, proven equipment platforms, and coordinated delivery, our team helps customers prepare for power disruptions with confidence.