Buying an industrial generator is a major investment. Whether the unit is new, surplus, or used, a proper inspection is critical to ensure long-term reliability, safety, and performance. Skipping key inspection steps can lead to unexpected failures, costly repairs, and downtime when power is needed most.

At Generator Source, every generator is professionally inspected and tested before it is sold. Here’s what a proper generator inspection should include and why each step matters.

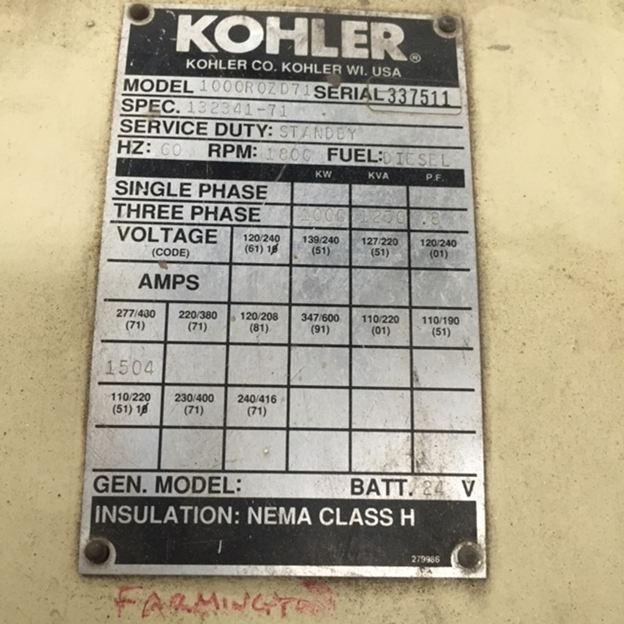

Start With the Generator Data Plate

The inspection process should always begin with the generator data plate. This tag provides essential information about the unit, including:

- Rated capacity in kW

- Voltage and phase configuration

- Frequency

- Serial and model numbers

These details must align with your facility’s electrical requirements and application. A mismatch in voltage, phase, or capacity can lead to improper operation or damage to connected equipment.

Inspect the Engine and Fluids

A visual engine inspection can reveal a great deal about how a generator has been maintained. Key areas to review include:

- Oil condition and level

- Coolant quality and signs of contamination

- Fuel lines and fittings

- Hoses, belts, and clamps

- Evidence of leaks, residue, or overheating

Well-maintained engines typically show clean fluid systems, intact hoses, and minimal corrosion. Excessive buildup or leaks can indicate deferred maintenance or internal issues.

Evaluate Electrical Components and Controls

Electrical health is just as important as mechanical condition. During an inspection, technicians should evaluate:

- Control panel condition and functionality

- Wiring integrity and secure connections

- Breakers and protective devices

- Battery condition and mounting

Loose wiring, corrosion, or damaged components can compromise reliability and create safety risks. Proper inspection ensures the generator will start, operate, and shut down as designed.

Confirm Load Bank Testing Was Performed

A generator that has not been load tested has not truly been proven. Load bank testing verifies that the unit can produce rated power under real operating conditions.

During a load test, technicians confirm:

- Voltage stability

- Frequency control

- Engine response under load

- Cooling system performance

Without load testing, internal issues can remain hidden until the generator is placed into service, often during an emergency.

Review Service History and Documentation

Whenever possible, request maintenance records and inspection documentation. Service history helps confirm how the generator was operated, maintained, and stored. Consistent professional servicing is a strong indicator of long-term reliability.

At Generator Source, every generator is inspected, documented, and tested before it is made available for sale. This process ensures customers know exactly what they are purchasing.

Buy With Confidence

A proper generator inspection is not a quick visual walk-around. It is a structured process that evaluates mechanical condition, electrical integrity, and real-world performance.

When you buy from Generator Source, you are getting more than equipment. You are getting a generator that has been inspected, tested, and prepared by experienced professionals who understand what reliable power truly requires.

If you are considering a generator purchase and want to ensure it meets your operational needs, contact Generator Source to speak with a knowledgeable team member or schedule a professional inspection.